EN

19

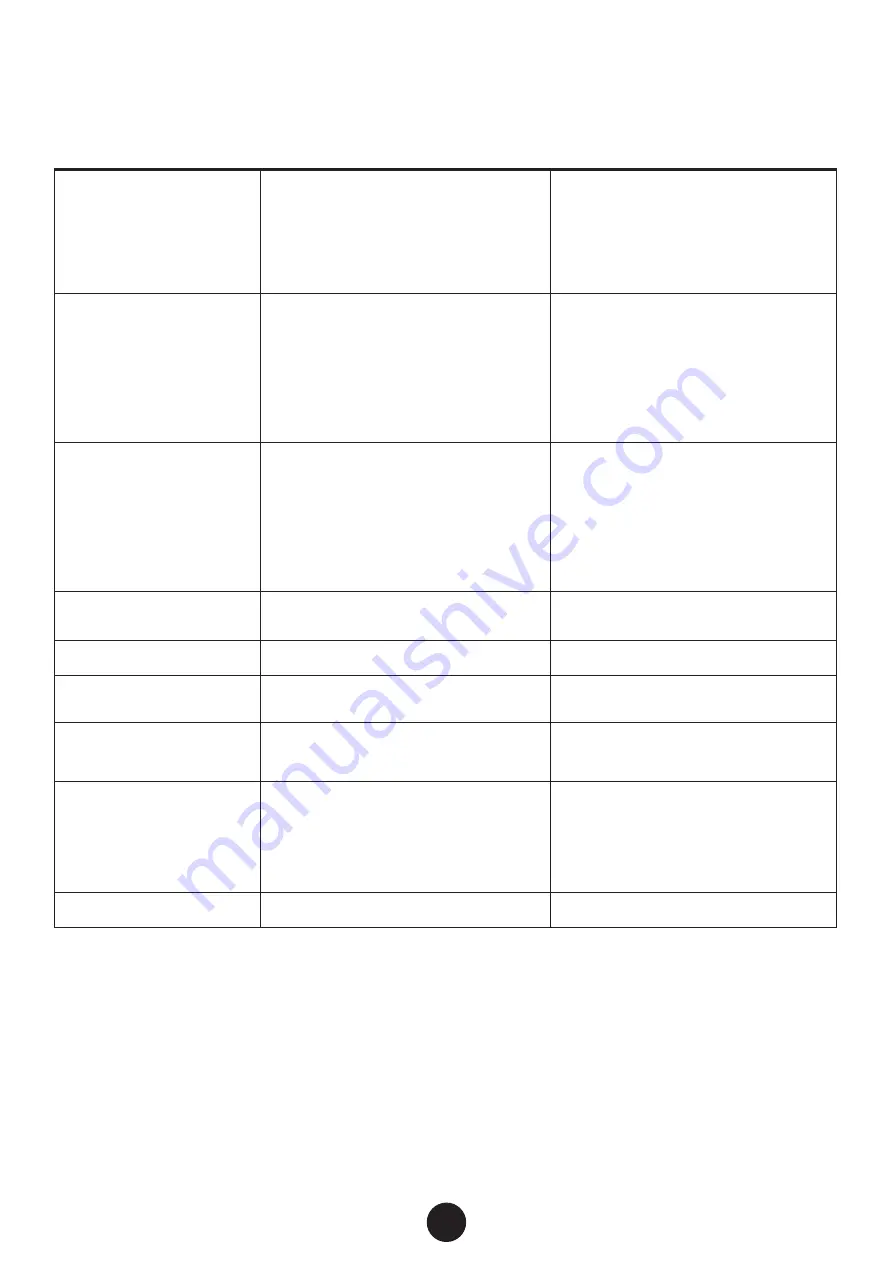

TROUBLESHOOTING

PROBLEM

CAUSE

SOLUTION

A. The sprayer does not turn on.

1. The sprayer is not plugged in.

2. The sprayer is turned OFF (0).

3. The sprayer shuts off while under pressure.

4. No power is coming from power outlet.

5. The extension cord is damaged or is not the

proper gauge or length.

6. There is a problem with sprayer motor.

7. Spray tip clogged.

1. Plug the sprayer in.

2. Switch the sprayer ON (l).

3. Motor will cycle ON and OFF while spraying to

regulate pressure. This is normal.

4. Reset circuit breaker or find another outlet.

5. Refer to General Information.

6. Call Technical Service (1-800-328-8251).

7. Refer to Clear the Spray Tip.

B. The sprayer starts but does not

draw material when the PRIME/

SPRAY knob is set to PRIME

1. The inlet valve is stuck from old material.

2. There is no suction at the inlet valve.

3. The inlet filter is clogged.

4. The outlet valve is stuck or contains debris.

5. The inlet valve or outlet valve is worn or

damaged.

6. The PRIME/SPRAY valve is plugged.

1. Push inlet filter tab to release. If still stuck refer

to Cleaning the Inlet Valve.

2. Remove inlet filter and check suction by placing

finger on inlet valve. If no suction, refer to

Cleaning the Inlet Valve.

3. Refer to Clean the Inlet filter or replace the inlet

filter.

4. Refer to Cleaning the Outlet Valve.

5. Replace the inlet valve or outlet valve.

6. Call Technical Service (1-800-328-8251).

C. The sprayer draws material but

the pressure drops when the gun

is triggered (bad spray pattern or

no spray pattern)

1. The spray tip is worn.

2. The inlet filter is clogged.

3. The spray tip is plugged.

4. The material is too heavy or thick.

5. The material is too coarse.

6. The outlet valve assembly is damaged or worn.

7. Spray hose is too long.

1. Replace spray tip with a new one.

2. Refer to Clean the Inlet filter, or replace with a

new inlet filter.

3. Refer to Clear the Spray Tip or replace with a

new spray tip.

4. Thin the material.

5. Strain the material or purchase the accessory

filter (see Accessories, page 58).

6. Replace the outlet valve.

7. Remove any extra hose length that has been

added.

D. The PRIME/SPRAY knob is set to

SPRAY and there is flow through

the material return tube

1. The PRIME/SPRAY valve is dirty or worn.

1. Call Technical Service (1-800-328-8251).

E. The spray gun leaks

1. Internal parts of spray gun are worn or dirty.

1. Call Technical Service (1-800-328-8251).

F. The spray tip assembly leaks

1. The tip guard nut is loose.

2. Tip guard was assembled incorrectly.

3. Tip seal is worn

1. Tighten tip guard nut.

2. Remove and assemble correctly.

3. Replace tip seal

G. The spray gun will not spray

1. The spray tip plugged.

2. The spray tip is in wrong position.

3. PRIME/SPRAY knob not set on SPRAY.

4. Accessory filter is dirty or plugged.

1. Refer to Clear the Spray Tip .

2. Rotate spray tip to SPRAY position.

3. Turn PRIME/SPRAY knob to SPRAY.

4. Clean or replace.

H. The spray pattern is poor (tailing) 1. The spray tip is plugged.

2. The inlet filter is clogged.

3. The spray tip is worn.

4. The material is too heavy or thick.

5. Spray hose is too long.

2. Refer to Clear the Spray Tip

3. Refer to Clean the Inlet filter or replace with a

new inlet filter.

4. Replace the spray tip.

5. Thin material per manufacturer’s

recommendations.

5. Remove any extra hose length that has been

added.

I. The spray tip will not turn

1. High pressure has locked the spray tip in place.

1. Refer to Clear the Spray Tip.