Varisco S.p.A.

Z.I. Nord - Terza Strada, 9 - 35129 PADOVA – ITALY

Tel.+39.049.8294111 Email: [email protected]

Fax+39.049.8076762 Web: www.variscospa.com

5

This machine has been designed considering its nominal working performance. Any indication

concerning the nominal working performance is to be meant as a limit value, and shall not be

exceeded in any case.

1.14 SPECIFIC WARNINGS FOR PROGRESSING CAVITY PUMPS

Progressing cavity pumps must be used only according to their destination, i.e. in compliance with

the purpose which was meant for them when they were acquired.

Keep in mind that a progressing cavity pump is a positive displacement pump; hence it may

theoretically produce infinite pressure.

In the event of closed delivery pipe, due for instance to clogging or accidental closing of a valve,

the pump may generate a pressure several times greater than the maximum pressure allowed for the

plant. In this case pipes may burst, which is to be avoided in particular if hazardous fluids are

concerned.

The plant shall therefore be equipped with adequate safety devices, i.e. pressure switches, security

valves and by-pass.

During maintenance and repair on the pump make sure that:

•

the motor must be shut-off!

•

when dismantling the pump, the rules related to the discharge material handling must be

complied with (i.e., protecting apparel, smoking prohibition, etc.).

•

before restarting, all protective devices, mechanical or other (e.g. chain cover or joint cover),

must be regularly refitted.

WARNING

During use, maintenance and repairing, keep in mind your safety and follow the general European

directives concerning machines then transformed into national laws, the European regulation EN

292, specific accident-prevention rules, instructions provided by the mining authorities and comply

with the technical standards concerned.

2 FUNCTIONING

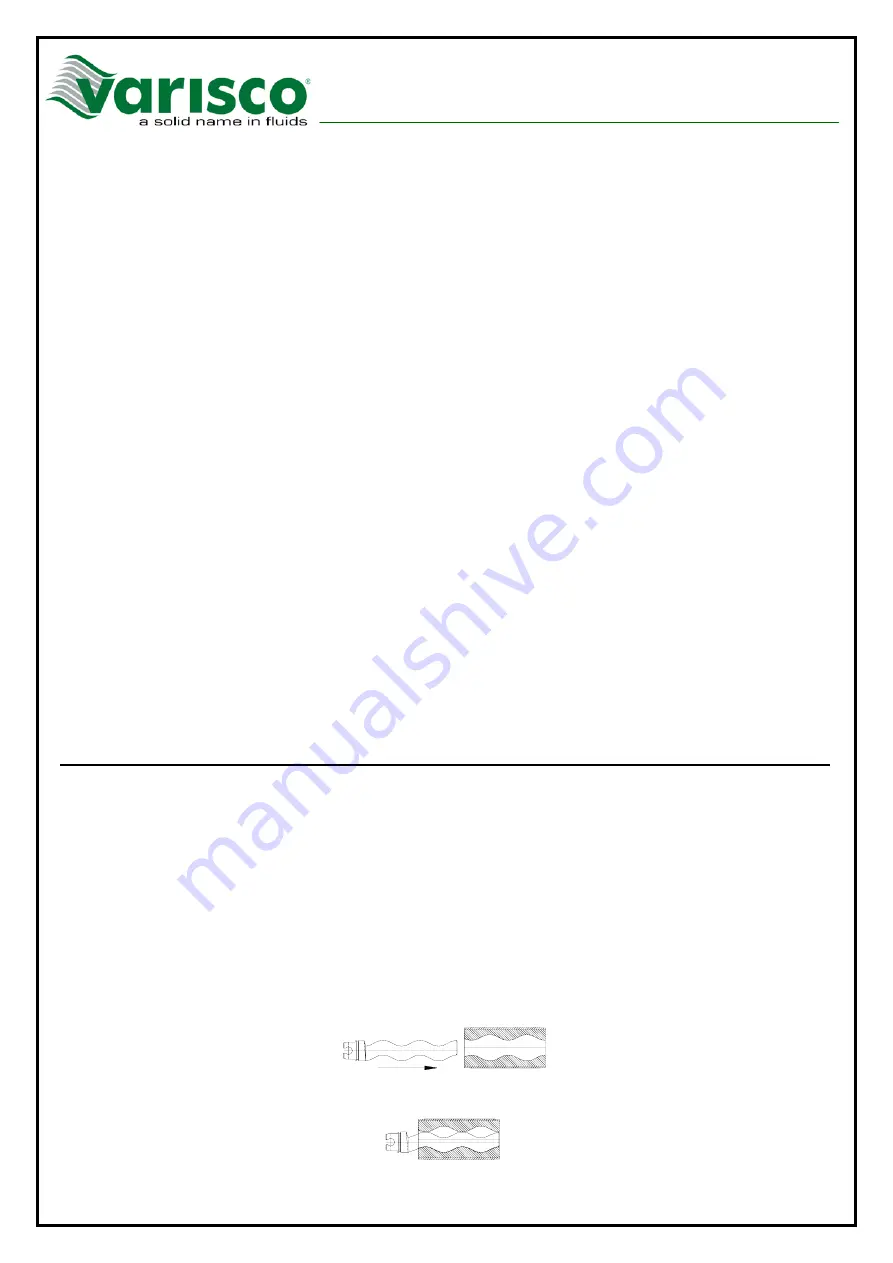

A progressing cavity pump is a rotating volumetric pump. The main parts of the system are a rotary

part called

ROTOR

(see

A

below) and a fixed part called

STATOR

(see

B

).

The rotor is a round thread screw with a very large pitch, a deep thread and a small core diameter.

The stator is double-threaded and has a pitch which is double compared to the rotor, so that between

the stator and the rotor there are delivery chambers. These move continuously from the inlet side

towards the outlet when the rotor is spinning inside the stator.

In progressing cavity pumps the axis of rotation of the rotor A does not coincide with the axis of

rotation of the motor. The rotor is driven by a double-joint shaft. This shaft absorbs eccentric

motions and shifts axial stresses towards the motor shaft.

A

B