4-10

39014-03 06/16

VERSALIFT VST-36/40/47/52-I

OPERA

TION

The optional lifting eye has been designed to

accommodate limited material handling. Always

extend the outriggers (if so equipped) and fully retract

the inner boom when using the boom lifting eye. Boom

movements should be smooth to avoid swinging the

load. Do not exceed the load limits stated on the

decal beside the lifting eye. Do not drag the load with

the lifting eye. This is a bad practice and subjects

the unit to damaging sideloads. When lifting loads,

position the lower boom directly over the load before

lifting. The platform should be empty when lifting loads.

When the truck is not level, extreme caution must be

used when rotating loads toward the low side because

the truck stability will be affected.

The platform must

not be used for material handling.

The platform

was designed to lift personnel only.

DANGER:

INCREASING THE

HORIZONTAL DISTANCE FROM THE TRUCK TO

THE LOAD WILL REDUCE THE STABILITY OF THE

TRUCK AND MAY RESULT IN DEATH OR

SERIOUS INJURY.

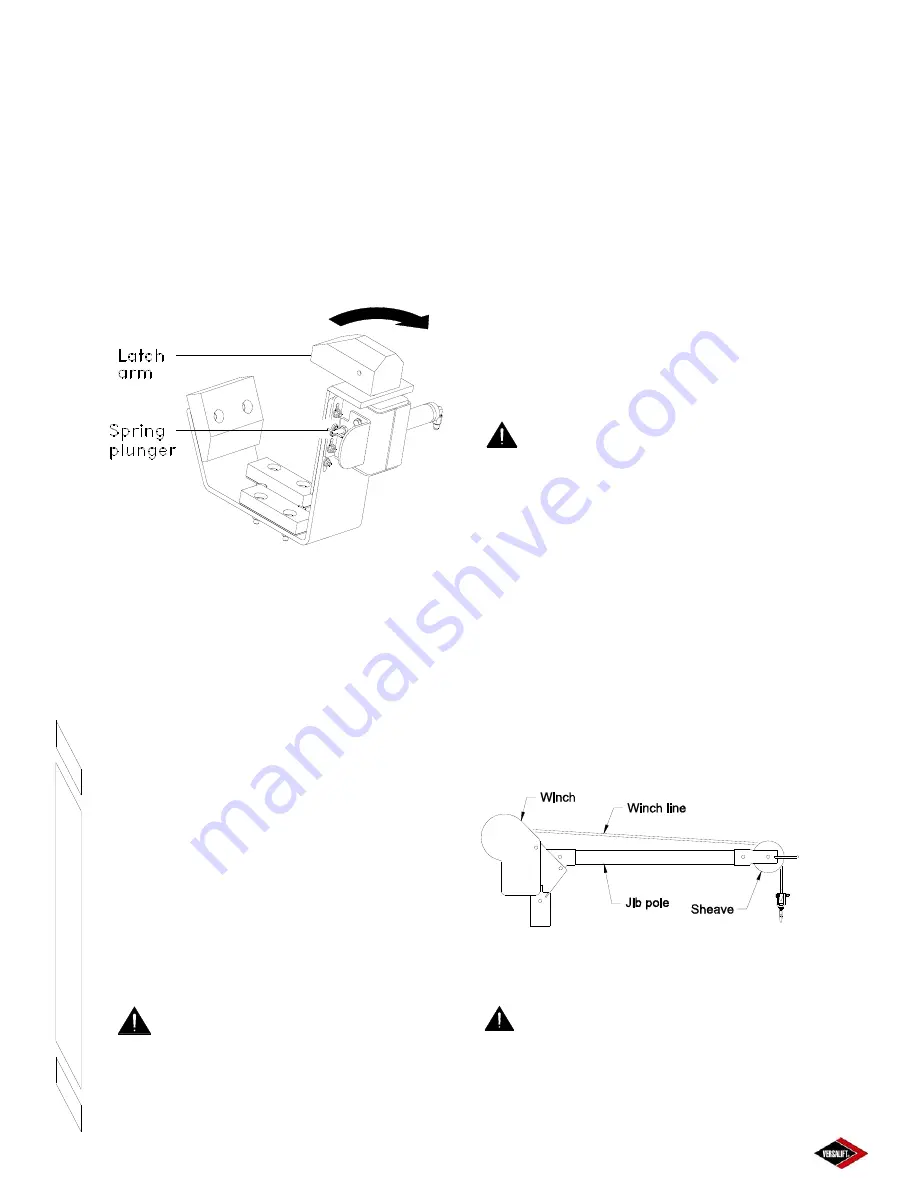

MANUAL JIB OPERATION

The optional material handling system is designed to

lift loads to the work site at the platform. The main

components of this system are the sheave, winch

line, jib pole, and the winch. The jib pole tilts and

rotates manually. Although some of the components

of the jib and winch are made from non-conductive

materials, they are not tested or maintained as

insulating. Therefore, the entire jib and winch

assembly, including the jib pole and rope, must be

considered conductive and have no insulating value.

Manual Jib Major Components

Figure 4.9

DANGER:

DEATH OR SERIOUS

INJURY MAY RESULT FROM MISUSE OR

FAILURE CAUSED BY MISUSE OF THE AERIAL

LIFT OR ITS COMPONENTS. BEFORE

OPERATION, KNOW THE INSTRUCTIONS AND

LIMITATIONS OF THE LIFT AND THE MATERIAL

HANDLING SYSTEM.

Over-ride Procedure:

1.

Danger

– Make sure the hydraulic power source

is off.

2.

Release the spring plunger by rotating the “T”

handle.

3.

