23

Venting the fuel system

Venting of the fuel system must be carried out prior to the first start of the engine and

after work has been carried out on the fuel system, when the fuel tank has been run

empty or if the engine has been out of operation for some time.

Venting is carried out as follows: (Regarding location, See Engine Component Guide).

1

Open venting screw on fuel filter about 4 turns. Be careful not to

spill fuel. Use rags around the vent opening.

2

Pump up the fuel by using the hand primer until fuel, free from air

bubbles flows out. Close venting screw. If the pump action is poor,

turn the engine so that the cam driving the pump changes position.

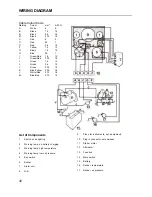

3

If the injection pump has been removed, or when first starting a

new engine, the injection pump must be vented. BOSCH Fuel

Injection pump: Operate the handprimer for approximately half a

minute. The injection pump is then automatically vented.

CAV Fuel Injection pump has two air venting screws, see picture.

Vent No 1 and then No 2. Operate handprimer until fuel free from

air bubbles flows out at screw No 1. Tighten screw No 1. Put

throttle control lever in position full speed and turn engine using

starter motor until fuel free from air bubbles flows out of screw No

2. Tighten screw No.2.

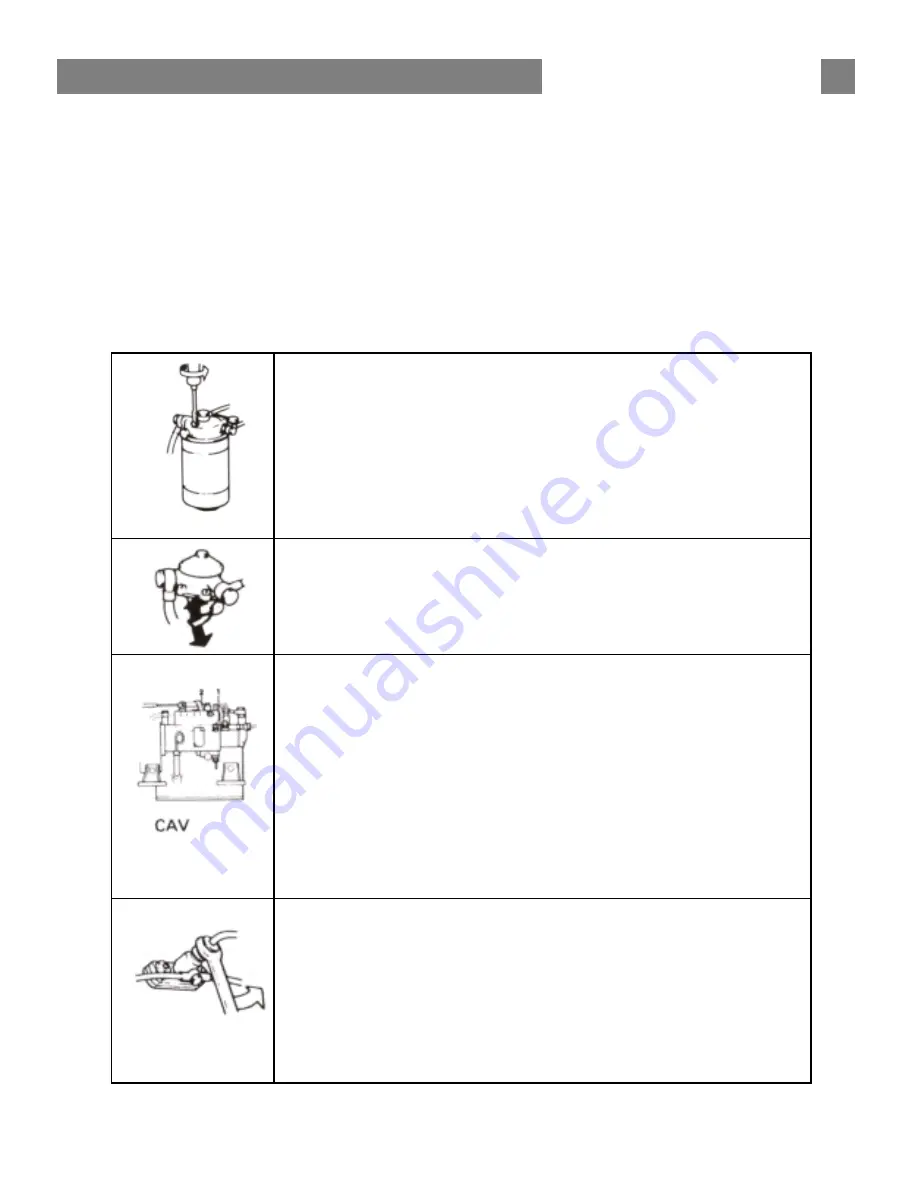

4

Loosen the injector’s delivery pipe nut, push in the stop control and

put the throttle lever in full speed position. Turn the engine using

the starter motor until fuel flows out of the delivery pipes. Be

careful not to spill fuel! Use rags around the venting location.

Tighten the delivery pipe nuts and start the engine.

CHECKS AND SERVICE