10

17/05/2016

RD 300-400S/C

1. Setup

Press Setup to access:

Calibration of delivered seed

Fertiliser

BioDrill (option)

Radar

General (Basic settings)

Tramlining (Setting desired tramlining

programme).

Alarm settings

Workstation I/O (service menu)

1a. Calibration

If you access any of the calibration menus, a pop up will appear:

NOTE!

Feed output stops if you access any of these menus!

Select Yes

Before calibration is performed, the bottom flaps and sliding hatches must be

correctly adjusted. If small-sized seed needs sowing, normal rollers must also be

disengaged. See attachment 1.

1.

Enter the required seed application rate (

kg/ha)

2.

Enter the required reduction/decrease of

variable application rate in %.

3.

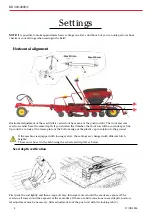

Mount the calibration trays and reverse the

calibration flaps on the lever on the side of the

seed hopper (see image on next page).