12

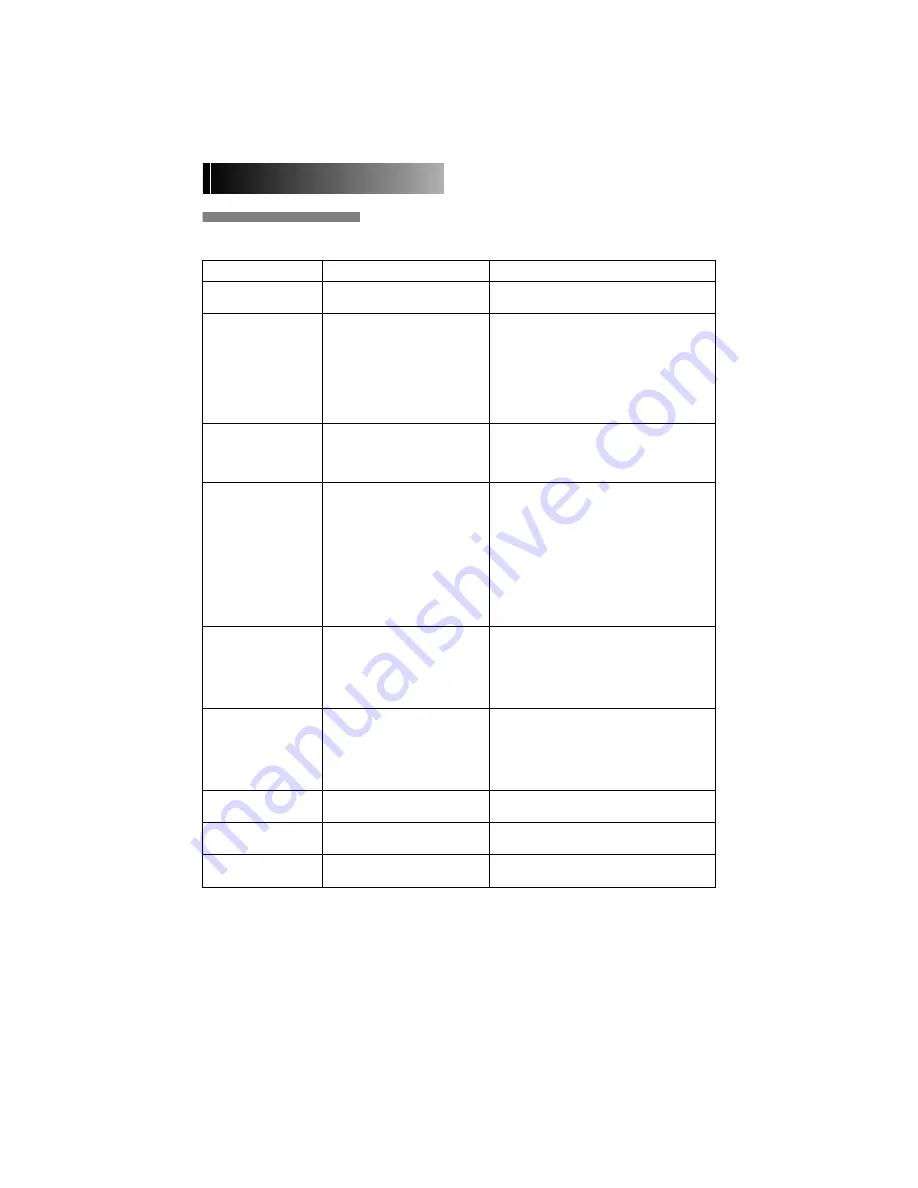

TROUBLESHOOTING

PROBLEM

POSSIBLE CAUSE

SOLUTION

Base will not fully tighten

onto the pipe.

Vise handle has run out of threads.

Loosen vise handle and position one link tighter on

chain slot. Re-tighten vise handle.

Motor will not run.

1) Tool is not plugged in.

2) A fuse is blown, or the circuit

breaker is off or tripped.

3) Motor trigger switch is defective.

4) Plug is not making good contact

with the receptacle.

5) Tool cord is damaged.

1) Plug the tool into the proper voltage outlet or

extension cord.

2) Replace the power supply fuse, or reset the

breaker.

3) Replace the motor trigger switch.

4) Inspect the connection and make repairs, as

necessary.

5) Replace the tool’s cord.

Pilot drill will not cut.

1) Drill motor is running in reverse.

2) Pilot drill is not tight in the arbor.

3) Pilot drill is dull.

1) Move the motor switch to the forward position.

2) Tighten the arbor’s set screw. Make sure it

engages the pilot drill’s flats.

3) Replace the pilot drill.

Hole saw blade will not

cut.

1) Drill motor is running in reverse.

2) Hole saw blade is dull.

3) One or more teeth have been

broken off the hole saw blade.

4) Pipe has a hard spot or a hard weld

seam.

5) Chips are stuck in the cut.

1) Move the motor switch to the forward position.

2) Replace the hole saw blade.

3) Replace the hole saw blade. Inspect the cut to see

if teeth are lodged in the pipe. Remove lodged

teeth with a center punch or a small chisel (wear

eye protection).

4) Use a sharp hole saw blade and generously

lubricate the cut with thread-cutting oil. Cut the

hole slowly.

5) Remove chips from the hole saw’s teeth and the

cut.

Excessive torque is

required to rotate the

feeder knob.

1) Drill motor is running in reverse.

2) There is a lack of lubrication on the

feeder rod.

3) The gib is too tight.

1) Move the motor switch to the forward position.

2) Lubricate the feeder rod according to the

instructions in the “Maintenance” section of this

manual.

3) Re-adjust the gib according to the instructions in

the “Maintenance” section of this manual.

Drill motor gets very hot.

1) Holes are being cut too fast.

2) Hole saw blade is dull.

3) An undersized or too long of an

extension cord is being used.

1) Feed the hole saw into the cut at a moderate rate,

and do not bog down the motor.

2) Replace the hole saw blade.

3) Replace the extension cord with one of the proper

size and length (refer to “Power Requirements”

section in this manual).

Excessive side-to-side

play is occurring.

Gib is out of adjustment.

Adjust the gib, according to the instructions in the

“Maintenance” section of this manual.

Pilot drill does not retain

the coupon.

Coupon retaining drill bit is damaged.

Replace the pilot drill.

Hole saw life is short.

Speed control dial is set too high.

Set the speed control dial to the recommended

setting listed in this manual.

HCT908

Victaulic

®

Factory Representatives and Distributor Stocks Worldwide

Victaulic reserves the right to change product specifications, designs and standard equipment

without notice and without obligation.

TM-HCT908

3022 Rev.B

9/01

RM00908000