14

Other Maintenance:

•

Should only be carried out by a qualified

electrician.

•

The steam cylinder should be drained prior to

carrying out any maintenance in the steam section

– This must be done prior to isolating the electrical

supply, i.e. before removing the front access panel.

•

The unit should be isolated from the electrical

supply before any cover or access panel is

removed.

2.2

Service and Maintenance

As the operation of the Vapac is entirely automatic, it

normally requires no attention on a day-to-day basis.

General cleaning and maintenance of the component parts

of the Vapac are recommended at intervals of about one

year, but this is largely dependent upon the frequency of its

use and the quality of the water supply. Where the Vapac is

part of an air-conditioning system being serviced regularly,

the Vapac should be inspected at the same time.

2.2.1

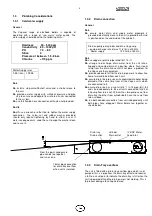

Feed Valve with Strainer

The nylon bodied solenoid valve incorporates a small nylon

strainer which is a push fit in the 3/4" inlet of the valve. With

a new plumbing installation, residual loose solid material in

the pipework could partially block the strainer after start-up.

If for this or any other reason a restriction of the water flow is

suspected (outside of supply pressure considerations), it

would be possible to clean the strainer as follows:-

Turn off the water supply to the Unit.

Undo the nylon nut connecting the

flexible connection to the valve

inlet .

The strainer can be removed using

‘long-nosed’ pliers to grip the centre

flange provided on the strainer for

this purpose.

Withdraw the strainer.

Wash and replace it.

Reconnect and turn on water

supply.

Reconnect electrical supply to allow

unit to operate.

Note: Always replace the strainer

after cleaning as it is required to

prevent material lodging in the

valve seat or blocking the small

flow control restrictor which is fitted

in the valve.

2.2.2

Drain Pump

The pump should be inspected and cleaned regularly. It

is recommended that this is done at each cylinder

exchange especially in hard water areas. Failure to keep

the pump clear and operational will result in reduced

cylinder life.

To remove the pump for maintenance purposes proceed

as follows:

•

Depress and hold the manual drain switch to

empty the cylinder. The pump sound changes

distinctly when the cylinder is empty. When this

occurs release the switch.

•

Disconnect unit electrical supply and follow the

steam section removal instructions. Once the

steam section has been removed, the pump

can be removed.

•

Ease the pump body away from the cylinder,

sliding it fully off its base plate and release the

connecting tube.. As the pump inlet is

withdrawn from its ‘O’ ring connection, some

hot water may be released, so care should be

taken.

•

To dismantle and re-assemble pump refer to

the diagram below.

•

In operation the stainless steel shaft remains

stationary while the rotor and impeller rotate on

it. Remove all scale build-up on the shaft so

that the impeller can rotate freely.

•

Ensure that the ‘O’ ring seal is correctly

positioned when fitting the inlet housing to the

main pump body.

When re-assembling, make

sure the brass spinner is replaced on the

shaft in front of the impeller.

A smear of

multipurpose grease should be applied to the

‘O’ ring so that the impeller housing can be

rotated into position without distorting the ‘O’

ring underneath it and so maintain the water

seal.

The steam section should be refitted by following the

removal instructions in reverse order, reversing all

instructions.

Steam and Condensate Hoses

The hoses used with and in the Vapac should be inspected

at the normal service visits as part of normal maintenance.

At the first signs of deterioration, a hose should be removed

and replaced.

Valve with flow

restrictor

3/4 Nylon nut with washer as

part of flexible connector

Strainer

Shaft

‘O’

Ring

Rotor

Impeller

Spinner

Содержание VapaNet LFE Series

Страница 19: ...19 3 3 Facia Label symbols 1 ...

Страница 21: ...21 ...