Electrical installation 5

0020188110_03 recoVAIR Installation and maintenance instructions

11

–

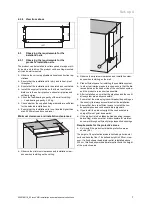

Drip distance:

≥

20 mm

3.

Fill the condensate siphon/dry siphon with water.

4.4.5

Connecting the pipelines

1.

Check the pipelines for coarse dirt.

Coarse dirt: Available

▶

Clean the pipelines.

2.

Route the pipelines in accordance with the manufac-

turer's specifications and applicable regulations for the

product.

–

Diameter of pipelines:

≥

150 mm

–

Installing the exit air lines: Continuous downward

gradient to the product with condensate drain pipe-

work at the lowest point (special accessory (elbow

with condensate discharge))

3.

Install the silencer in the supply, exit and outside air

lines.

4.

Insulate all of the pipelines in accordance with the ap-

plicable regulations.

Note

Supply and exhaust air lines too, when rout-

ing through unheated rooms.

5.

Seal the outside and exit air lines so that they are va-

pour-diffusion-tight.

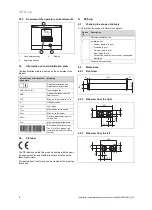

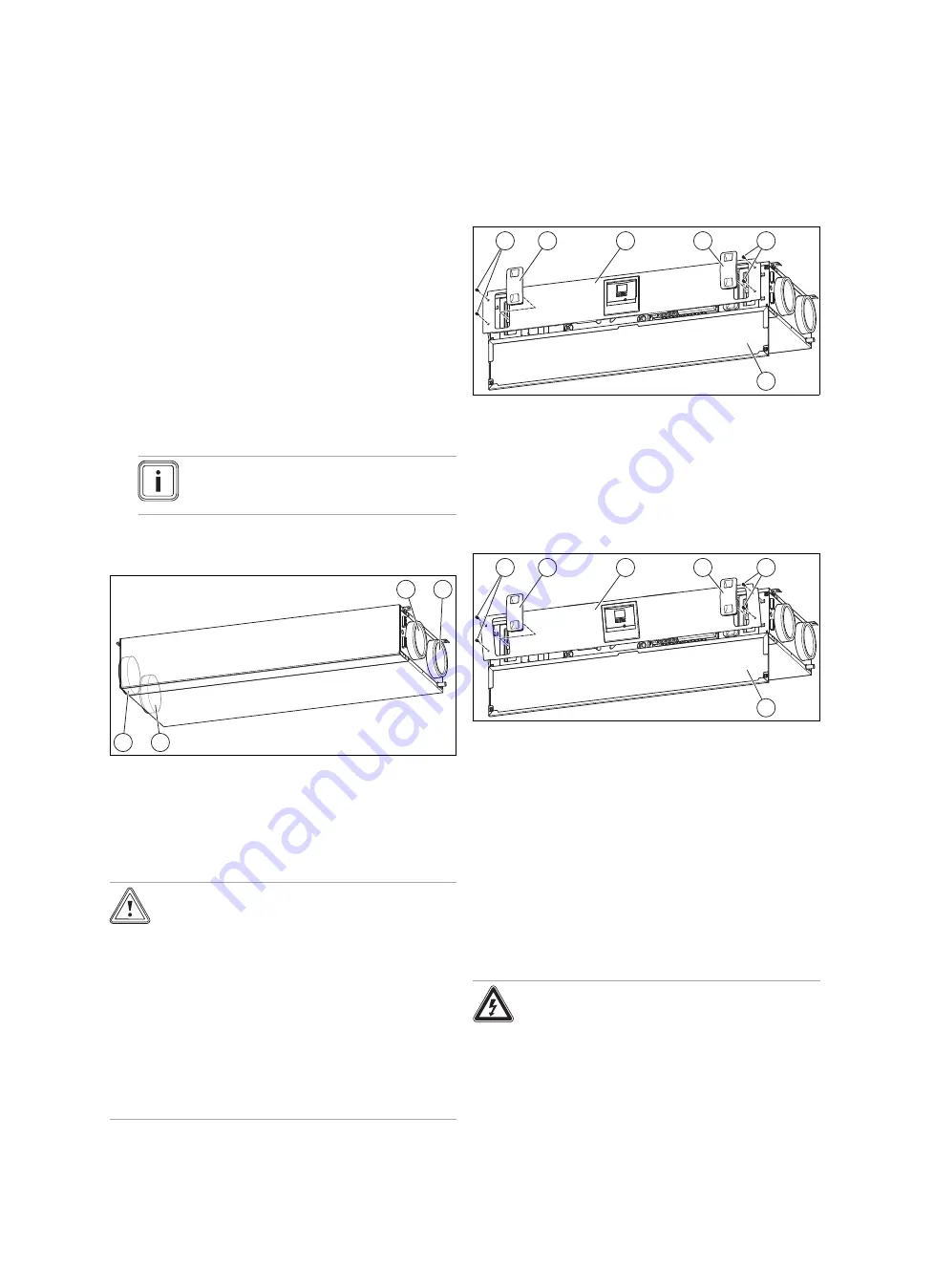

3

4

1

2

1

Outside air connection

(R variant)

2

Exit air connection (R

variant)

3

Supply air connection

(R variant)

4

Exhaust air connection

(R variant)

6.

Remove the sealing caps from the product connections.

7.

Connect the pipelines to the product.

Caution.

Risk of material damage caused by a

missing seal.

If the pipelines are not connected to the

product in way that is vapour-diffusion-tight,

condensate may form and damage the

product.

▶

Seal all of the connections for the

pipelines to each other and on the

product, so that they are vapour-diffusion-

tight.

▶

Use suitable accessories and sealant.

8.

Seal all of the product connections so that they are va-

pour-diffusion-tight.

–

Suitable vapour-diffusion-tight adhesive tape

4.5

Opening/closing the product

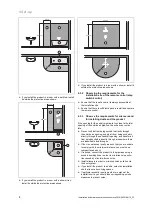

4.5.1

Opening the product

1

1

2

3

2

4

1.

Open the front flap

(4)

.

2.

Pull out both of the filter plugs

(2)

.

3.

Open all the turn locks

(1)

on the operator control

screen.

–

Quarter turn to the left

4.

Remove the operator control screen

(3)

.

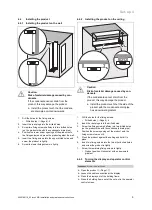

4.5.2

Closing the product

1

1

2

3

2

4

1.

Place the operator control screen

(3)

onto the product

by placing the "uneven" edge of the operator control

screen onto the corresponding cut-outs.

2.

Press the operator control screen onto the product and

screw the turn locks

(1)

closed.

–

Quarter turn to the right

3.

Push in both filter plugs

(2)

.

4.

Close the front flap

(4)

.

5

Electrical installation

Only qualified electricians may carry out the electrical install-

ation.

Danger!

Risk of death from live connections

(230 V)!

Risk of death from electric shock when work-

ing on live connections (230 V).

▶

Before carrying out any work on the

product, pull the product's mains plug

out of the earthed plug socket or use the