6

7

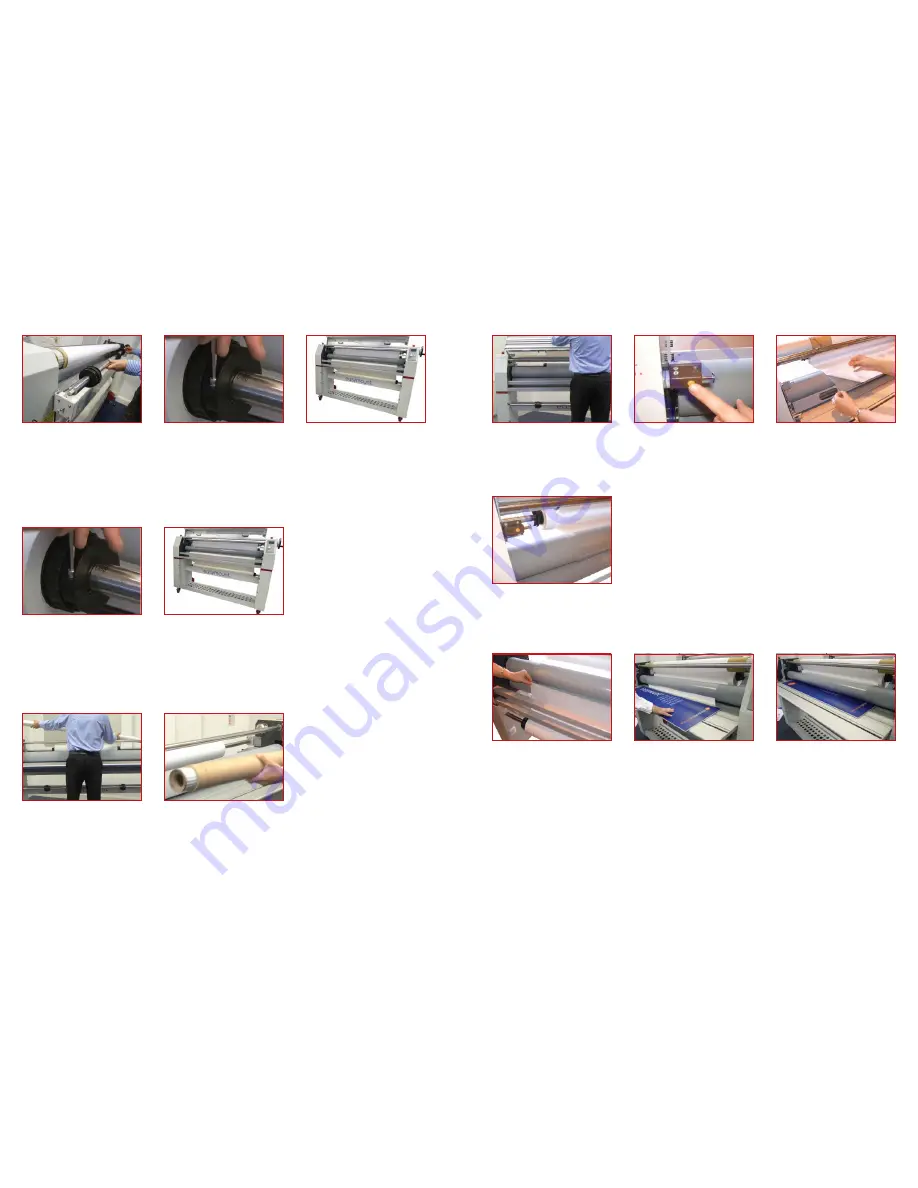

Take up mandrel (Release Liner)

1. Remove the top mandrel from the

mandrel support brackets

5. Re-load the mandrel on to the brackets

with the fi lm feeding from the bottom of

the mandrel, if the fi lm is wound with the

fi lm on the outside, or off the top of the

roll if the fi lm is wound on the inside.

2. Loosen the two fastening screws on

one of the mandrel core grips, slide off

one side.

3. Slide on the fi lm positioning it centrally

on the mandrel and re-fi x the core grips.

4. Release the tension on the fi lm by

turning the ‘friction adjustment sleeve’

Pressure sensitive fi lm (loaded on the top mandrel)

Installation of Laminating Films

1. Remove the mandrel from the mandrel

support brackets

2. Loosen the two fastening screws on

the mandrel core grips, slide off one side

3. Slide on the liner paper/mount fi lm

and position centrally to match the top

4. Re-load the mandrel into the brackets

1. The take up mandrel is held in place

with a sprung loaded bracket: to remove

push towards the spring and lift upwards

2. Slide an empty cardboard core onto

the take up mandrel and replace

Vinyl/Liner paper/Mount fi lm (loaded on the bottom mandrel)

1. Lift the feed tray to the upright

position and lock securely. Following the

loading diagram on the left cabinet of

the machine, pull the fi lm off the bottom

of the mandrel and towards the front of

the machine, going over the top of the

upper roller

2. Peel back the liner paper from the

fi lm, exposing the adhesive side of the

laminate and stick release liner to take up

mandrel using double sided tape

Pressure sensitive fi lm (loaded on the top mandrel)

Film Loading

3. Drape the fi lm over the upper roller

and stick the liner paper to the take up

mandrel using double sided tape

1. Following the loading diagram feed

the paper up over the lower roller

and stick it to the adhesive side of the

pressure sensitive fi lm

5. Press the drive button and feed

through. PLEASE NOTE When the board

is through the rollers the pressure handle

will need to be adjusted to compensate

for thickness

2. Using the pressure handle raise the

upper roller

3. Using a piece of stiff card or mount

board push the overlapped fi lms into the

nip of the roller

4. Using the roller pressure handle lower

the upper roller so it clamps the material

Liner Paper (Load on the Bottom Mandrel)

(Safety guard lock)