Manually rotate the latch arm 90° clockwise until

it snaps and is held by the spring plunger.

To Release Over-ride:

1.

Caution

– The latch is spring loaded. Keep

fingers clear to prevent pinching.

2.

Slightly rotate the latch arm clockwise to remove

the load from the spring plunger.

3.

While holding the latch arm, pull the spring

plunger out and rotate the “T” handle to lock the

spring plunger in the “out” position.

4.

Carefully allow the latch arm to rotate counter-

clockwise under spring power until it stops.

LIFTING EYE (OPTION)

This aerial lift is designed primarily as a personnel lift.

When tools or equipment are included with the operator

in the platform the combined weight must not exceed

the rated load capacity of the aerial lift.

DANGER:

NEVER EXCEED THE

RATED LOAD CAPACITY OF THE AERIAL LIFT.

STRUCTURAL DAMAGE OR INSTABILITY MAY

RESULT, CAUSING DEATH OR SERIOUS INJURY.

Содержание VST-36-I

Страница 2: ......

Страница 4: ......

Страница 6: ......

Страница 11: ...2 3 39014 03 06 16 VERSALIFT VST 36 40 47 52 I RESPONSIBILITIES SAFETY ...

Страница 12: ...2 4 RESPONSIBILITIES SAFETY 39014 03 06 16 VERSALIFT VST 36 40 47 52 I ...

Страница 18: ......

Страница 27: ...3 9 39014 03 06 16 VERSALIFT VST 36 40 47 52 I SPECIFICATIONS ...

Страница 28: ...3 10 39014 03 06 16 VERSALIFT VST 36 40 47 52 I SPECIFICATIONS ...

Страница 29: ...3 11 39014 03 06 16 VERSALIFT VST 36 40 47 52 I SPECIFICATIONS ...

Страница 30: ...3 12 39014 03 06 16 VERSALIFT VST 36 40 47 52 I SPECIFICATIONS ...

Страница 31: ...3 13 39014 03 06 16 VERSALIFT VST 36 40 47 52 I SPECIFICATIONS ...

Страница 36: ...3 18 39014 03 06 16 VERSALIFT VST 36 40 47 52 I SPECIFICATIONS ...

Страница 37: ...3 19 39014 03 06 16 VERSALIFT VST 36 40 47 52 I SPECIFICATIONS ...

Страница 38: ......

Страница 60: ...6 4 39014 03 06 16 VERSALIFT VST 36 40 47 52 I DAILY VISUAL INSPECTION ...

Страница 61: ...6 5 39014 03 06 16 VERSALIFT VST 36 40 47 52 I DAILY VISUAL INSPECTION ...

Страница 62: ...6 6 39014 03 06 16 VERSALIFT VST 36 40 47 52 I DAILY VISUAL INSPECTION ...