SERVICE

Service - 19

Back Lapping

Never make an adjustment with the engine running.

Contact with the reel, bed knife, or other sharp

objects may result in personal injury.

The reel blades and bed knife of each cutting unit

should be kept in good condition. Sharp blades will

increase the efficiency and improve the quality of the

cut. Each blade and bed knife should be inspected

prior to back lapping to locate sections that do not

cut well, or if the blade or bed knife is worn or

damaged to the point that regrinding or replacement

is required.

Each cutting unit is equipped with a bypass valve on

the drive motor. These bypass valves enable each

cutting unit to be back lapped individually.

1. Clean the cutting units.

2. Park on a level surface. Engage the parking brake,

lower the reel mower to the ground, shut off the

power unit engine, and remove the ignition key.

3. Check the entire width of the reel cutter blade to

locate sections that do not cut well.

4. Only back lap one reel at a time. For the other

two reels, turn the hydraulic motor bypass lever

to the stop position.

5. Apply polishing agent with a brush to those loca-

tions that cut newspaper well. Do not apply the

polishing agent to those locations that do not cut

newspaper well. The polishing agent should be

a mixture of lapping powder (#150 or #200) and

oil, mixed in a 1:3 or 1:4 ratio.

6. Adjust the reel cutter to the bed knife the appro-

priate amount for back lapping. (Refer to blade

adjustment to bed knife section for instructions.)

7. Adjust the reel speed control lever to the back

lap position so the reels will operate in reverse.

8. Return to the power unit seat, start the engine,

and engage the PTO. Rotate the blades at a reel

speed of approximately 200 rpm. After several

minutes, stop the PTO, shut off the engine, and

inspect the reel blades and bed knife.

9. Adjust reel cutter to bed knife as required. Apply

additional polishing agent. Back lap until a sharp,

uniform cutting edge is achieved.

10. After back lapping is completed, thoroughly clean

the polishing compound from the reel blades and

bed knife. Apply a thin coating of oil to the sharp-

ened edges of the blades and bed knife.

11. Return the reel speed control lever to the desired

position for mowing. Activate all hydraulic drive

motors by turning the hydraulic drive motor

bypass lever to the run position.

Reel Grinding

Drive Adapter: part number 07.02074

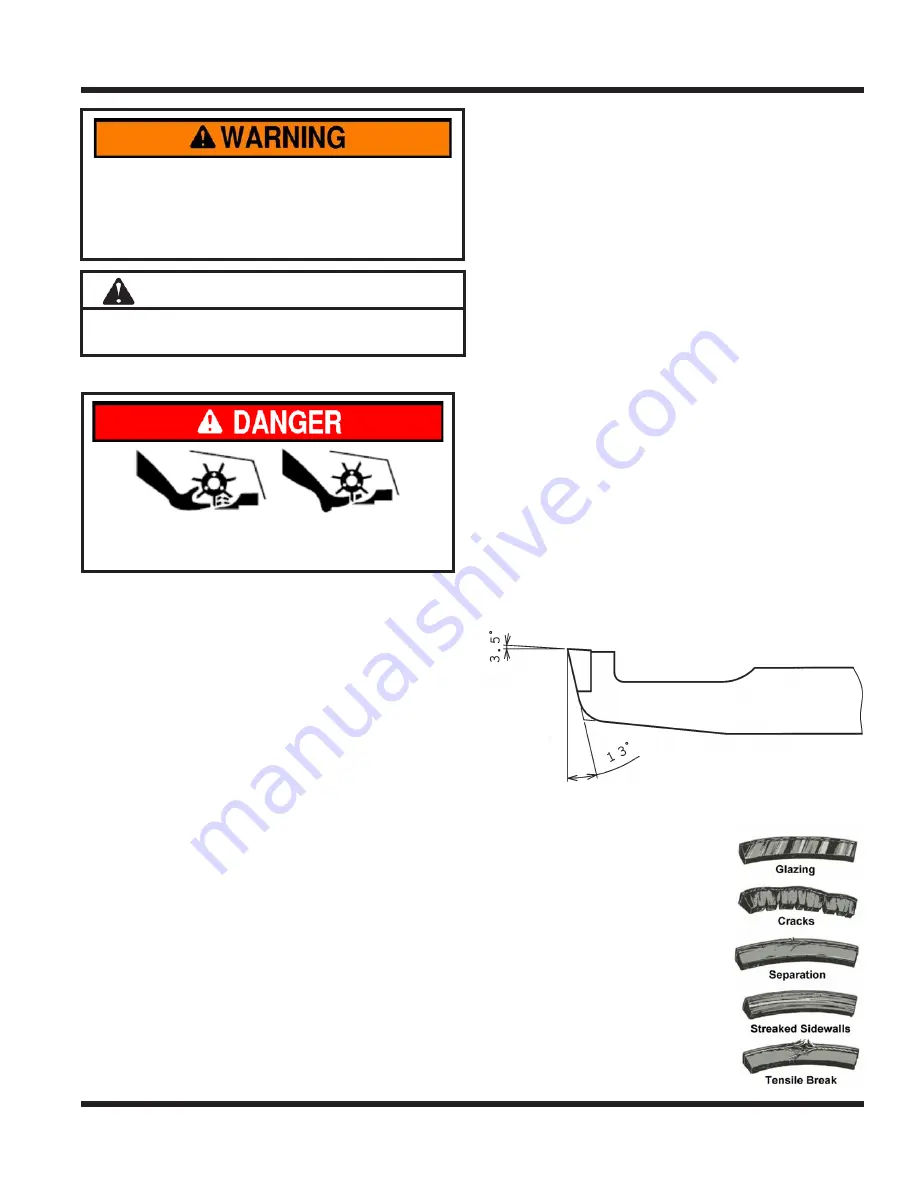

Bed Knife Grinding

Top Angle = 3.5°

Front Angle = 13°

Drive Belt Inspection/Replacement

Inspecting the drive belt on the

reel mower can prevent sudden

belt failure by finding problems

before they cause the belt to

break.

Typical wear on the drive belt

may result in the conditions

shown in the diagram. If any of

these conditions occur, the drive

belt will require replacement.

SERVICE

Always set the parking brake, shut off power

unit engine, remove the ignition key, and ensure

all moving parts have come to a complete stop

before inspecting components or attempting any

repair or adjustment.

Attention

If any component requires replacement, use only

original Ventrac replacement parts.

Содержание MR740

Страница 28: ...PARTS Illustrated Parts 28 Use only original Ventrac replacement parts ILLUSTRATED DRAWING Hydraulic Drive ...

Страница 36: ...PARTS Illustrated Parts 36 Use only original Ventrac replacement parts ILLUSTRATED DRAWING Reel Head ...

Страница 38: ...PARTS Illustrated Parts 38 Use only original Ventrac replacement parts ILLUSTRATED DRAWING Front Rear Rollers ...