6

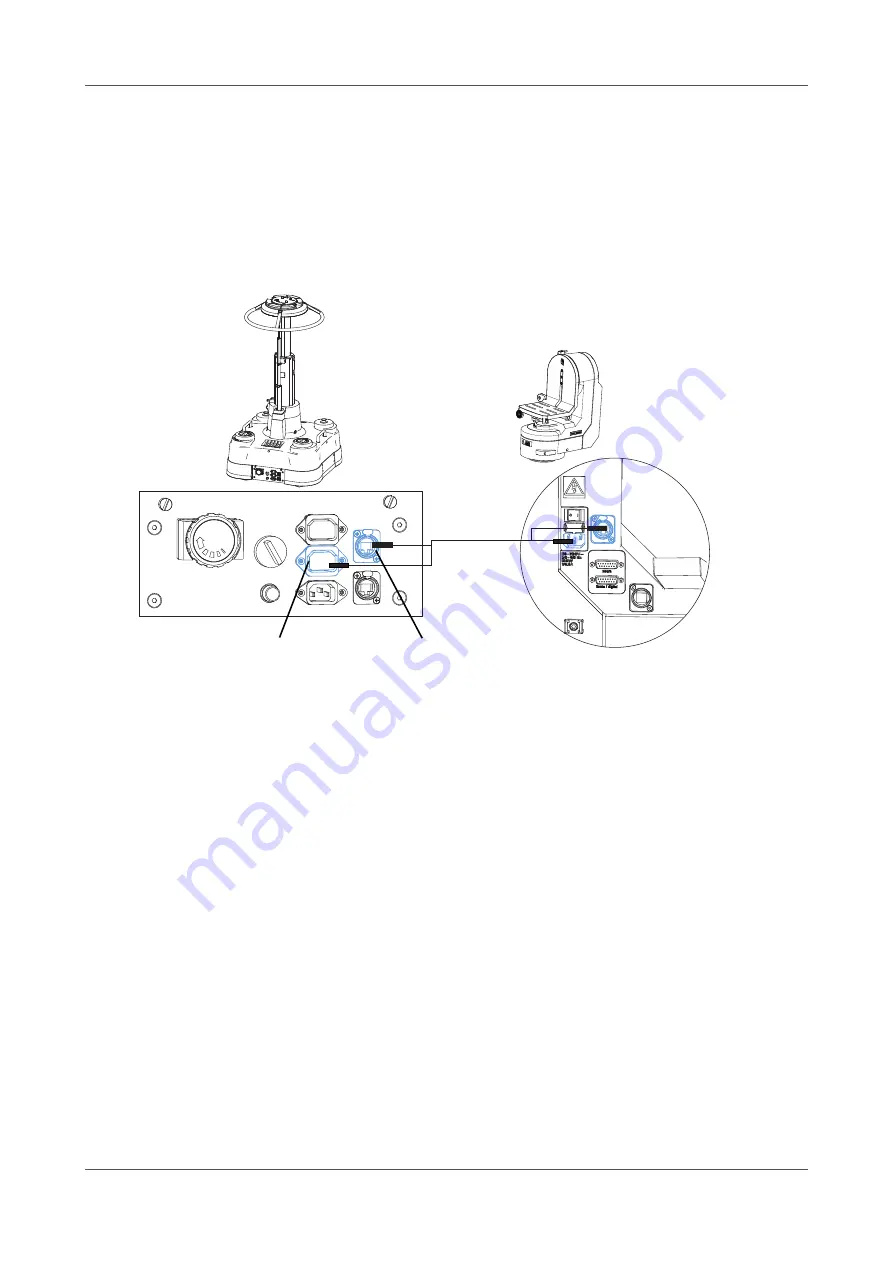

There are two EPL ports on the Pedestal control panel. One port is used to connect the Pedestal to the Control

Panel via an EPL Node and the other port can be used to provide the EPL data communications to the Head.

Although the Head and EPL Node can be connected to either of the ports, it is recommended that the Head is

connected to the upper port, with the EPL Node connected to the lower port, to prevent the Head

Communication cable from being dislodged by the Studio Floor cable as the pedestal moves around the studio.

The power and EPL connections from the Fusion Pedestal (FP-145/FP-188) to the Head are shown in

Connecting the Head to a Fusion Height Drive

When the Head is mounted onto a manual only pedestal, a Fusion Height Drive (FBH-175) can be installed to

remotely operate the height of the pedestal from a Vinten Radamec Control Panel.

The Height Drive has two power output sockets and a single power inlet socket that is connected to the studio

supply. The

Head Power Output

socket is used to supply power to the Head. Note that the

Head Power

Output

socket is controlled by the Height Drive and therefore it is switched, fused and isolated on activation of

the emergency stop button on the Height Drive. Each power connector on the Height Drive is fitted with a

connector retaining clip to prevent the cable becoming dislodged causing accidental loss of power. Always

ensure that the retaining clip is fastened.

EPL connection to the Head is supplied by the

EPL Out

port on the Height Drive. The

EPL In

port connects to

the Vinten Radamec Control Panel via the EPL Node. The Height Drive is supplied with a Head Communication

cable that can be used to connect the Height Drive to the Head.

The power and EPL connections from the Fusion Height Drive to the Head are shown in

Figure 4 Fusion Pedestal to Head Power & EPL Connections

Head

Communication

cable

Head Power

Output socket

Head EPL port

Содержание RADAMEC Fusion FH-100

Страница 35: ...22 ...