CHECKING AND ADJUSTING

THE TOOL PRIOR TO GROOVING

Every Victaulic roll grooving tool is checked,

adjusted, and tested at the factory prior to

shipment. However, before attempting to operate

the tool, the following checks and adjustments

should be made to ensure proper tool operation.

WARNING

• Always turn off the main power supply

to the tool before making any tool

adjustments.

Failure to follow this instruction could result

in serious personal injury.

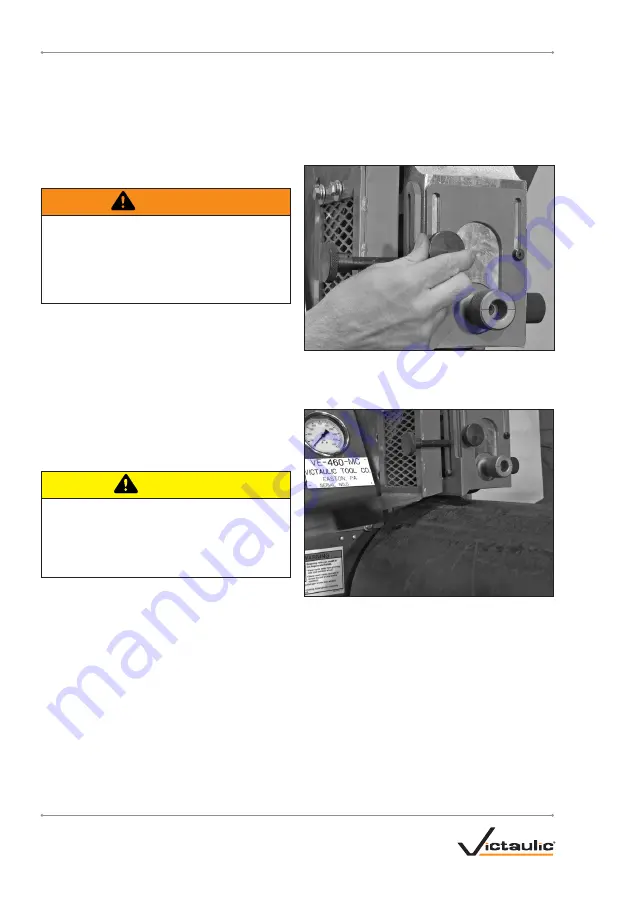

GROOVING ROLLS

Make sure the proper roll set is installed on the

tool for the pipe/tubing size and material that will

be grooved. Roll sets are marked with the pipe

size, part number, and they are color coded for

the pipe material. Refer to the applicable “Tool

Rating and Roll Selection” section. If the proper

rolls are not installed on the tool, refer to the

“Roll Changing” section.

CAUTION

• Make sure the lower-roll retaining bolt is

tight.

A loose lower-roll retaining bolt could cause

damage to the tool and rolls.

ADJUSTING THE ROLL GUARDS

The VE460 tool features a

“SET GUARD”

control switch setting. With the correct pipe

size and schedule inserted in the tool, the

“SET

GUARD”

setting allows the operator to complete

the necessary guard adjustments.

1.

Loosen the knob on the front of the roll

guards to raise the plate to its highest

position. Tighten the knob.

2. Insert a length of pipe that is the correct

size and schedule over the lower roll. Make

sure the pipe end contacts the lower-

roll backstop flange. The pipe must rest

directly on top of the roll and must not be

skewed to one side or the other.

TM-VE460_23

TM-VE460

OPERATING AND MAINTENANCE INSTRUCTIONS MANUAL

www.victaulic.com

VICTAULIC IS A REGISTERED TRADEMARK OF VICTAULIC COMPANY.

REV_A