2 7

Control Pro 350 Extra Cart

GB

Problem

Cause

Remedy

The spray device

runs but does not

suck up any paint

when the selector

switch is set to the

PRIME position.

•

The unit will not prime properly or has lost

prime.

•

The paint bucket is empty or the suction tube

is not totally immersed in the paint.

•

The suction tube is clogged.

•

The suction tube is loose at the inlet valve.

•

The inlet valve is stuck.

•

The inlet valve is worn or damaged.

•

The PRIME/SPRAY valve is plugged

➞

Try to prime the unit again.

➞

Reill the bucket or immerse the suction tube in

paint.

➞

Clean the suction tube.

➞

Tighten it securely.

➞

Press the inlet valve pusher. If the problem is not

solved, clean the inlet valve.

➞

Replace

➞

Please contact Wagner Service

The sprayer draws

up paint but the

pressure drops

when the gun is

triggered.

•

The spray nozzle is worn.

•

The inlet ilter is clogged.

•

The spray nozzle is blocked (if itted)

•

The paint is too viscous or contaminated.

•

The inlet valve is worn or damaged.

➞

Replace the spray nozzle with a new nozzle.

➞

Clean the inlet ilter.

➞

Clean or replace the ilter.

➞

Thin or strain the paint.

➞

Replace

The spray gun leaks

•

Internal parts of the gun are worn or dirty.

➞

Please contact Wagner Service

The nozzle

assembly leaks

•

The nozzle was assembled incorrectly.

•

A seal is dirty.

➞

Check the tip assembly and assemble properly

➞

Clean the seal.

The spray gun will

not spray.

•

The spray nozzle is plugged.

•

The spray nozzle is blocked (if itted)

•

The spray tip is in the reverse position.

➞

Clean the spray nozzle and use the HEA ilter set.

➞

Clean or replace the ilter.

➞

Put the nozzle in the forward position.

The paint pattern is

tailing.

•

The paint is too viscous or contaminated.

•

The spray nozzle is plugged.

•

The spray nozzle is worn.

•

The spray nozzle is blocked (if itted)

•

The inlet ilter is clogged.

•

The inlet valve is worn or damaged.

➞

Thin or strain the paint.

➞

Clean the spray nozzle and use the HEA ilter set.

➞

Replace the spray nozzle with a new nozzle.

➞

Clean or replace the ilter.

➞

Clean the inlet ilter.

➞

Replace

Warning

If the supply cord of this appliance is damaged, it must only be

replaced by a repair shop appointed by the manufacturer, because

special purpose tools are required.

The wires in this mains lead are coloured in accordance with the

following code:

green/yellow = earth blue = neutral

brown = live

As the colours of the wires in the mains lead of this appliance may not

correspond with the coloured markings identiiying the terminals in

your plug, proceed as follows:

•

The wire which is coloured green and yellow must be connected

to the terminal in the plug which is marked with the letter E or by

the earth symbol or coloured green or green and yellow.

•

The wire which is coloured blue must be connected to the

terminal which is marked with the letter N or coloured black.

•

The wire which is coloured brown must be connected to the terminal which is marked with the letter L or coloured brown.

•

Should the moulded plug have to be replaced, never re-use the defective plug or attempt to plug it into a diferent 13 A socket.

This could result in an electric shock.

•

Should it be necessary to exchange the fuse in the plug only use fuses approved by ASTA in accordance with BS 1362. Only 13

Amp fuses may be used.

•

To ensure that the fuse and fuse carrier are correctly mounted please observe the provided markings or colour coding in the

plug.

•

After changing the fuse, always make sure that the fuse carrier is correctly inserted. With out the fuse carrier, it is not permissible

to use the plug.

•

The correct fuses and fuse carriers are available from your local electrical supplies stockist.

Содержание CONTROL PRO 350 EXTRA CART

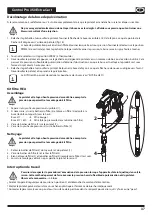

Страница 3: ...Control Pro 350 Extra Cart SPRAY PRIME A PRIME SPRAY B SPRAY PRIME SPRAY PRIME 0 OFF A B A B ...

Страница 4: ...Control Pro 350 Extra Cart 25 30 cm A B C 20 25cm 20 25 cm 20 25 cm D A B ...

Страница 138: ...132 Control Pro 350 Extra Cart ...

Страница 139: ...133 Control Pro 350 Extra Cart ...