© 1995 Wagner Spray Tech

14

All rights reserved.

that it is parallel to the gun body.

14. Turn the motor switch to OFF.

Preparing the sprayer for long term storage

1. Remove the tip assembly and raise the suction set

above the cleaning solution.

2. Turn the motor to ON.

3. Turn the PRIME/SPRAY knob to SPRAY (

).

4. Turn the pressure control knob clockwise to 1/2

power and allow the suction tube to run dry.

5. Remove the large suction tube from the inlet valve

and point the gun into the cleaning bucket.

6. Unlock the gun and trigger it into the cleaning

bucket until the hose is pumped dry.

7. Lock the gun and turn the pressure control knob

counterclockwise to its lowest setting.

8. Turn the PRIME/SPRAY knob to PRIME ( ).

9. Lay the sprayer back on its handle so that the inlet

valve is facing upward.

10. Clean the threads of the inlet valve with a damp

cloth.

11. Fill the inlet valve with a light household oil. Slowly

increase the pressure to distribute the oil through

the pump.

12. Turn the PRIME/SPRAY knob to SPRAY (

) to

distribute the oil.

13. Replace the large suction tube onto the inlet valve.

NOTE: Proper cleaning and oiling of the pump after

use are the most important steps you can

take to insure proper operation after storage.

14. Turn the pressure control knob counterclockwise to

its lowest setting.

15. Turn the PRIME/SPRAY knob to PRIME ( ).

16. Trigger the gun to remove any pressure which may

still be in the hose.

17. Lock the gun by turning the gun safety switch so

that it is parallel to the gun body.

18. Turn the motor switch to OFF.

19. Remove and clean the suction set filter in clean

water or the appropriate solvent. Use a soft brush.

Return the suction set filter to its original position.

20. Wipe the entire unit, hose and gun with a damp

cloth to remove accumulated paint.

Follow these procedures when encountering problems

indicated in the troubleshooting section.

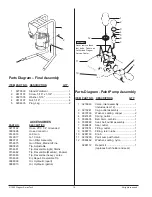

Removing and cleaning the inlet valves

1. Be certain that the sprayer is off.

2. Remove the inlet valve assembly using a 27 millime-

ter socket or box end wrench.

3. Test movement of the valve by pushing on it from

the open end of the valve housing with a screw-

driver or the eraser end of a pencil. It should move

about 1/16 of an inch. If it does not move, it should

be cleaned or replaced.

Содержание 0278712C

Страница 16: ...1995 Wagner Spray Tech 16 All rights reserved...