ProSpray 22

g

• Secure the spray gun,

refer to the operating manual

of the spray gun.

Clean and remove tip.

For a standard tip, refer to Page 45, Section 13.2.

If a non-standard tip is installed, proceed according to

the relevant operating manual.

1. Remove suction hose from the coating material.

2. Close the relief valve, valve position

SPRAY (

p

spray).

3. Switch the unit ON.

4. Pull the trigger of the spray gun in order to pump the

remaining coating material from the suction hose,

high-pressure hose and the spray gun into an open

container.

5. Immerse suction hose with return hose into a con-

tainer with a suitable cleaning agent.

6. Turn the pressure control knob into the blue zone -

pulsating pressure for unit cleaning.

7. Open the relief valve, valve position PRIME (

k

circu-

lation).

8. Pump a suitable cleaning agent in the circuit for a

few minutes.

9. Close the relief valve, valve position

SPRAY (

p

spray).

10. Pull the trigger of the spray gun.

11. Pump the remaining cleaning agent into an open

container until the unit is empty.

12. Switch the unit OFF.

8.1

Cleaning unit from outside

Wipe down unit externally with a cloth which has been

immersed in a suitable cleaning agent.

Danger of short circult through pane-

trating water !

Never spray down the unit with

high-pressure or high-pressure steam

cleaners.

Danger

First of all pull out mains plug from

socket.

Danger

Caution! Do not pump or spray into a

container with a small opening (bung-

hole)!

Refer to the safety regulations.

Danger

The container must be earthed in case of

coating materials which contain solvents.

Attention

Cleaning the unit (shutting down)

8.2

Suction filter

–

Screw off the filter (Fig. 7) from suction pipe.

–

Clean or replace the filter.

Carry out cleaning with a hard brush and an appropri-

ate cleaning agent.

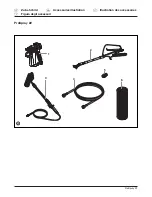

8.3 Cleaning Airless spray gun

–

Rinse Airless spray gun with an appropriate clean-

ing agent.

–

Clean tip thoroughly with appropriate cleaning

agent so that no coating material residue remains.

–

Thoroughly clean the outside of the Airless spray

gun.

Intake filter in Airless spray gun

Dismounting (Fig. 8)

1.

Pull protective guard (1) forward vigorously.

2.

Screw grip (2) out of the gun housing. Remove

intake filter (3).

3.

Intake filter congested or defective – replace.

Mounting

1.

Place intake filter (3) with the long cone into the gun

housing.

2.

Screw in grip (2) into the gun housing and tighten.

3.

Slot in protective guard (1).

W

arn

ing

:

ke

ep

cl

ea

r

of

tip

25

0 b

ar

ma

x.3

60

0 p

si

3

2

1

A clean suction filter always guarantees

maximum feed quantity, constant spraying

pressure and problem-free functioning

of the unit.

i