12

2.0

Start-Up / Operation

2.0.1

Start-up check list

a)

Water supply and Drain Connections

:

These should be connected as indicated

under Plumbing and in accordance with the

relevant local regulations. An isolation valve

should be adjacent to the unit. The

connecting

metal

plumbing

must

be

grounded close to the unit.

b)

Steam Line:

This must be connected

according to the installation instructions with

adequate slope and support.

c)

Power supply:

Wiring to the Vapanet unit

should be by a qualified electrician and

comply with the relevant regulations using

appropriately sized cable and cable glands,

with disconnect and fuses to suit the

maximum fuse rating of the unit at the supply

Voltage. The disconnect/fuses should be

adjacent to the unit or within easy reach and

readily accessible.

d)

Control Connections:

Ensure the control

signal and security circuit are correctly

connected

according

to

the

relevant

instructions/diagrams.

e)

VAPANET

24v

Control

Circuit

Transformer:

The

standard

24V

transformer used in the units has primary

winding for 200V, 220/240V, 380V, 415V, &

440v 50/60Hz connection derived from the

local electrical supply.

Note: 60Hz connection must be specified

with order as 230V 60Hz pump is required.

f)

The maximum output & kW rating of the unit

is determined by a Current Set Plug. It is

therefore possible to down rate units to any

output, down to approximately 50% of the full

rated output. (Contact Vapac for further

details)

g)

Unit Configuration Plug (U.C.P.) sets the

maximum current level for the unit. It is fitted

directly onto the control P.C.B.

2.0.2

Start-Up Instructions

First check:

a)

That the transformer connection matches

supply Voltage.

b)

That the security circuit is closed for unit

operation.

Close the electrical access panel.

Turn on the water supply to the unit.

Close disconnect/circuit breaker feeding supply to the

unit.

Close the On/Off switch.

2.0.3

Commissioning/Start-Up

Once the Set-Up procedure has been completed, the

unit is available to operate according to the

requirements of the control signal.

When starting with an empty cylinder, the VAPANET

programme switches in the contactor and feeds water

in until the water reaches the electrodes, and current

starts to flow. Thereafter the VAPANET system will

continuously monitor and control the conductivity by

adjusting the amount of water drained and fed into the

cylinder.

With no demand the LE unit’s user LED’s will be off.

When the demand increases and the unit is switched

on the user LED’s will flash green/amber at a rate

depending on the demand input and the actual

current drawn. The actual run current is monitored

and until the actual current has two feeds above 95 %

the LED will flash green/amber when the current is

above 95% for two consecutive feeds the LED’s will

flash red.

2.0.4

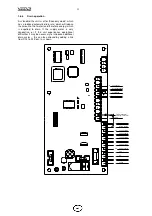

Features of VAPANET Electrode

Boiler Unit

The VAPANET system of control is designed to adjust

the function to keep the unit operating in the face of

changing water quality in the cylinder and changing

electrode condition even if, in an adverse operational

circumstance, this results in some reduction in output

while the situation exists.

Foaming protection

In particular, the VAPANET is designed to prevent the

onset of foaming and to introduce corrective drainage

to keep the unit working.

Automatic switch-off

The VAPANET PCB will stop operating in response to

extreme fault conditions identified as:

Drain Fault STOP (no drain function)

Feed Fault STOP (water not reaching cylinder)

In each case, the display will show the STOP

condition and a Help Message, the User LED’s on the

fascia will indicate the condition see table on page 20.

The STOP condition of a VAPANET PCB will be

cleared by switching the unit off and on.

THIS ACTION

SHOULD ONLY BE TAKEN ONCE THE CAUSE OF THE

PROBLEM HAS BEEN ASCERTAINED AND RECTIFIED.

2.1

Service Advice

The water hardness and the humidity demand at site will

determine the effective life of a steam cylinder. Units located

in areas with naturally soft waters will experience the longer

cylinder life, possibly upwards of 12 months in calendar

terms. With hard waters, a more frequent cylinder exchange

must be expected and cylinder exchange 2 or 3 times a year

can be the average situation. The normal scaling up of the

Vapac steam cylinder is outside the Vapac warranty.

2.1.1

Procedure for Cylinder Exchange.

A)

Remove the drain tray assembly from the

unit, as follows:-

1. With the power connected to the unit, manually

drain the unit, by depressing (and holding) the

Run/Off/Drain Switch to the momentary drain

position.

2. Disconnect the Vapac from the incoming

electrical supply by means of the external isolator

(disconnect switch). This should be “locked off” to

prevent accidental operation.

3. Remove the steam section access panel.

4. Remove the plug connection for the float

switches and drain tray condensate pump.

5. Remove the electrode connections.

6. Disconnect the drain pump.

7. Remove the steam distribution assembly by lifting

it clear of the cylinder steam outlet boss. Note it

may be necessary to rotate it as it is raised to get

it high enough to clear the boss.

Содержание VapaNet LFE Series

Страница 19: ...19 3 3 Facia Label symbols 1 ...

Страница 21: ...21 ...