VTUSC6

14.11.2011

©Velleman nv

5

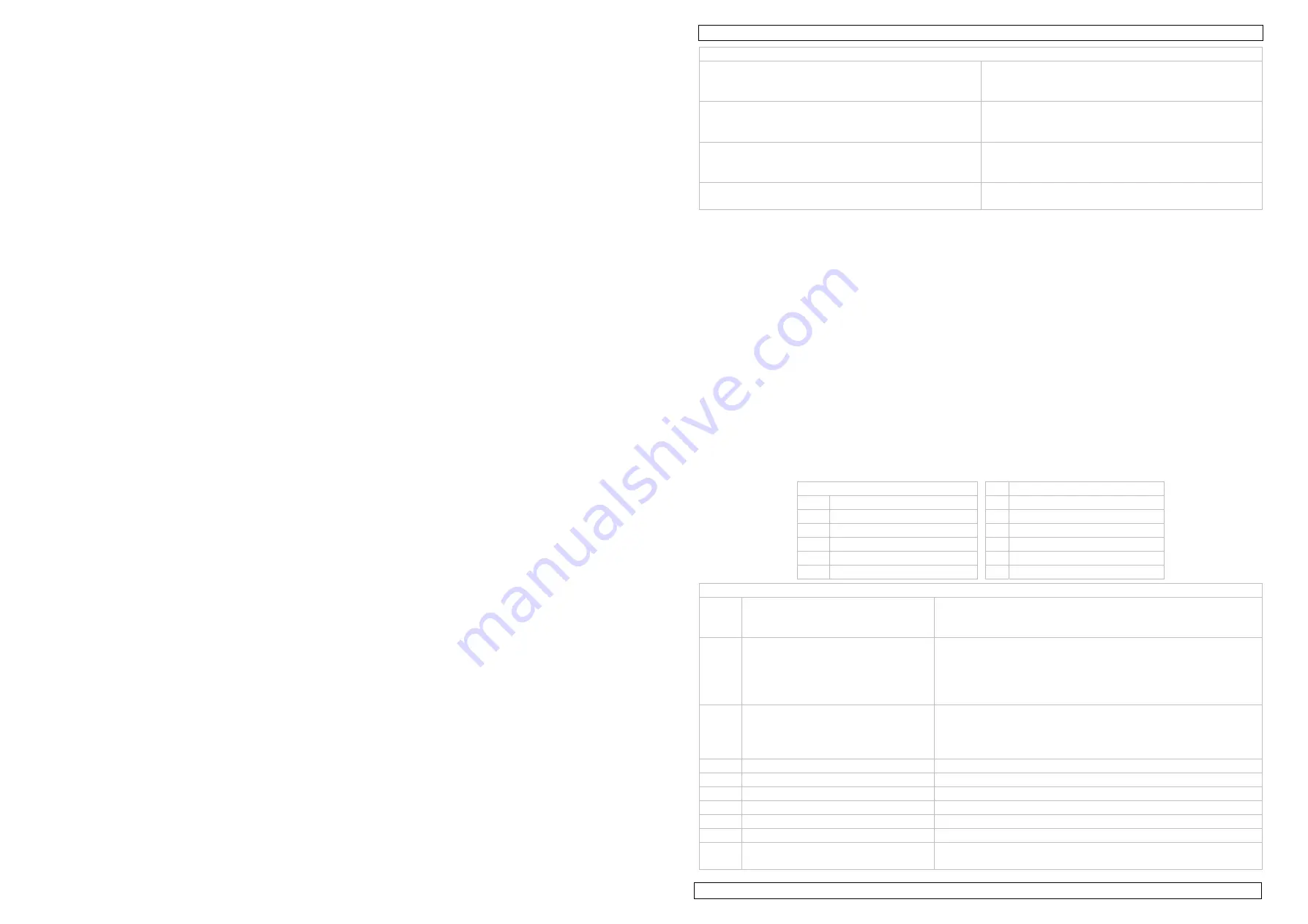

ITEMS NOT SUITABLE FOR ULTRASONIC CLEANING

Soft jewellery:

pearls, emerald, ivory, coral, agate, sea turtle

shells etc...

As these items are soft, scratching may occur

during the cleaning process.

Welded, plated, glued items

Ultrasonic cleaning may increase the gaps inside

welded joints, plated coating or glue which may

lead to breaking loose.

Watches:

unless diving watches with depth rating over 50m

(150 ft)

The strong penetration capabilities of the

ultrasonic waves may cause water to penetrate

weaker sealed watches.

Other:

glass, ceramic, camera filters with known cracks

Crack size may be increased by the ultrasonic

waves.

4.

Features

•

for cleaning of: jewellery, dentures, eyeglasses, electric shaver heads, CDs/VCDs/DVDs etc.

•

2 colour LED display: 1 to 30 minute timer, 5 temperature settings, working status indicators

•

cooling fan

•

two ceramic heaters

•

overheating protection

5.

Working principle

The principle behind ultrasonic cleaning is cavitation.

When the ultrasonic cleaner is switched on, 3-dimensional sound waves of alternating positive

and negative pressure are generated and transmitted into the water in the tank. These sound

waves created micron-sized bubbles that grow and build up energy during negative pressure and

implode at a very high speed during positive pressure (43,000 times per second). These

implosions of high energy bubbles create cavities that literally pull contaminants of the surface

(at speeds up to 400km/h). Due to the size of the bubbles, they are effective in removing

contaminants from the smallest of crevices but harmless to the substrate itself.

Usually water is used as cleaning agent as it is inexpensive and environmentally safe.

6.

Overview

Refer to the illustrations on page 2 of this manual.

general

G

drainage valve

A transparent lid

H drainage pipe

B LED light

I power button

C stainless steel tank

J power socket

D control panel

K hose

E housing

L power cord

F handles

M basket

control panel

1

status indicator

Green: normal working status, ready.

Red: fault condition, overheated. Let the VTUSC6 cool

down for at least 15 minutes.

2

On/off button

Press to switch the device on. Default time and

temperature settings are shown (5 minutes, 40°C). Press

again to start the cleaning process; it stops automatically

when the timer expires. Press the button at any time to

interrupt the cleaning process.

3

function button

Press to start degassing function (degas). The indicator

[4] will flash during the degas process (±2minutes). To

interrupt the process, press the button again. See note

below the table.

4

degas indicator

Flashing during the degassing process.

5

normal cleaning indicator

Illuminated during normal cleaning process .

6

heater indicator

Illuminated when heater is active.

7

actual liquid temperature

Displays temperature of liquid in the tank.

8

timer display

Countdown timer indicates remaining cleaning time.

9

set temperature

Indicates the selected temperature.

10 quick set time button (Time)

Press to show initial timer (05:00). Press again to

increase the timer by 5 minutes.