12

VERSION 06/2018

ORDER NUMBER DOC 2343275

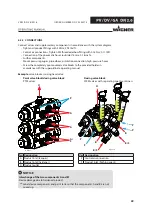

4.2.3 GROUNDING THE UNIT

Hazard due to electrostatic charge!

Explosion hazard and damage to the device.

Friction, flowing liquids and air or electrostatic coating processes create charges. Flames

or sparks can form during discharge.

Correct grounding of the entire spraying system prevents electrostatic charges.

Ensure that all devices and tanks are grounded before each spraying process.

Make sure that the ground and potential equalization of all system parts are

performed reliably and continuously and can withstand the expected stress (e.g.,

mechanical stress, corrosion).

Ground the work pieces to be coated.

Ensure that all persons inside the working area are grounded, e.g., that they are

wearing static dissipative shoes.

Wear static dissipative gloves when spraying. The grounding takes place via the

spray gun handle or the trigger.

4.2.4 PRODUCT HOSES

Hazard due to bursting of product hose!

The product hose is under pressure and may cause dangerous injuries.

Ensure that the hose material is chemically resistant to the sprayed products and

the flushing agents used.

Ensure that the product hoses and the fittings are suitable for the pressure

generated.

Ensure that the following information can be seen on the high-pressure hose:

– manufacturer,

– permissible operating pressure,

– date of manufacture.

Make sure that the hoses are laid only in suitable places. Hoses should not be laid in

the following places under any circumstances:

– in high-traffic areas,

– on sharp edges,

– on moving parts or

– on hot surfaces.

Ensure that the hoses are never run over by vehicles (e.g., fork lifts), or that the

hoses are never put under pressure from the outside in any other way.

Ensure that the hoses are never kinked. Observe maximum bending radii.

Ensure that no work is ever performed with a damaged hose.

Make sure that the hoses are never used to pull or move the equipment.

The electrical resistance of the product hose, measured at both valves, must be less

than 1 MΩ.

Suction hoses may not be subjected to pressure.