Rev. 6/25/2019

CYL-HLT MANUAL

Copyright 2019 Vestil Manufacturing Corp. 6 of 7

RECORD OF SATISFACTORY CONDITION (THE “RECORD”)

Record the condition of the lifter before putting it into service. Thoroughly photograph the unit from multiple

angles so that all fasteners and operating mechanisms are clearly visible. Take close range photographs of the

labeling applied to the truck. Raise and lower a cylinder. Describe the operation of the winch. Describe sounds

heard as the cylinder rises and descends. Include detailed descriptions of the frame, rollers, casters, carriage,

mast rollers, and the lifting mechanisms (winch, cable, and sheaves). How much effort is required to turn the

winch? Apply the caster brakes. Photograph the brakes. Try to move the truck with the brakes applied and

describe how well the brakes resist movement. Collate all photographs and writings into a single file. Give the file

a name that clearly identifies it. This file is a record of the unit in satisfactory condition. Compare the findings of all

inspections to the record to determine whether the truck is in satisfactory condition. Purely cosmetic changes, like

damaged paint/powder coat are not changes from satisfactory condition. However, touch-up paint to be applied to

all affected areas as soon as damage occurs.

INSPECTIONS & MAINTENANCE

Regular inspections and maintenance are necessary to keep the device in normal condition. Compare the

results of each inspection to the

to determine whether the unit is satisfactory condition or requires repairs

or replacement parts. If you are uncertain whether a part requires repair or replacement, contact

to discuss your concerns.

•

Periodically lubricate moving parts.

•

Keep the product clean and dry.

•

Only use manufacturer-approved replacement parts.

Inspect the lifter at least once per month to confirm satisfactory condition. Do not return the lifter to service

unless/until it is in satisfactory condition.

1) Examine the frame for cracked welds, metal fatigue, rust, and corrosion that affects the structural integrity of

the lifter. The structure should be clean, square and rigid, and free of rust and corrosion. Remove dirt and

debris.

2) Inspect the winch and cable. Sheaves should turn smoothly as the cable passes over them. The cable should

be free of elongations, bird-caging, thinning, broken/cut strands, and rust and corrosion. The winch should turn

smoothly in both directions. It should be solidly fastened to the frame of the lifter.

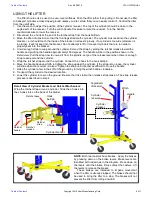

3) Check the ratchet mechanism and ratchet strap. Release/extend the strap. See

handle back-and-forth to retract/tighten the strap. You should not be able to pull strap from the spindle unless

the ratchet has been released. The strap must not be cut, substantially worn, fraying, etc.

4) Inspect the casters. Move the lifter a short distance to confirm that each caster rolls smoothly and is securely

fastened to the lifter. The wheel material should not be cracked, severely or unevenly worn, or damaged in

other ways that affect its ability to support weight or roll easily.

5) Labels: confirm that all labels are present, undamaged and readable. See

LABELING DIAGRAM

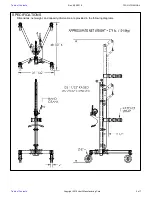

The unit should be labeled as shown in the diagram.

However, label content and location are subject to change

so your product might not be labeled exactly as shown.

Thoroughly photograph the unit when you first receive it as

discussed in the

Record of Satisfactory Condition

this manual. Make sure that your Record includes a

photograph of each label. Modify this diagram, if necessary,

to indicate labeling actually applied. Replace all labels that

are, damaged, missing, or not easily readable (e.g. faded).

Contact the

online at

http://www.vestilmfg.com/parts_info.htm

to order

replacement labels

. You may also call (260) 665-7586 and

ask the operator to connect you to the

A: Label 728

B

A

B: Label 287