95-8401

6

2.1

to 20 ma output corresponds to levels from 0 to full

scale. If a system fault is detected, the output drops

to less than 1.0 ma. The current output can be

calibrated in the field to ensure maximum accuracy.

(Refer to the “Calibration” section of this manual for

details.)

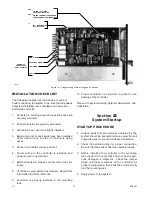

PROGRAMMING OPTIONS

(PREMIUM MODEL ONLY)

Each of the four relays is field selectable for either

normally open or normally closed contacts using

jumper plugs located on the printed circuit board

inside the controller. (See Table 3.)

The alarm relays are also switch programmable for

either normally energized or normally de-energized

operation (programmable as a group only, not

individually) . The fault relay is normally energized.

The low and auxiliary alarm relays are programmable

for either latching or non-latching operation. The

high alarm relay is always latching and the Fault

relay is non-latching. Latching relays are reset using

either the RESET pushbutton on the front panel of the

controller or an external reset switch.

The 4 to 20 ma circuit is selectable for isolated or

non-isolated operation.

Automatic Diagnostics and Fault Identification

The microprocessor based controller features self-

testing circuitry that continuously checks for problems

that could prevent proper system response. When

power is applied, the microprocessor automatically

tests memory. In the Normal operating mode, it

continuously monitors the input signal from the

sensor/transmitter to ensure proper functioning. In

addition, a “watchdog” timer is maintained to ensure

that the program is running correctly. If a fault should

occur:

— The FAULT LED flashes.

— The digital display identifies the nature of the fault

using an alpha-numeric code. Refer to Table 4 for

an interpretation of the codes.

— The normally energized Fault output is de-ener-

gized.

— The dc current output drops to less than 1 ma.

NOTE

The fault code will be shown for about 2 seconds

out of every 5 seconds. The gas concentration at

the sensor will be displayed during the remaining

time. If more than one fault should occur, the

highest priority fault will be displayed. (Table 4 lists

the faults in order of priority.)

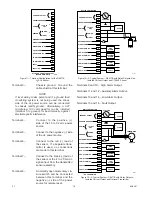

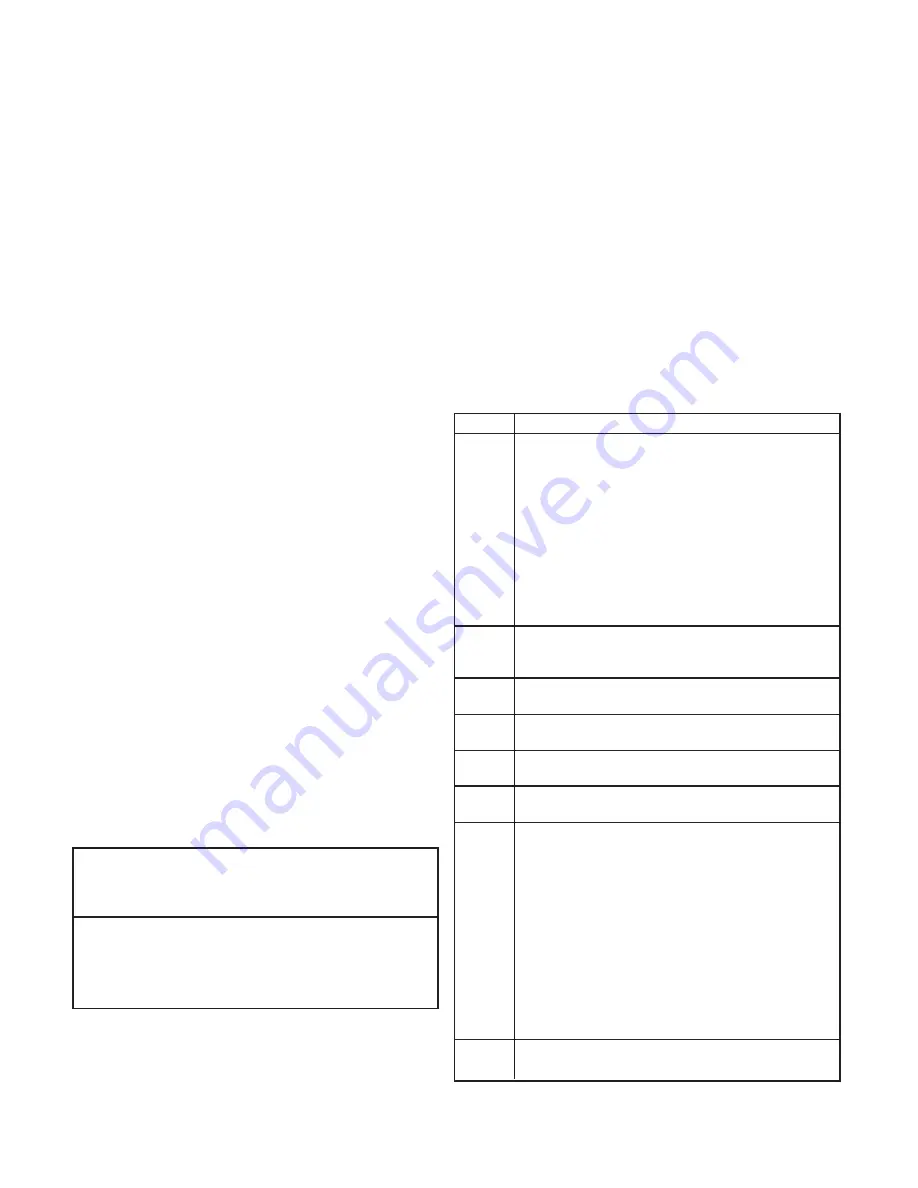

Table 3—Selectable Relay Options

Relay

Selectable

Selectable

Selectable

Normally

Normally

Latch/

Open/Closed

Energized/

Non-Latch

De-Energized

Low Y Y1

Y1

High Y Y1

N2

Auxiliary Y

Y1

Y1

Fault Y N3

N4

Y = Yes

N = No

1Selectable as a group, not individually 2Latching only

3Normally energized only

4No latching option

Table 4—System Status Codes

Status Condition

F9X

Initialization failure. (Subcodes are as follows.)

F91 EPROM

sumcheck

failure.

F92

System failure during startup - current too high or

too low.

F93 Watchdog

timer

failure.

F94 RAM

failure.

F95

Internal 5 volt power supply failure during startup.

F96

External 24 volt power supply failure during startup.

F97

Controller type invalid. Error in data from RAM.

F98

Watchdog timer reset the controller.

F70

External reset button has been activated for 15

seconds or longer. Self-clearing when button is

released.

F60

External 24 vdc power input is not in the 18 to 32

vdc range.

F50

Internal 5 volt power supply is not in the 4.75 to

5.25 volt range.

F40

Sensor fault (after startup). Input is above 35 ma

or below 2 ma.

F30

Negative zero drift. Sensor input is –9% full scale

or lower.

F2X

Calibration error. (Subcodes are as follows.)

F20

General calibration fault, or calibration aborted due

to a higher priority fault.

F21

Time ran out while waiting for the user to apply gas

to the sensor.

F22

Sensor input is too low. The sensor cannot

generate enough offset to get an accurate

calibration. Replace sensor.

F23

Sensor is too sensitive for the controller to read

100% full scale. Replace sensor.

F24

Zero gas level too high, or sensor zero input over

limit.

F10

Sensor reaching end of life. Consider replacing the

sensor within the next two calibration periods.