77

5608 741 - 04

Vitodens Rigid and Flex Venting Systems Installation

General Information

Exhaust Vent Requirements

The Vitodens 100-W, 200-W and 222-F boilers must be

located in such a way that the vent length is as short as

possible and that the vent can be routed as directly (and

with as few bends) as possible.

See pages 83 and 84 for maximum vent lengths.

All products of combustion must be safely vented to the

outdoors.

The Vitodens boiler is not approved for common-venting

applications. Do not common-vent with any other

appliance. The Vitodens boiler vents under positive

pressure and is a Category IV boiler.

Viessmann recommends that the entire vent system be

checked by a licensed professional heating contractor at

least once each year following initial installation.

Do not install vent pipe in a way that flue gases flow

downwards. The direction of flue gas flow must be

vertically upwards or horizontal with an upward slope.

Ensure there is no flue gas leakage into the area in which

the boiler is installed.

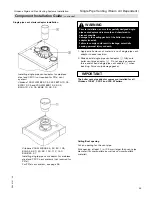

Check proper location of gaskets in rigid PP(s) pipe collars.

(Only use supplied parts with the polypropylene venting

system).

Apply water to lubricate the joint ends of the vent pipe

collar and if used, the air intake pipe collar.

Slide pipes into each other with a gentle twisting motion.

Check joints for leaks with the gas supply turned off and

the fan running. Use a soapy solution to check for vent

leaks.

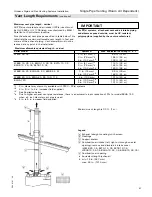

Condensate must drain from the flue pipe to the boiler.

Ensure a suitable gradient of at least 3º [approx. 2 in.

per 3.3 ft. (50 mm per 1 m)].

No condensate trap is required in the vent pipe system.

If exhaust vent pipe system passes through an unheated

space, such as an attic, it must be insulated. The

insulation must have an R value sufficient to prevent

freezing of the condensate. Armaflex insulation with

b

in. thickness and higher can be used.

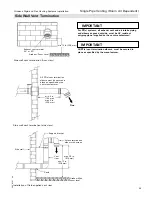

The connection between the boiler and the base of the

flexible pipe is made with rigid vent components (flexible

pipe cannot be run directly to the boiler).

The flexible pipe can only be used in vertical installations.

Direct venting (two-pipe system) or single pipe (room

air independent) is acceptable (refer to page 86 for

combustion air requirements for room air dependent

installations.

For direct venting applications the air intake pipe can be

installed through the sidewall or vertical through the roof.

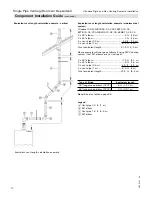

Any increaser used in the exhaust vent/air intake pipe

must be installed in the vertical position.

The remaining space surrounding a chimney liner, gas

vent, or special gas vent or plastic piping installed within

a masonry, metal or factory-built flue shall not be used

to supply combustion air (a separate combustion air pipe

routed back to the boiler can be used in the remaining

space if required).

WARNING

Different manufacturers offer a number of different joint

systems and adhesives. Do not mix pipes, fittings and/

or joining methods from different manufacturers. Failure

to comply could result in leakage, potentially causing

personal injury or death.

WARNING

Failure to ensure that all flue gases have been safely

vented to the outdoors can cause property damage,

severe personal injury, or loss of life. Flue gases may

contain deadly carbon monoxide.

Vent system suppliers

Use special venting system (UL/ULC listed for Category

IV) for exhaust vent material of the Vitodens boilers.

Contact on of the following suppliers to order parts.

All manufacturers deliver PP(s) rigid and flexible vents

the required sizes.

2 in. (60 mm)

2 in. (60 mm)

3 in. (80 mm)

3 in. (80 mm)

4 in. (100 mm)

4.3 in. (110 mm)

M&G / Duravent

www.duravent.com

Centrotherm InnoFlue

www.centrotherm.us.com

PolyFlue - Selkirk

www.polyflue.com

ECCO Manufacturing

www.eccomfg.com

Z-FLEX US Inc.

NovaFlex Group

www.novaflex.com