7 Gas supply adjustments (Commissioning Part II) 7

Instructions for installation and servicing aquaPLUS VUI 362-7

30

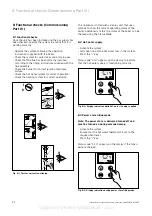

7.6 Checking the gas valve mid setting point

To ensure the most efficient operation of the boiler a

gas valve mid setting point is necessary.

This mid setting point has been factory set and

adjustment of this point is only required after

exchanging either the electronic circuit board or gas

valve or converting the boiler to another gas type.

To check the mid setting point proceed as follows.

• Turn off the boiler at the main ON/OFF control.

• Press and hold the ”+” button,,while pressing the

button turn the main ON/OFF control to the ”I” ON

position.

• Continue holding ”+” button until display starts to

alternate between the P numbers (P1,P2,P3,P11,P12

and P13).

Release ”+” button.

• Press ”+” button until ”P3 ” (mid setting point) is

shown in display.

• Press ”i” button to operate boiler at mid setting point.

• The burner pressure should now read the mid setting

point pressure for the gas type used,as detailed in

the table below.

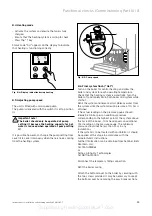

If the mid setting point pressure is incorrect it can be

adjusted as follows.

Turn off the boiler at the main ON/OFF control.

• Press and hold the ”+” button,,while pressing the

button turn the main ON/OFF control to the ”I” ON

position.

• Continue holding ”+” button until display starts to

alternate between the P numbers (P1,P2,P3,P11,P12

and P13).

Release ”+” button..

• Press ”+” button until ”P11 ” ((or natural gas)or "P 13"

(for LPG) is shown in display.

• Press ”i” button to operate boiler at mid setting point.

• The mid setting point burner pressure is now adjusted

by pushing the "+"button until the gauge equals the

pressure as detailed in the table below.

Note!

The "-" button has no function in this mode, if the

required pressure is exceeded during set up, this

operation should be recommenced from the

beginning.

When the pressure is correct, to save the setting to

memory, press and hold the "i"button until the display

stops flashing.

To cancel selected mode press the "i"and "+"buttons

simultaneously.

Re-check ignition and main burner pressures.After

completion of these tests tighten the sealing screw and

check all joints and test points for soundness.

Gas type

Mid setting point pressure

Natural Gas (G20)

5.3 mbar

LPG (G30/31)

15.3 mbar

Program No.

Gas type

Mid setting point

P.11

Natural Gas

5.3 mbar

(G20)

P.12

Not applicable -

for GB

P.13

LPG (G30/31)

15.3 mbar

7.7 Burner pressure and gas rate

1)

15 °C, 1013 mbar, dry

2)

The nozzles are stamped with the mark shown in this table. The

marking corresponds to the nozzle hole diameter multiplied by 100.

Gas Rate aquaPLUS

Output [kW]

Delivered Gas

10,5 12,0 16,0 18,0 20,0 24,0 28,0 30,0 33,0 36,9

Natural gas 2H

Gas rate

1)

[m

3

/h] for G20

1.3

1.4

1.9

2.2

2.4

2.8

3.3

3.5

3.9

4.3

Main burner jet mark

2)

7/120

Burner Pressure aquaPLUS

Ignition

Output [kW]

Delivered Gas

rate

10.5 12.0 16.0 18.0 20.0 24.0 28.0 30.0 33.0 36.9

Natural gas 2H

Burner pressure

1)

[mbar] for G20

1.1

1.1

1.4

2.4

2.9

3.65.0

6

.7

7.5

9.0

11.0

Main burner jet mark

2)

7/120

Setting-up program: P11

mid. setting point pressure: 5.3 mbar

L.P.G. 3+

Burner pressure

1)

[mbar] for G30

2.8

2.8

3.5

5.9

7.3

8.9 12.616

.8 19.1 22.9 28.2

Main burner jet mark

2)

7/072

Burner pressure

1)

[mbar] for G31

3.5

3.5

4.4

7.3

9.1

11.1

15.620.8 23.7 28.3 34.9

S

etting-up program: P13

mid. setting point pressure: 15.3 mbar

Supplied by HeatingSpares247.com