BDR-595D Adela

14

under the cutting disk cover will do itself a partial clearance of the excessive grass and

debris. Then drive the machine against the sward again (see Chapter 5.4).

Be very careful while lifting the machine and moving the machine backwards!

b)

Engine losing speed and stalling

: release both levers on the handlebars, lift the machine

front by pushing down on the handlebars and move the machine a bit backwards. Clear the

space under the cutting disk casing and spread the cut grass across the ground. Start the

engine, switch on the cutting disk drive (see Chapter 5.3) and once again drive the machine

against the sward (see Chapter 5.4).

The engine must be always switched off when clearing the space under the upper

casing!

Tilt the machine always only backwards onto the handlebars. Be very careful while

moving under the lifted machine! Secure the machine against its spontaneous

motion!

Be very careful while cleaning the space under the cutting disk casing. Cutting edges

of the blades are sharp. You should wear protective gloves or use a suitable piece of

branch etc.

6 Maintenance, care and storage.

To ensure a long-term satisfaction with our product, it must be given proper care and

maintenance. Regular maintenance of the machine will prevent its early wear ensuring at the

same time a correct functioning of all its parts.

Follow all instructions for intervals of machine maintenance and adjustments. It is

advised that you keep records on the number of machine working hours and on the

conditions in which the machine was working (for service purposes). Similarly as the current

maintenance, the after-season maintenance of the machine should be entrusted to one of our

authorized service workshops in the case that you do not trust your own technical skills.

Regarding the machine weight, all maintenance and adjustment procedures are to

be done by two cooperating persons.

6.1 Machine lubrication.

6.1.1 Gearbox oil replacement and refilling.

When replacing oils, follow the basic hygienic principles, regulations and laws on

environment protection.

The gearing works in an oil bath. Oil volume should be checked once a month (oil

plugs see Fig. 4).

Minimum grade of gear oil should be GL-4, GL-5 according to API, 90 or 80W – 90

according to SAE.

Oil replacement in a new machine is to be made after the first

5

hours of operation and

then after

100

working hours or after the end of the season. This will ensure that the gears

Содержание BDR-595 D Adela

Страница 1: ...Brush cutter BDR 595 D Adela Instructions for use...

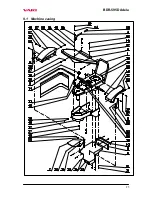

Страница 7: ...BDR 595D Adela 7 LwA 2 1 8 3 4 5 6 7 11 12 9 10...

Страница 25: ...BDR 595D Adela 25 9 1 Machine casing...

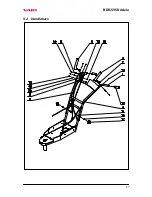

Страница 27: ...BDR 595D Adela 27 9 2 Handlebars...

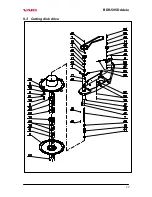

Страница 29: ...BDR 595D Adela 29 9 3 Cutting disk drive...

Страница 31: ...BDR 595D Adela 31 9 4 Wheel drive...

Страница 33: ...BDR 595D Adela 33 9 5 Gearbox...