8

3 Supplement

VEGAMAG 81 •

44905-EN-190118

Pressure-Temperature-Assignment - ASME flanges

Material 316

Temperature range

Class 150 Class 300 Class 400 Class 600 Class 900 Class

1500

Class

2500

-29 … +38 °C

19 bar

49.6 bar

66.2 bar

99.3 bar

148.9 bar 248.2 bar

413.7 bar

50 °C

18.4 bar

48.1 bar

64.2 bar

96.2 bar

144.3 bar 240.6 bar

400.9 bar

100 °C

16.2 bar

42.2 bar

56.3 bar

84.4 bar

126.6 bar 211 bar

351.6 bar

150 °C

14.8 bar

38.5 bar

51.3 bar

77 bar

115.5 bar 192.5 bar

320.8 bar

200 °C

13.7 bar

35.7 bar

47.6 bar

71.3 bar

107 bar 178.3 bar

297.2 bar

250 °C

12.1 bar

33.4 bar

44.5 bar

66.8 bar

100.1 bar 166.9 bar

278.1 bar

300 °C

10.2 bar

31.6 bar

42.2 bar

63.2 bar

94.9 bar 158.1 bar

263.5 bar

325 °C

9.3 bar

30.9 bar

41.2 bar

61.8 bar

92.7 bar 154.4 bar

257.4 bar

350 °C

8.4 bar

30.3 bar

40.4 bar

60.7 bar

91.0 bar 151.6 bar

252.7 bar

375 °C

7.4 bar

29.9 bar

39.8 bar

59.8 bar

89.6 bar 149.4 bar

249 bar

390 °C

6.5 bar

29.4 bar

39.3 bar

58.9 bar

88.3 bar 147.2 bar

245.3 bar

Tab. 2: ASME B16.5-2013

Note:

You will find a complete overview of the available pro-

cess fittings in the "configurator" on our homepage at

www.vega.com/configurator.

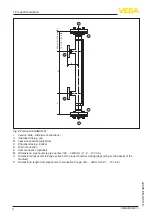

Chamber closing - bottom (C)

Pipe cap

Flange from DN 50 or 2"

Drain connection (D)

Thread G½ (DIN 3852-A), ½ NPT (ASME B1.20.1)

Thread G¾ (DIN 3852-A), ¾ NPT (ASME B1.20.1)

Flange DIN from DN 15

Flange ASME from ½"

Vent connection (E)

Thread G½ (DIN 3852-A), ½ NPT (ASME B1.20.1)

Thread G¾ (DIN 3852-A), ¾ NPT (ASME B1.20.1)

Flange DIN from DN 15

Flange ASME from ½"

Содержание VEGAMAG 81

Страница 10: ...10 Notes VEGAMAG 81 44905 EN 190118 ...

Страница 11: ...11 Notes VEGAMAG 81 44905 EN 190118 ...