19

vent it is necessary to check, if the 3/4“ socket usage, which can be both in pipeline and on boiler, ensures

complete immersion of the thermostatic vent element after the vent installation. After the vent has been

installed in socket, connect the down pipe, in which the hot water from boiler will flow to drain, to „C“(see. fig.

no. 9). The cooling water inlet, which will cool the boiler after setting the vent in operation, is connected (see

fig. No. 10) to „A“ (see fig. no. 9). The filter for mechanical impurities must be installed in the cooling water

inlet. It is necessary to connect the pipeline to „B“ (see. fig. no. 9) and the pipeline is to be led into reverse

flow pipe of heating system near the boiler (see fig. no. 10).

Regular maintenance

Once a year it is necessary to turn the safety vent’s head to remove possible impurities formed in the vent.

Clean the cooling water inlet filter.

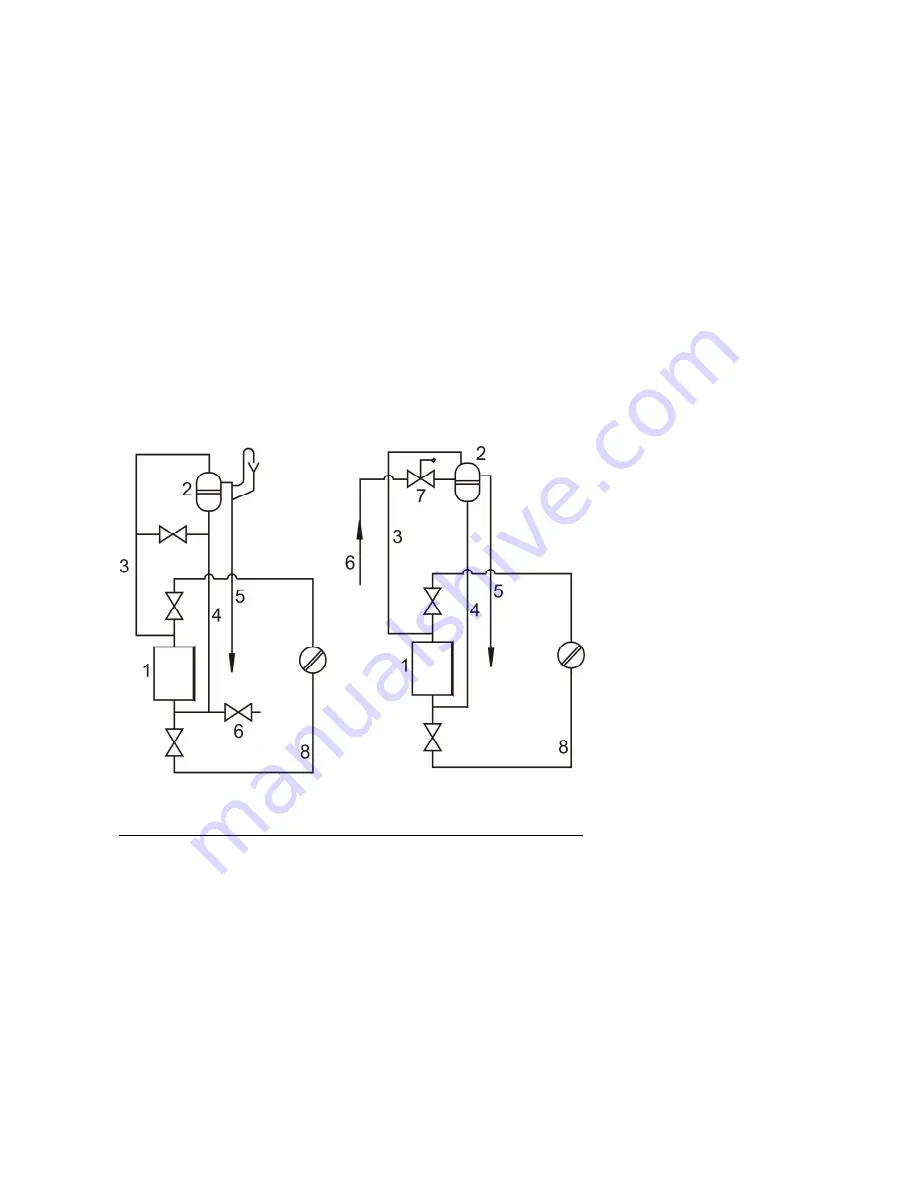

In case of using an open expansion tank it is not necessary to use a pressure protecting device

against overheating.

Every heat source in an open heat system must be connected with an open expansion tank positioned at the

highest point of the heat system. The expansion tanks must be rated in the way that they can contain the

changes in water volume resulting from heating and cooling.

The open expansion tanks must be equipped with non-closable bleeder and an overflow pipes. The overflow

pipe must be designed in the way that it safely drains off the maximum flow volume entering the system. This

can be achieved by rating the overflow pipes by one DN higher than that of the filling piping. The expansion

tanks and their connecting pipes must be designed and positioned in the way that freezing is reliably

inhibited.

Fig. no. 11

The examples of open expansion tanks connection

2.9

Equipment for heat withdrawal – accumulation tank

In case that the required volume of heating system exceeds 300 l, we recommend to install the accumulation

tank.

The calculation of the minimum volume of stack heat exchanger:

V

sp

= 15T

b

x Q

N

(1-0,3 x (Q

H

/Q

min

))

where:

V

sp

accumulation tank volume in l

Q

N

nominal heat output in kW

T

b

burning time in hours

Q

H

thermal load of buildings in kW

Q

min

the minimum heat output in kW

The dimensions of accumulation tanks for central heating boilers that are operated with individual prescribed

fuels, must be set according to the output, which needs the biggest accumulation tank. This type of

accumulation tank isn´t necessary in case that the calculated volume doesn´t exceed 300 l.

1 Heat source

2 Expansion tank

3 Safety piping

4 Expansion piping

5 Overflow piping

6 Filling piping

7 Water level limiter

8 Reverse piping

Содержание Hercules U 24

Страница 1: ...Hercules U26 Návod k obsluze VIADRUS HERCULES U 24 MANUAL FOR BOILER OPERATION AND INSTALLATION ...

Страница 30: ...30 ...

Страница 32: ...32 Updating date 6 2013 GB ...