5.2.1

Cleaning

Soot deposits may form inside the furnace, depending on the process. At appropriate

intervals remove these by heating as indicated in the General Operation Notes.

The product's outer surface may be cleaned with a damp cloth. Do not

allow water to enter the interior of the case or chamber. Do not clean

with organic solvents.

5.3

Element Ageing

Silicon Carbide heating elements gradually increase in resistance with use and the

power of the furnace gradually declines until the furnace can no longer keep up with its

program. To maximise the element life it is advisable to follow the recommendations

below:

a. Do not run the furnace at higher temperatures than you need. See section 4.7.2.2.

b. Do not select unnecessarily fast ramp rates. See section 4.7.2.2.

There is a feature in the Software which allows the power from the elements to be

adjusted. This 'power limit' is pre-set at Carbolite Gero. As the element performance

declines the available power can be increased to compensate. The maximum power

figure available is 100 (%), if the furnace performance is still poor when the power is set

to 100 (%) the elements must be replaced.

To adjust the power settings proceed as follows:

With the software open, select 'tools' 'Calibration' from the text menu bar.

The 'Controller Calibration Settings' window will appear.

At this stage it is a good idea to write down the original power limit value.

In the 'Power Limit' number box either enter a value directly or use the up and down

arrows to adjust the % power limit.

48

Содержание CARBOLITE GERO CAF G5

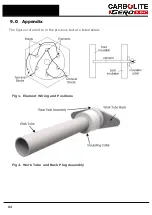

Страница 63: ...Fig 3 Front Tube Seal Assembly Fig 4 Door Arm Assembly 63 ...

Страница 64: ...Fig 5a Camera Mounting Bracket Fig 5b Lens and Camera Assembly 64 ...

Страница 65: ...Fig 5c Sliding the Camera Mounting Bracket Assembly onto the Door Arm 65 ...

Страница 66: ...Fig 5d Securing the Camera Mounting Bracket Assembly to the Door Arm 66 ...

Страница 67: ...Fig 5e Mounting the Lens and Camera Assembly 67 ...

Страница 68: ...Fig 5f Lens and Camera Assembly in Position 68 ...

Страница 69: ...Fig 6a Rear View of the Standard CAF G5 Furnace Showing Brick Box Assembly 69 ...

Страница 70: ...Fig 6b Rear View of the CAF G5 Biomass Furnace with Rear Illumination Showing Brick Box Assembly 70 ...

Страница 71: ...Fig 7 Front Tube Seal Position 71 ...

Страница 72: ...Fig 8 Tube End Seal Assembly Tightening Sequence Fig 9 Work Tube Front Support 72 ...

Страница 73: ...Fig 10 Fitting the Door Arm Assembly Fig 10a Adjusting the Door Arm Assembly 73 ...

Страница 74: ...Fig 11a Furnace Case and Controls 74 ...

Страница 75: ...Fig 11b Gas Inlet Pipe Fig 12 Positioning the Furnace 75 ...

Страница 76: ...Fig 13a Positioning Samples on the Sample Carrier Fig 13b Loading Samples into the Mouth of the Work Tube 76 ...

Страница 77: ...Fig 13c Loading Samples into the Work Tube 77 ...

Страница 78: ...Fig 16 File Folder 78 ...

Страница 79: ...Fig 17 Door Arm Assembly Exploded View 79 ...

Страница 82: ...SST DT HT FT Fig 18 Report Sheet Page 2 Side View Plan View Fig 19 Formed Wire Sample 82 ...

Страница 83: ...Fig 20 Sample Carrier Sample Tiles and Sample Positions 83 ...

Страница 84: ...Fig 21a Coal and Coke Test Piece Mould Fig 21b Biomass Test Piece Mould and Hand Press 84 ...

Страница 85: ...Fig 22 Sample Loading Tool Fig 23 Camera Ethernet Connection 85 ...

Страница 86: ...Fig 24 LED Driver Connection 86 ...

Страница 87: ...Notes Service Record Engineer Name Date Record of Work ...