18

3

Please read these instructions carefully before starting installation and keep for

future reference.

Remove all packaging and check the product for missing parts or damage before

starting installation.

Any alterations made to this product and fittings may infringe water regulations and

will invalidate the guarantee.

The installation must comply with all Local/National Water Supply Authority

Regulations/Byelaws and Building and Plumbing Regulations.

To be installed in accordance with BS EN806.

We strongly recommend that you use a qualified and registered plumber.

General installation

Important - please read

This fitting is a mixing device and therefore water supplies should be reasonably

balanced.

When installed, the fitting must comply with the requirements of the Water Supply

(Water Fittings) Regulations 1999 and Scottish Byelaws 2004.

For further information, contact the Water Regulations department of your local water

supplier (see the WRAS website www.wras.co.uk for details) or the Water Regulations

Advisory Scheme by email (info

@

wras.co.uk) or telephone: 01495848454.

Before making any inlet pipe connections, all supply pipes MUST be thoroughly flushed

to remove debris. Failure to do so could result in damage or low flow from the mixer

unit. Water Supply (Water Fittings) Regulations 1999 Schedule 2 Section 13.

The fitting of isolating valves to the inlet feeds is advised for ease of maintenance.

Please take great care when installing this mixer not to damage its surface.

Please note if installing in an enclosed environment, access should be left for servicing

and maintenance. No costs relating to inadequate access can be accepted.

Operating Specifications

Operating Pressure

Minimum operating pressure

1 bar

Maximum operating pressure

5 bar

Commissioning

The valve has been factory set under balance pressures and hot water supply at 65°C.

When your specific operating conditions are significantly different from the above, the

temperature of the water may vary from the setting.

When the difference is too great, you can adjust the calibration of the valve to suit

individual requirements of the installation:

1. Check the temperature of the water being delivered from the outlet with a

thermometer.

Note:

temperature readings should be taken at normal flow rate after allowing for the

system to stabilise.

2. If the temperature is not 38°C proceed to reset the calibration as follows.

Remove the handle.

Ensure the step on the stop ring is located at 12 o'clock.

Do not remove the plastic stop ring. Turn the spline of the thermostatic valve clockwise

to decrease the temperature and anti-clockwise to increase the temperature until 38°C

is achieved at outlet.

Note:

the sensing part of the thermometer probe must be fully submerged in the water

that is to be tested.

Replace the handle making sure that the pin is against the step.

Once the handle has been attached ensure the temperature does not exceed 46°C when

turned entirely anti-clockwise.

Your valve setting is now commissioned.

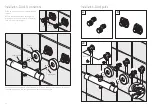

Step

Cover

Screw

Stop ring

Pin

Inside handle