Supplied By www.heating spares.co Tel. 0161 620 6677

-7-

7. Open and close a hot tap to ensure continuity of supply

8.

Turn on electrical supply to the immersion heaters.

Hot water discharge from tundish

This indicates a malfunction of a thermal cut-out, operating thermostat or the combined temperature

and pressure relief valve. Turn off the electrical supply to the immersion heater and also isolate an

indirect unit from the boiler. Contact the installer or competent engineer.

INSTALLATION AND SERVICING INSTRUCTIONS

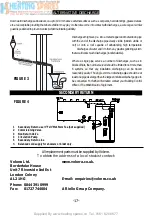

Cold water inlet control (Multibloc) See Page 2/3 Items 3 - 4

This combination consists of a pressure reducing valve with integral strainer, check valve and

expansion valve with stainless steel seat. The pressure settings are set and locked in the factory

and are shown on the top of each valve. For optimum performance the following installation

instructions should be complied with.

Installation

1. Cold water supply to be 22 mm nominal size.

2. Flush supply pipework before connection to remove all flux and debris prior to fitting the inlet

controls. Failure to do this may result in irreparable damage to the controls and will invalidate

the warranty.

3. The "MULTIBLOC" can be fitted in any orientation to suit the installation as long as it is fitted in

the correct flow direction. Check the flow arrows on the side of the body.

4. The expansion valve should be either horizontal or upright - if fitted inverted, debris may be

deposited on the seat and cause fouling of the seat when the valve operates. Check direction of

flow arrows.

5. The black plastic plugs in the body are pressure gauge connections to enable pressure

monitoring to be carried out, should the system develop a fault. It is recommended that these be

accessible (the pressure reducing valve has two - only one need be accessible).

6. Expansion relief drain pipework must be connected to a safe visible discharge point via a

tundish and the pipework must have a continuous fall.

7. The pressure reducing valve has two outlets, the second one is for a balanced cold water

supply, to a shower or a bidet (over rim type only, ascending spray type requires type

AA,AB or AD air gap)

(Major shower manufacturers advise fitting a mini expansion vessel in

the balanced cold supply pipework to accomodate thermal expansion and prevent tightening of

shower controls)

Using the balanced cold connection to feed bath taps can reduce the

flow available to the unvented cylinder. The balanced cold supply is blanked off.

NOTE: If the unit has been commissioned and is to be unused for more than 8 weeks it is

advisable to turn off the cold supply and draw off approximately 5 litre of water through a hot

tap. NB The cold supply must be opened prior to use.

The Benchmark Log Book enclosed with the cylinder should be completed after

commissioning the system and handed to the customer for future reference.