39

•

Fill water into receptacle.

When operating using the container suction system,

immerse suction hose into receptacle with water.

Turn on mortar spraying machine.

•

After a few seconds the cleaning ball will come out

of the spray lance.

•

Repeat cleaning procedure 3–4 times, depending on

the coating material used.

There is a further possibility for cleaning using the

cleaning adapter.

This cleaning adapter can be connected to a water hose

or tap with a claw coupling.

Place cleaning ball in the mortar hose.

Couple mortar hose to the cleaning adapter and rinse

through with water.

10.2

Cleaning device and changing pump jacket

Pump jacket disassembly

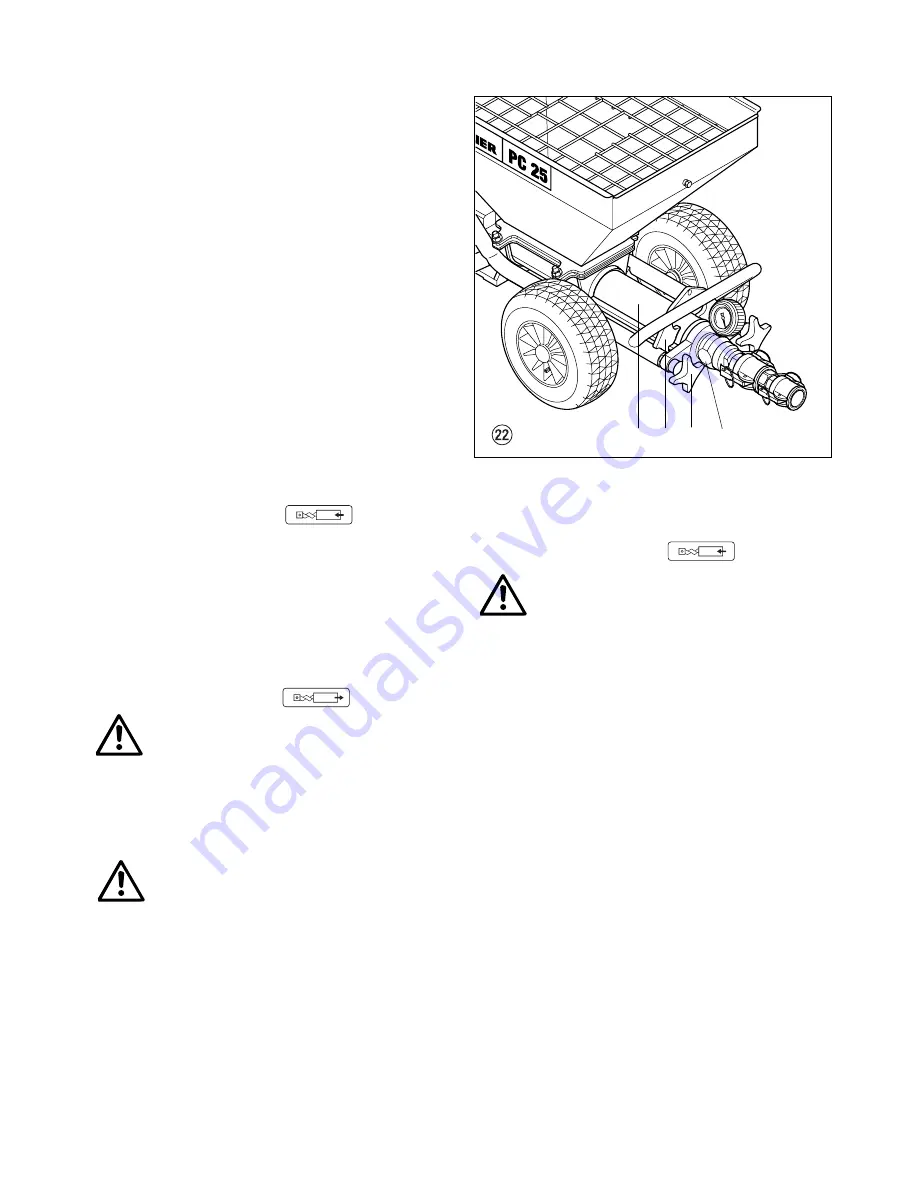

• Lubricate pump

Turn changeover switch to (backwards).

Spray pump antiseize or a little dishwashing liquid

into the outlet unit (2, fig. 22) or place a little

dishwashing liquid into the receptacle and pump

through the pump.

• Turn changeover switch to "0".

• Unscrew star grips (1, fig. 22).

• Remove outlet unit (2) towards the front.

• Set feed rate to "3".

• Turn changeover switch to (forwards).

Danger of crushing

• Pump jacket (3) will disconnect from pump screw.

• Set changeover switch to "0".

• Clean receptacle and receptacle lower section with a

water jet.

When operating using the container suction

system, turn off device using master switch.

Remove the mains plug from the socket and

ensure that it cannot be replaced

unintentionally.

• Unscrew and remove container connection from the

receptacle lower section.

• Clean receptacle lower section, container connection

and suction hose with a water jet and, if necessary,

using a suitable brush.

• Clean pump screw and pump jacket thoroughly with

water.

• Clean outlet unit (2) inside using a bottle brush.

• Keep threads for the star grips clean and grease.

Pump jacket assembly

Important:

Spray pump screw and pump jacket with

pump antiseize or wet with dishwashing

liquid.

• Turn changeover switch to (backwards).

Danger of crushing

• Place pump jacket (3) onto pump screw.

• Ensure that the ledge of the pump jacket (3) is

properly slid into the rectangular recess of the pump

trigger (4).

• Pump jacket pulls itself onto the pump screw.

• Set changeover switch to "0".

• Assemble outlet unit.

10.3 Cleaning spray lance

• Clean texture nozzle.

• Clean air holes in the texture nozzle with a cleaning

needle.

• Clean the inside of the spray lance with a bottle

brush

g

3

2

1

4

Содержание Plast Coat 25

Страница 1: ...Ow n e r s Ma n u a l...

Страница 10: ...Tabelle Teil 1 32 g...

Страница 11: ...Tabelle Teil 2 33 g...