Inspection and maintenance 8

0020271943_00 atmoMAG Installation and maintenance instructions

17

8.7

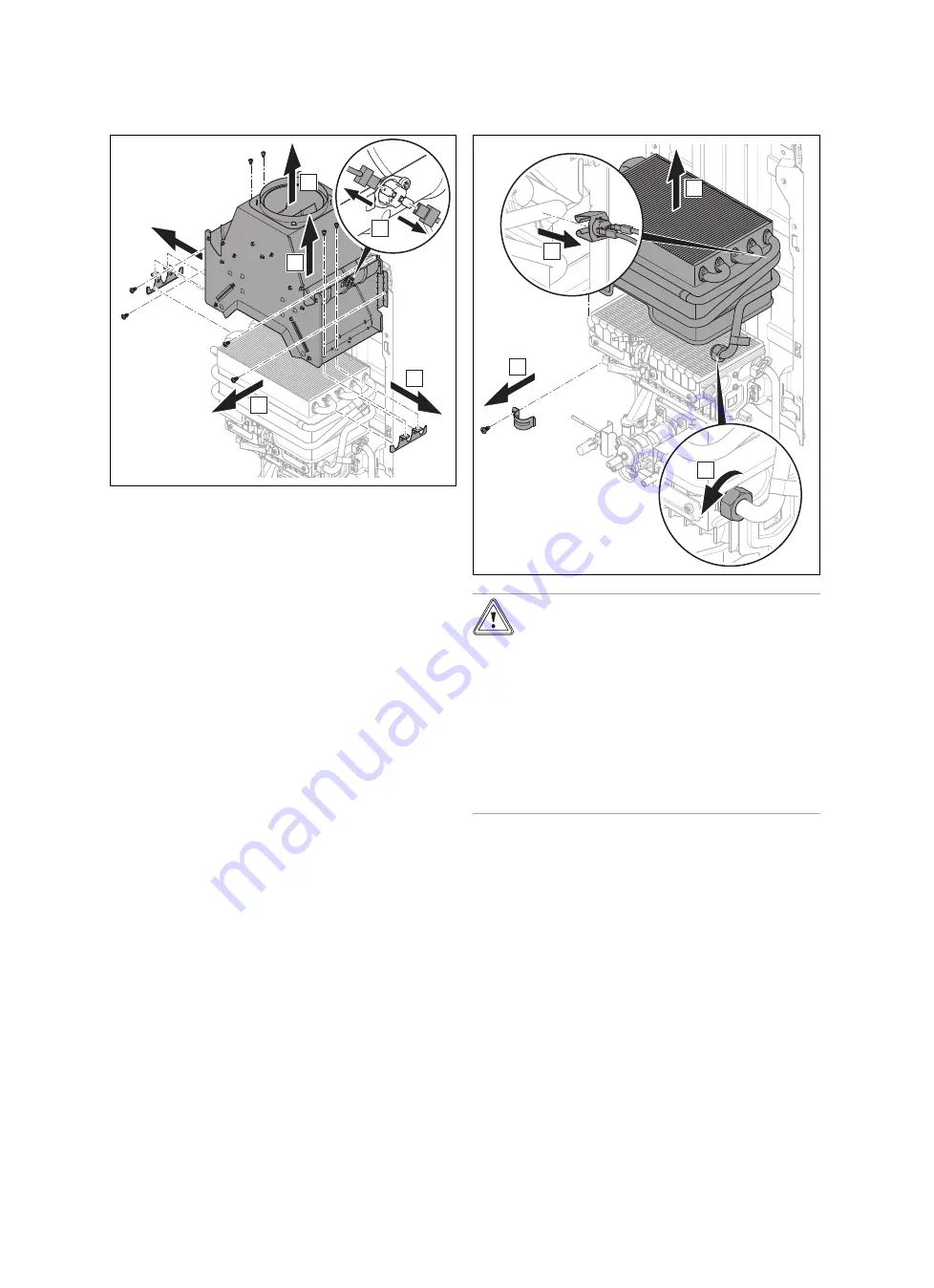

Removing the down-draught diverter

D

C

E

B

A

1.

Remove the cables from the flue gas sensor.

2.

Remove two screws each from the fixing plates on the

heat exchanger.

3.

Remove two screws each for securing the down-

draught diverter on the back panel of the product.

4.

Pull out the down-draught diverter.

8.8

Cleaning the down-draught diverter

1.

Remove the down-draught diverter. (

→

Page 17)

2.

Blow any dust and dirt out of the slits in the down-

draught diverter. Use a soft brush to remove any dust

and greasy dirt from the outside of the down-draught

diverter. Only use water if the flue gas sensor has been

removed.

8.9

Removing the heat exchanger

D

B

C

A

Caution.

Risk of material damage caused by dam-

age to the heat exchanger.

Damage that occurs when installing and re-

moving the heat exchanger leads to prema-

ture wear.

▶

When installing or removing the heat ex-

changer, ensure that it does not become

damaged or bent out of shape.

▶

Remove the heat exchanger in the spe-

cified sequence.

1.

Unscrew the union nuts from the domestic hot water

connection on the heat exchanger.

2.

Unscrew the screw from the clamp for securing the do-

mestic hot water outlet.

3.

Remove the safety cut-out that is secured using a clip

on a pipe to the right on the heat exchanger.

4.

Remove the heat exchanger.