30

Possible status screens are: Access Code REQ, Access Code OK, and Access Code

DIS.

The first indicates that the access code is required to alter settings. The second

indicates that the access code is required and has been entered correctly, and the last

indicates that the access code has been disabled.

Enable Y/N

Use the arrow keys to select Y(Yes) or N(No) and press ENTER to enable or disable

the access code. If the code was enabled, you must enter the access code in order to

disable it.

New Value

Press

ENTER

to display the current access code value and use the arrow keys to

change it to any value between 0 and 9999. If the access code has been enabled, you

will be prompted to enter the current access code before being allowed to change it.

The factory default access code is 1995.

If you change the access code and can't remember it, follow this procedure:

1. Turn off the power to the controller.

2. Wait 10 seconds.

3. Press and hold the Up and Down arrow keys while turning on the power.

4. Read the access code on the display.

5. Release the arrow keys and the code will disappear.

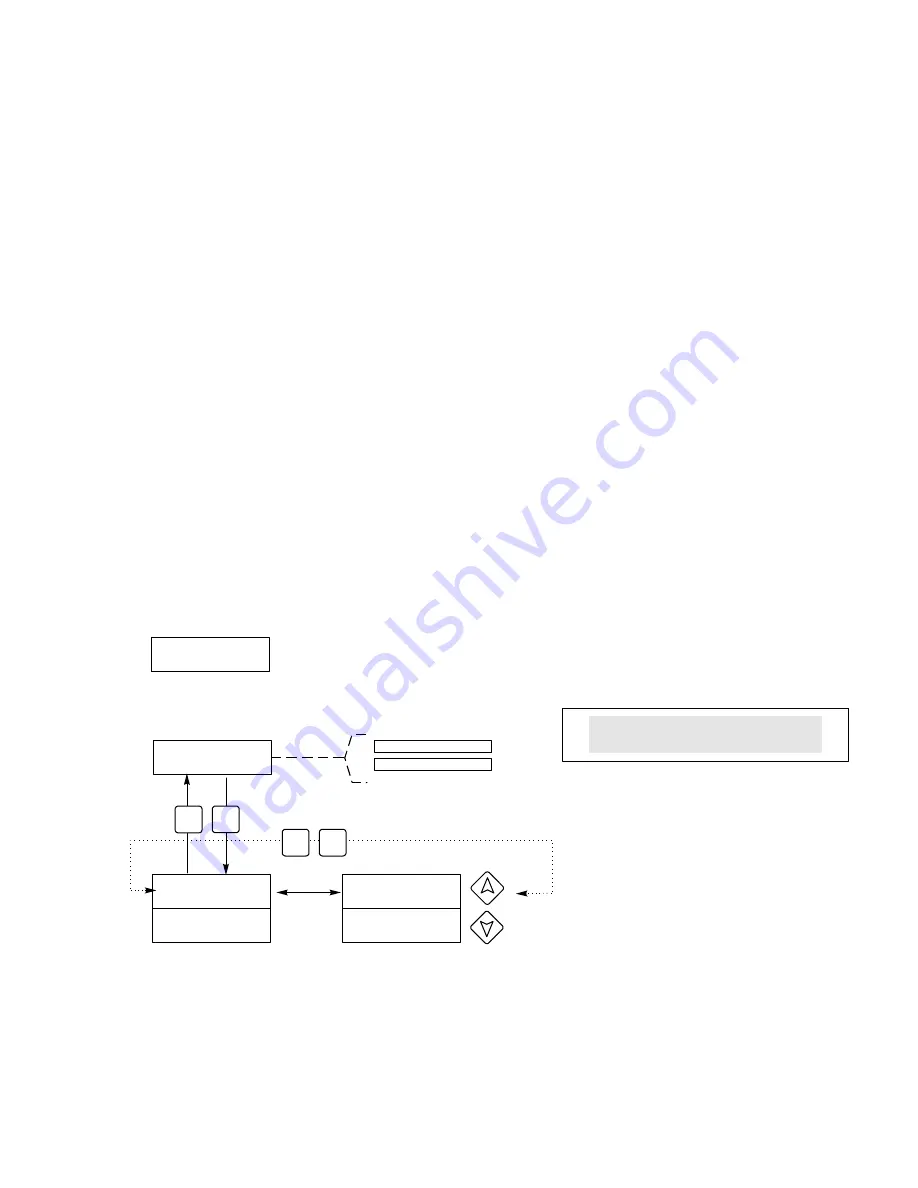

Access Code Menu

Copper 1.98 g/L

Access Code DIS

Any Top Display

Access Code 0000

Access Code DIS

Disable N

Access Code DIS

Disable Y

Access Code DIS

New Value 0

Access Code DIS

New Value 1234

Access Code REQ

Access Code OK

Access Code Menu

Possible status screens

The Access Code prompt may appear at any screen in the entire menu

structure if the current access code has not been entered by the user.

Access code entries will be valid for 10 minutes from the most recent

key press.

Enter any four digit code

E N TER

EX IT

N E X T

P R EV.