95-8401

18

2.1

the auxiliary alarm setpoint. Press the appropriate

button to obtain the desired reading on the digital

display.

5. When no changes have been made for 5 sec-

onds, the Auxiliary LED goes out, the CAL LED

blinks, and the digital display indicates the cali-

bration gas concentration. Press the appropriate

button to change the calibration gas concentra-

tion as required.

6. When no changes have been made for 5 sec-

onds, the controller automatically returns to the

Normal operating mode.

7. Record the new values for future reference.

NOTE

The alarm setpoints, calibration gas concentration,

and calibration data are stored in non-volatile

memory and are retained in the event of a power

loss. However, if power is interrupted while

performing the Setpoint Adjustment or Calibration

procedure, the entire procedure must be repeated

when power is restored.

CALIBRATION

Various factors affect the time interval between

periodic recalibrations. Exposure to certain

contaminants in the air, accumulation of contaminants

on the filter, or an extended period of normal

operation can cause changes in sensitivity. Since

each application is different, the length of time

between regularly scheduled recalibrations can

vary from one installation to the next. In general, the

more frequently a system is checked, the greater the

reliability. Calibration

must

be performed:

— When a new system is initially put into service

— When the sensing element is replaced

— If a transmitter or controller used in conjunction with

the sensor is replaced

— When the hydrophobic filter is cleaned or replaced.

The following calibration schedule is recommended

when placing a new sensor into operation and will

ensure reliable operation in most applications:

1. One hour after power-up

2. One

week

later

3. Every 30 days thereafter, or as determined by the

needs of the specific application.

IMPORTANT

To ensure adequate protection, the H

2

S detection

system must be calibrated on a regularly

scheduled basis.

Loss of sensitivity can be caused by various fac-

tors. One common cause is by clogging of the

hydrophobic filter by dirt, oil, paint, etc. Problems

of this nature will not be detected by the system’s

diagnostic circuitry. While performing detec-

tor calibration, the operator should examine the

hydrophobic filter of the sensor. If it cannot be

properly cleaned, it should be replaced.

The detector must be calibrated using hydrogen

sulfide mixed with either air or nitrogen. For best

results, a calibration gas concentration equal

to the high alarm setpoint or 50% of full scale is

recommended.

NOTE

If the sensing element is being replaced, refer to

the “Sensing Element Replacement” section (under

“Maintenance”) in this manual for information

regarding replacement and calibration of the

sensor.

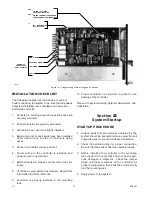

CALIBRATION PROCEDURE

The H

2

S detection system can be calibrated using

either of two methods:

1.

Transmitter calibration (if a transmitter is

used).

This method of calibration can be per-

formed by one person. All adjustments are made

at the transmitter. Calibration of certain transmit-

ter models requires removing the enclosure cover,

therefore, the hazardous area must be de-classi-

fi ed.

When transmitter calibration is performed, an

initial calibration of the controller must be per-

formed in addition to the transmitter calibration.

This calibration of the controller is not the same

as “2. Controller Calibration” described below.

It involves setting factory default calibration val-

ues in the controller that will ensure accuracy

when used in conjunction with a properly cali-

brated transmitter. Since these default values do

not change, the procedure does not need to be

repeated with subsequent transmitter recalibra-

tions. This controller calibration is accomplished

by momentarily entering the Sensor Replacement

mode. Upon entering the Sensor Replacement

mode, the controller automatically sets the fac-

tory default controller calibration values. (Follow

the procedure described in the “Setting Controller

Default Values” section.)