16

17

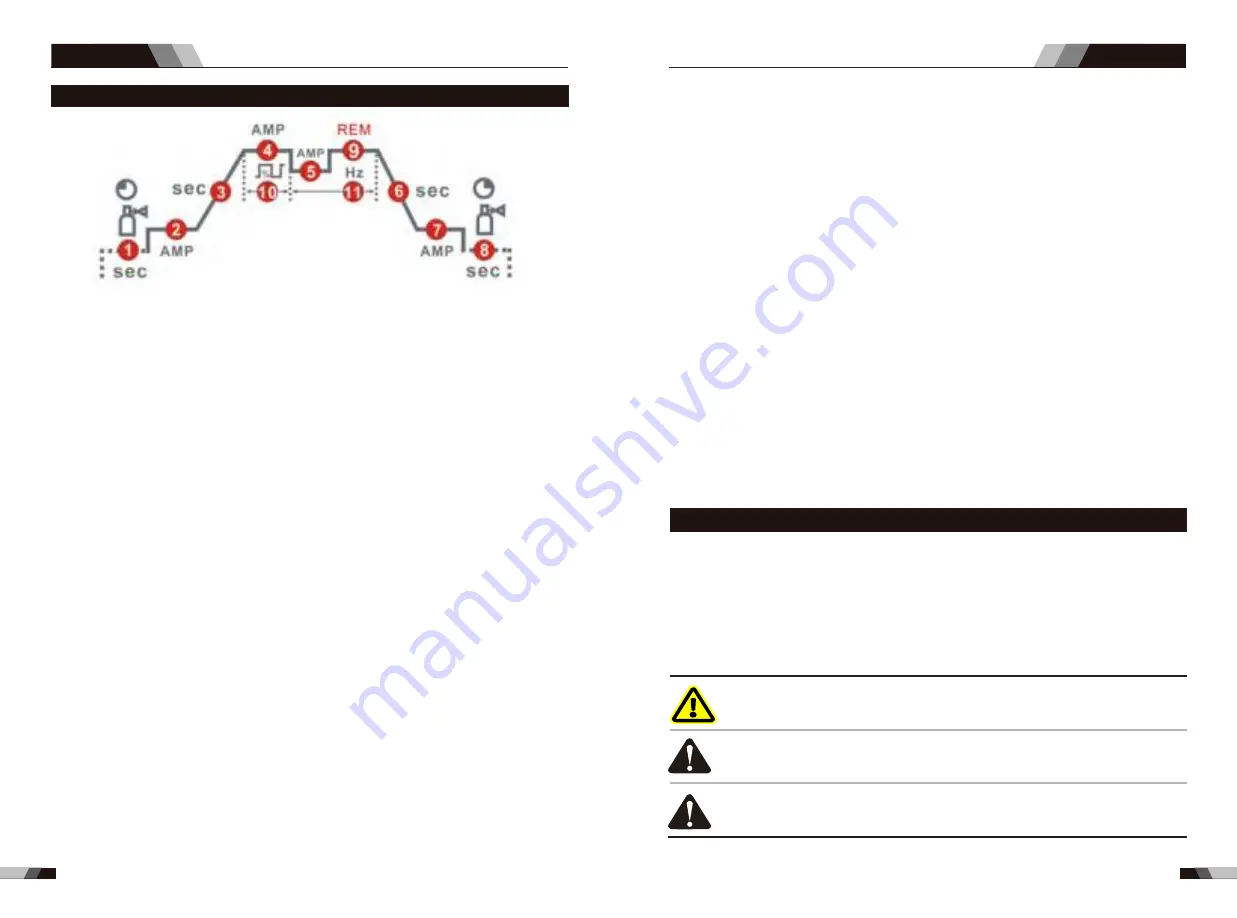

.

Gas Pre-Flow

1

Absolute setting range 0.1s to 5s (0.1S increments)

This parameter operates in TIG modes only and is used to provide gas to the weld zone

prior to striking the arc, once the torch trigger switch has been pressed. This control is

used to dramatically reduce weld porosity at the start of a weld.

2.Initial Current

The main current Setting range 10AMP to 170AMP

This parameter operates in (4T) TIG modes only and is used to set the start current for TIG.

The Start Current remains on until the torch trigger switch is released after it has been

depressed.

Note: The maximum initial current available will be limited to the set value of the base

Operation

Operation

DC PULSE

SERIES

EQUIPMENT

DC PULSE

SERIES

EQUIPMENT

3.Up Slope

Setting ranges :0.1S-10S (0.1S increments)

This parameter operates in (2T and 4T) TIG modes only and is used to set the time for the

weld current to ramp up, after the torch trigger switch has been pressed then released,

from Initial Current to High or base current.

4.Peak Current

Setting ranges

O241:10AMP to 170AMP (DC TIG mode), 10 to 170A (AC HF TIG mode)

This parameter sets the TIG WELD current. This parameter also sets the STICK weld

current.

5.Base Current

Setting ranges

O241:10AMP to 170AMP (DC TIG mode), 10AMP to 170AMP (AC HF TIG mode)

Secondary current (TIG)/pulse pause current.

6.Down Slope

Setting ranges 0.1-10s

This parameter operates in TIG modes only and is used to set the time for the weld current

to ramp down, after the torch trigger switch has been pressed to end current. This control

is used to eliminate the crater that can form at the completion of a weld.

7.End current

Setting ranges 10A-170A

This parameter operates in (4T) TIG modes only and is used to set the finish current for TIG.

The end Current remains ON until the torch trigger switch is released after it has been

depressed.

Note: The maximum crater current available will be limited to the set value of the base

current.

8.Post Flow

9. Remote Control

Setting ranges 1-10S

The system independently identifies the remote control, and when the indicator light is

on, the welding current can be adjusted by remote (foot or welding gun).

This parameter operates in TIG modes only and is used to adjust the post gas flow

time once the arc has extinguished. This control is used to dramatically reduce

oxidation of the tungsten electrode.

10.Pulse Width

Setting ranges 10%-90%

This parameter sets the percentage on time of the PULSE FREQUENCY for High

weld current when the PULSE is ON.

11.Pulse Frequency

Setting ranges 1HZ -200HZ

This parameter sets the PULSE FREQUENCY when the PULSE is ON.

3.3 Setup For STICK (MMA) Welding

WARNING

Before connecting the work clamp to the work and

inserting the electrode in the electrode holder make

sure the mains power supply is switched off.

CAUTION

CAUTION

Remove any packaging material prior to use. Do not

block the air vents at the front or rear of the Welding

Power Source.

Loose welding terminal connections can cause

overheating and result in the male plug being fused

in the bayonet terminal.

For Alkaline Electrode,connect the electrode holder to the positive welding termimal

Electrode,please connect the electrode holder to the negative welding termimal and

manufacturer. Welding current flows from the Power Source via heavy duty bayonet type

terminals. It is essential, however, that the male plug is inserted and turned securely to

achieve a sound electrical connection. Select STICK mode with the process selection

control.

a n d c o n n e c t t h e w o r k l e a d t o t h e n e g a t i v e w e l d i n g t e r m i n a l , w h i l e f o r t h e A c i d

connect the work lead to the positve welding terminal.If in doubt consult the electrode

3.2 Control Panel