12 |

P a g e

DOC-MN-007-03 VCCM600 User Manual

Vox Power Limited | Unit 2, Red Cow Interchange Estate, Ballymount, Dublin 22, D22 Y8H2, Ireland | T +353 1 4591161 | www.vox-power.com

Specifying the VCCM600 product for convection or forced air cooling

To specify a VCCM600 series product for an end application, the required output power, minimum input line voltage, maximum ambient, mounting orientation

and air flow rate (if applicable) should be determined. Check the requirements against the closest characteristic plot from the tables above to ensure ratings can

be achieved. Be conservative when specifying the product as convection and forced air cooling can be highly dependent on the end application enclosure and

power supply mounting. The estimated performance must be verified in the end application and temperatures may exceed predicted levels. It is also important

to note that ambient temperature refers to the ambient temperature immediately surrounding the PSU. If the PSU is mounted within an enclosure the enclosure

ambient temperature is likely to be higher than the external air ambient temperature.

Evaluating the VCCM600 product in the end application

To ensure the product is operating within its ratings in the end application the following procedure should be performed during the design stage.

1.

Install a thermocouple in position TS1 of the product. (See Mechanical dimensions and mounting for details.) The thermocouple wire should exit on

the top side between slots 2 and 3. The bottom side should be flush for heatsink mounting if necessary. Glue should be used to hold the

thermocouple in place.

2.

Setup the application in worst case conditions, considering Input line voltage, Output power, ambient temperature, airflow and cooling restrictions.

3.

Power the system and monitor the baseplate temperature until it reaches steady state.

4.

Ensure that under worst case conditions, the baseplate temperature cannot exceed the rated temperature as outlined in the power ratings section of

this manual.

If a cover is placed over the primary components, then the following component temperatures must also be measured to ensure they are below the maximum

specified temperatures.

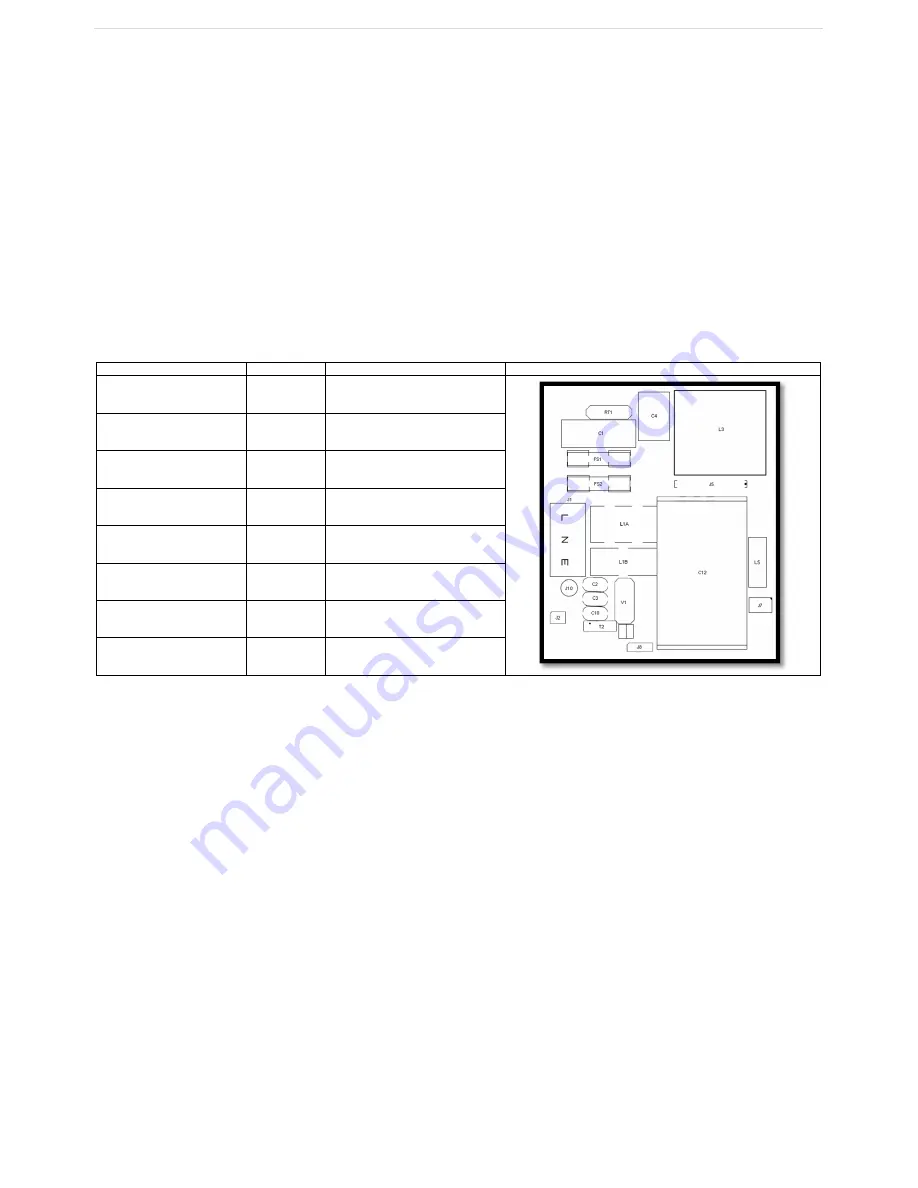

Description

Reference

Maximum allowed temperature

Drawing

Fuse

FS1, FS2

125

°

C

Electrolytic capacitors

C12

105

°

C

Inductors

L1, L2, L3, L5

130

°

C

Other capacitors

C1, C4

110

°

C

If excessive temperatures are measured during this evaluation, then one or more of the following remedies may improve thermal performance.

Increase heatsink size

Increase airflow rate

Improve air intake & outlet

Reduce power requirement

Using the internal temperature sensor to control external application cooling

An internal temperature sensor T

SNS

is available on J3 pin 9 (See page 14 for details). The output voltage of this sensor gives a measurement of the internal

transformer temperature

and can be used to control external cooling systems or to provide a warning of impending over temperature protection.

The internal temperature (T

SNS

) should never exceed 120⁰C (2.74V), however, system reliability will be maximised if the PSU temperature is maintained as low as

possible in any given application.