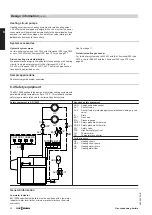

4.1 Product description

Gas condensing boiler with MatriX cylinder burner for natural gas E

and LL, for open or balanced flue operation

With two return connectors

For operation with a modulating boiler water temperature

Permissible operating temperature up to 95 °C

Permissible safety temperature up to 110 °C

Permissible operating pressure 5.5 bar (0.55 MPa)

■ CE designation: CE-0085AQ0257 in accordance with the Gas Appli-

ances Directive.

■ Boiler categories: B

23

, B

23P

, C

33

, C

43

, C

53

, C

63

, C

83

, C

93

■ Condensing Unit with MatriX cylinder burner as two-boiler system

up to 1260 kW.

■ Standard seasonal efficiency [to DIN]: up to

98 % (H

s

) [gross cv] / 109 % (H

i

) [net cv].

■ The stainless steel, corrosion-resistant Inox-Crossal heat exchanger

ensures high operational reliability and a long service life.

■ Inox-Crossal heat exchanger for highly effective heat transfer and

high condensation rate.

■ Self-cleaning effect through smooth stainless steel surface.

■ MatriX cylinder burner for particularly quiet and environmentally

responsible operation with a modulating range of 33 to 100 %.

■ Either open flue or balanced flue operation.

■ Cascade with pre-assembled accessories on the hydraulic and flue

gas side.

■ Hydraulically straightforward connection, no minimum flow rate, no

low loss header necessary, particularly low pressure drop on the

water side.

■ Easy to use Vitotronic control unit with plain text and graphic display.

4.2 Operating conditions

Note

For water quality requirements, see page 48.

Requirements

1. Heating water flow rate

None

2. Boiler return temperature (minimum value)

None

3. Low-end boiler water temperature

None

4. Lower boiler water temperature with frost protection

10 °C – ensured through the Viessmann control unit

5. Two-stage burner operation

None

6. Modulating burner operation

None

7. Reduced mode

None – total reduction is possible

8. Weekend setback

None – total reduction is possible

Vitocrossal 300, type CT3U, 400 to 630 kW

8

VIESMANN

Gas condensing boilers

4

5822 449 GB