10

W 125

GB

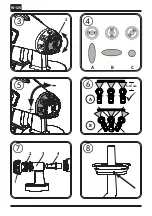

Fig. 4 A

= vertical flat jet

for horizontal surfaces

Fig. 4 B

= horizontal flat jet

for vertical surfaces

Fig. 4 C

= circular jet

for corners, edges and hard-to-reach surfaces

8. Adjusting the Material Volume (Fig. 5)

Adjust the volume of material by turning the union nut from 1 - 8.

9. Spray Technique

•

The spray result depends heavily on the smoothness and cleanliness of the surface to be

sprayed. Therefore the surface should be carefully prepared and kept free of dust.

•

Cover all surfaces not to be sprayed.

•

It is advisable to test the spray gun on cardboard or a similar surface to find the correct

setting.

Important:

Begin spraying outside of the target area and avoid interruptions inside the

target area.

•

Correct (Fig. 6a)

Be sure to hold the spray gun at an even distance of approx. 5 - 15 cm

to the target object.

•

Incorrect (Fig. 6b)

Heavy spray fog build-up, uneven surface quality.

10. Taking Out of Operation and Cleaning

Proper cleaning is the prerequisite for problem-free operation of the paint application

device. No warranty claims are accepted in case of improper or no cleaning. When

processing 2-component varnishes, clean the device immediately.

WARNING! Never hold the spray gun rear part under water or immerse it

into liquids. Clean the housing only with a moistened cloth.

1) Turn off the machine and remove the plug.

2) Unscrew the container. Empty any remaining coating material back into the material

tin.

3) Pull out the suction tube with container seal.

4) Turn the union nut (Fig. 7, 1) beyond the lock at level 1 to remove it. Remove the air

cap (2) and pull out the front section of the gun (3). Pull the nozzle (4) out of the front

part of the spray gun.

CAUTION!

Never clean the spray gun with metal objects.

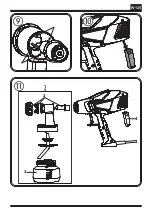

5) Clean all parts carefully using a brush and water or solvent (depending on the material

being processed). Take particular care to ensure that the ventilation hole (Fig. 8) is

clear.

Assembly

1)

1) Insert the nozzle (Fig. 9) into the gun body so that the slots in the nozzle engage in

Insert the nozzle (Fig. 9) into the gun body so that the slots in the nozzle engage in

Содержание W 125

Страница 1: ...wagner group com WOOD METAL SPRAYER W 125 OPERATING INSTRUCTIONS AUS...

Страница 2: ...W 125 A B 7 6 4 5 3 1 2...

Страница 3: ...W 125 d A B C 2 5 15 cm A B 2 1 4 3...

Страница 4: ...W 125 i 1 2 4 3...