Vertiv

|

200 A Distribution Fuse Panel Assembly Installation & User Manual (UM563317)

|

Rev. B

12

INSTALLING THE DISTRIBUTION FUSE PANEL

The product can be used at +55 °C (+131 °F) with a maximum of 100 A per side / 200 A total with a one (1) inch

space provided above the unit.

The product can be used at +65 °C (+149 °F) with a maximum of 80 A per side / 160 A total without a space

provided above or below the unit.

Securing the Distribution Fuse Panel to a Relay Rack or a Cabinet Equipment Rack

DANGER!

If the distribution fuse panel is mounted in a relay rack, the relay rack must be securely

anchored to the floor before the distribution fuse panel is installed.

NOTE!

Ventilation holes in the distribution fuse panel must not be blocked.

The distribution fuse panel is designed to mount in a standard 19” or 23” relay rack or equipment rack having 1”

or 1-1/4” multiple drillings.

•

Two 19” mounting brackets are furnished (adjustable for flush front mounting or 2”, 4”, or 5” front

projection mounting).

•

Two 23” mounting brackets are furnished (adjustable for flush front mounting or 2”, 4”, or 5” front

projection mounting).

on page 9 for overall dimensions.

Procedure

1.

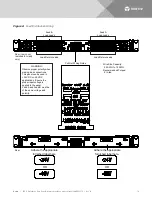

Attach the furnished 19” or 23” mounting brackets to the distribution fuse panel. Note that bracket

mounting holes are provided on the side of the distribution fuse panel to allow for a flush front mounting

or a 2”, 4”, or 5” front projection mounting. Torque mounting bracket to distribution fuse panel hardware

to 11 in-lbs.

2.

Position the distribution fuse panel in the relay rack or cabinet equipment rack.

3.

Secure the distribution fuse panel to the relay rack or cabinet equipment rack using hardware as shown

in

(see

for recommended torque). Use grounding washers as indicated in

NOTE!

Install (orient) the ground washers so the teeth dig into the mounting angles for a secure

ground connection.

NOTE!

Compliance with Telcordia GR-1089-CORE requires that prior to mounting the system to the

equipment rack:

•

All paint must be removed from the front surface of each equipment rack rail where it mates with a

shelf-mounting bracket, so that good metal-to-metal contact can be established between the shelf

and rack.

•

The shelf-to-rack mating surfaces must be cleaned.

•

Electrical anti-oxidizing compound must be applied to the shelf-to-rack mating surfaces.

Содержание NetSure NSFP200

Страница 24: ...UM563317 RB 05 17...