7

3 Supplement

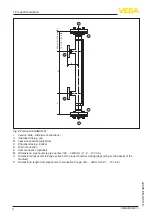

VEGAMAG 81 •

44905-EN-190118

3 Supplement

3.1 Technical data

General data

Material 316L corresponds to 1.4404 or 1.4435

Measurement requirement

Product density must be known and constant

Materials

Ʋ Bypass pipe

316L

Ʋ Float

Titanium

Ʋ Magnet gauge - Housing

Aluminium or stainless steel

Ʋ Magnet gauge - Display elements

Plastic or stainless steel

Colour of the magnet gauge

yellow/black or red/white

Gasket - Chamber closings (top/bottom)

Ʋ max. 250 °C/40 bar (482 °F/580 psig) Klingersil C-4500

Ʋ max. 390 °C/40 bar (734 °F/580 psig) Graphite

Pipe diameter (outer)

Ʋ Version 2"

ø 60.3 mm (2.37 in)

Wall thickness

2 … 5.54 mm (0.08 … 0.22 in)

Process temperature

max. 390 °C (734 °F) - see process fitting, connection

flange (B)

Process pressure

Ʋ Standard version

see process fitting - connection flange (B)

Ʋ According to pressure device directive

(PED)

max. 90 bar (1305 psig) - Cat. III, Fluid group I

Ʋ According to ASME

max. 100 bar (1450 psig)

Chamber closing - top (A)

Pipe cap

Flange from DN 50 or 2"

Process fitting - connection flange top/bottom (B)

Connections

Welded socket from ½", stub end from ½", thread from

½ NPT, flanges from DN 15 or ½"

Process pressure in bar (psig) depending on the process temperature

Pressure-Temperature-Assignment - DIN flanges

Material 316/316L (1.4401)

Pressure

range

100 °C

150 °C

200 °C

250 °C

300 °C

350 °C

390 °C

PN 40

40 bar

36.3 bar

33.7 bar

31.8 bar

29.7 bar

28.5 bar

27.4 bar

PN 63

63 bar

57.3 bar

53.1 bar

50.1 bar

46.8 bar

45.0 bar

43.2 bar

PN 100

100 bar

90.9 bar

84.2 bar

79.5 bar

74.2 bar

71.4 bar

68.5 bar

Содержание VEGAMAG 81

Страница 10: ...10 Notes VEGAMAG 81 44905 EN 190118 ...

Страница 11: ...11 Notes VEGAMAG 81 44905 EN 190118 ...