Operating manual Powder Cup Gun PEM-X1 CG

7 Operation

Order number 2326960 | Edition 10/2022

27

7 OPERATION

7.1 TRAINING THE OPERATING PERSONNEL

– The operating personnel must be qualified to operate the entire system.

– The operating staff must be familiar with the potential risks associated with improper

behavior as well as the necessary protective devices and measures.

– Before work commences, the operating personnel must receive appropriate system

training.

7.2 TASKS

1. Ensure that:

4

regular safety checks are performed in accordance with Chapter Safety Checks

[

4

commissioning is carried out in accordance with chapter Assembly and

Commissioning [

21].

7.3 SWITCHING ON THE MANUAL POWDER SPRAY GUN

1. To put the control unit into operation, see corresponding operating manual.

2. Hold the manual powder spray gun in the spray booth.

3. Via the trigger lever of the manual powder spray gun, the high voltage and the coating

material supply are activated at the same time.

4. Adjust the powder cloud on a test piece.

7.4 OPTIMIZING THE POWDER CLOUD FOR COATING

1. Switch on high voltage generator and powder feed.

Note:

To minimize wear on the wearing parts, the total air volume should be below 5 Nm³/h.

The atomizing air should be set for the

ð

flat jet nozzle to 0.1 Nm³/h

ð

round jet nozzle to > 0.2 Nm³/h

2. Adjust the powder quantity and the powder speed on a test piece.

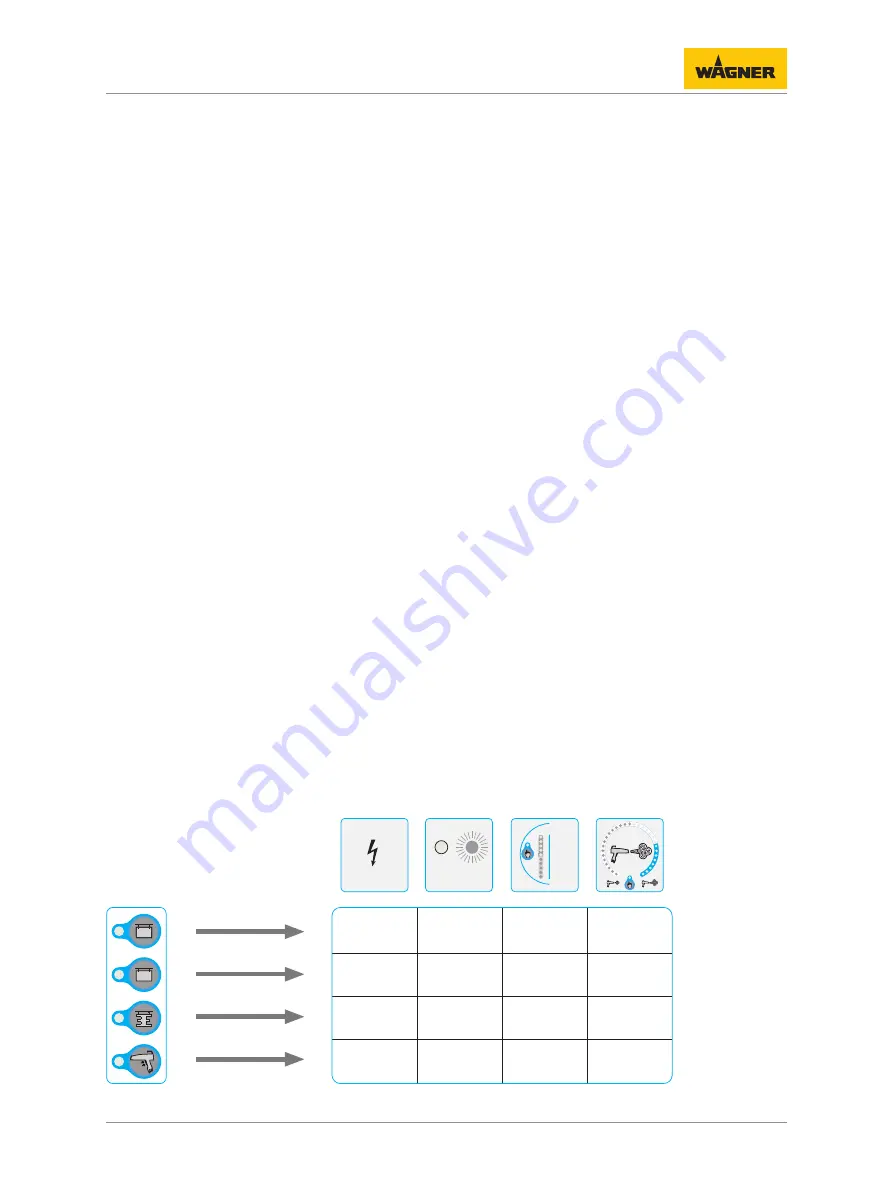

7.4.1 Settings Recommendation for Total Air Volume

2x

2x

Tribo Corona

Ø

12

10

11

9

8

m /h

2.0

3

5.5

4.5

3.5

2.5

0 %

100 %

10

20

30

40

50

60

70

80

90

[µA]

[Nm³/h]

[%]

[kV]

90

80

2.0

50

50

30

1.5

40

60

40

1.2

40

P_01828

82

20

1.8

30

Содержание PEM-X1 CG

Страница 2: ......

Страница 62: ...Operating manual Powder Cup Gun PEM X1 CG 14 Declaration of Conformity 62 Order number 2326960 Edition 10 2022...

Страница 63: ......