35

REF. NO.

PART NO.

DESCRIPTION

Q'TY

CODE

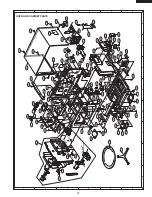

OVEN PARTS

4- 1

FOVN-A314WRY0 Oven cavity assembly (Not Replaceable)

1

4- 2

FROLPA072WRK0 Turntable support

1

4- 3

NTNT-A128WRHZ Turntable tray

1

4- 4

DHET-A138WRKZ Heater unit assembly

1

4- 5

LANGKA723WRP0 Glass mounting plate

1

4- 6

PCUSUA167WRP0 Cushion

2

4- 7

PCUSUA424WRP0 Cushion

1

4- 8

FDUC-A323WRW0 Steam duct assembly

1

AY

4- 9

MCAMPA030WRF0 Damper cam

1

AC

4-10

NSFTTA114WRE0 Damper shaft

1

AB

4-11

FFTA-A034WRK0 Damper door ass’y

1

AM

4-12

PDUC-A269WRW0 Damper duct

1

AK

4-13

PCUSGA398WRP0 Cushion

1

AC

4-14

NCPL-A058WRFZ Turntable coupling

1

AE

4-15

PCOVPA301WRE0 Waveguide cover

1

AE

4-16

PCUSUA197WRP0 Cushion

2

AD

4-17

PGLSPA455WRE0 Light glass

1

AD

4-18

PFPF-A139WRE0 Thermal protection sheet (Right)

1

AF

4-19

PREFHA053WRW0 Thermal protection plate (Right)

1

AP

4-20

PSKR-A153WRW0 Air guide (Bottom)

1

AK

4-21

PSKR-A323WRW0 Air guide (Right)

1

AF

4-22

NFANJA020WRE0 Fan blade

1

AE

4-23

PDUC-A270WRF0 Cooling fan duct

1

AL

4-24

LANGFA089WRW0 Chassis support

1

AE

4-25

MHNG-A520WRMZ Oven hinge (Upper)

1

AE

4-26

LANGQA474WRP0 Noise unit angle

1

AG

4-27

PCUSUA196WRP0 Cushion

2

AD

4-28

PCUSUA425WRP0 Damper duct cushion

1

AG

4-29

PCUSGA353WRP0 Cushion

1

AH

4-30

PSKR-A171WRW0 Magnetron air guide

1

AE

4-31

PFPF-A064WRE0 Thermal protection sheet

1

AF

4-32

PCOVPA304WRP0 Thermo cover

1

AF

DOOR PARTS

5

FCOV-B425/KIT Door frame assembly (VMOC206BK)

1

BT

5

FCOV-B426/KIT Door frame assembly (VMOC206WH)

1

BT

5

FCOV-B411/KIT Door frame assembly (VMOC206SS)

1

BT

5

FCOV-B428/KIT Door frame assembly (VMOC206BT)

1

BT

5

FCOV-B429/KIT Door frame assembly (VMOC206SG)

1

BT

5

FCOV-B430/KIT Door frame assembly (VMOC206GG)

1

BT

5

FCOV-B431/KIT Door frame assembly (VMOC206BU)

1

BT

5

FCOV-B432/KIT Door frame assembly (VMOC206LE)

1

BT

5

FCOV-B433/KIT Door frame assembly (VMOC206MJ)

1

BT

5

FCOV-B438/KIT Door frame assembly (VMOC206MS)

1

BT

5

FCOV-B435/KIT Door frame assembly (VMOC206VB)

1

BT

5

FCOV-B436/KIT Door frame assembly (VMOC206CB)

1

BT

5

FCOV-B439/KIT Door frame assembly (VMOC206TP)

1

BT

5

FCOV-B441/KIT Door frame assembly (VMOC206OG)

1

BT

5

FCOV-B440/KIT Door frame assembly (VMOC206CW)

1

BT

5

FCOV-B442/KIT Door frame assembly (VMOC206GM)

1

BT

5

FCOV-B443/KIT Door frame assembly (VMOC206SA)

1

BT

5

FCOV-B444/KIT Door frame assembly (VMOC206SE)

1

BT

5

FCOV-B445/KIT Door frame assembly (VMOC206IB)

1

BT

5

FCOV-B446/KIT Door frame assembly (VMOC206PM)

1

BT

5

FCOV-B447/KIT Door frame assembly (VMOC206RR)

1

BT

5

FCOV-B448/KIT Door frame assembly (VMOC206PM)

1

BT

5

FCOV-B449/KIT Door frame assembly (VMOC206PL)

1

BT

5

FCOV-B450/KIT Door frame assembly (VMOC206CH)

1

BT

5- 1

DDORFA820WRY0 Door panel

1

BD

5- 2

GCOVHA155WRF0 Choke cover

1

AP

5- 3

LANGKA851WRT0 Latch angle

1

AF

5- 4

LSTPPA244WRFZ Latch head

1

AH

5- 5

MSPRTA192WRE0 Latch head spring

1

AA

5- 6

LANGKA918WRW0 Thermal plate U

1

AA

5- 7

LANGKA919WRW0 Thermal plate R

1

AA

5- 8

XCPS740P08000 Screw; 4mm x 8mm

6

AA

5- 9

XEPS730P08000 Screw; 3mm x 8mm

12

5-10

PCUSGA424WRP0 Cushion

1

5-11

LX-CZB019MRE0 Screw

3

Содержание VMOC206SS

Страница 3: ...3 Notes...