www.uscutter.com

425.481.3555

20

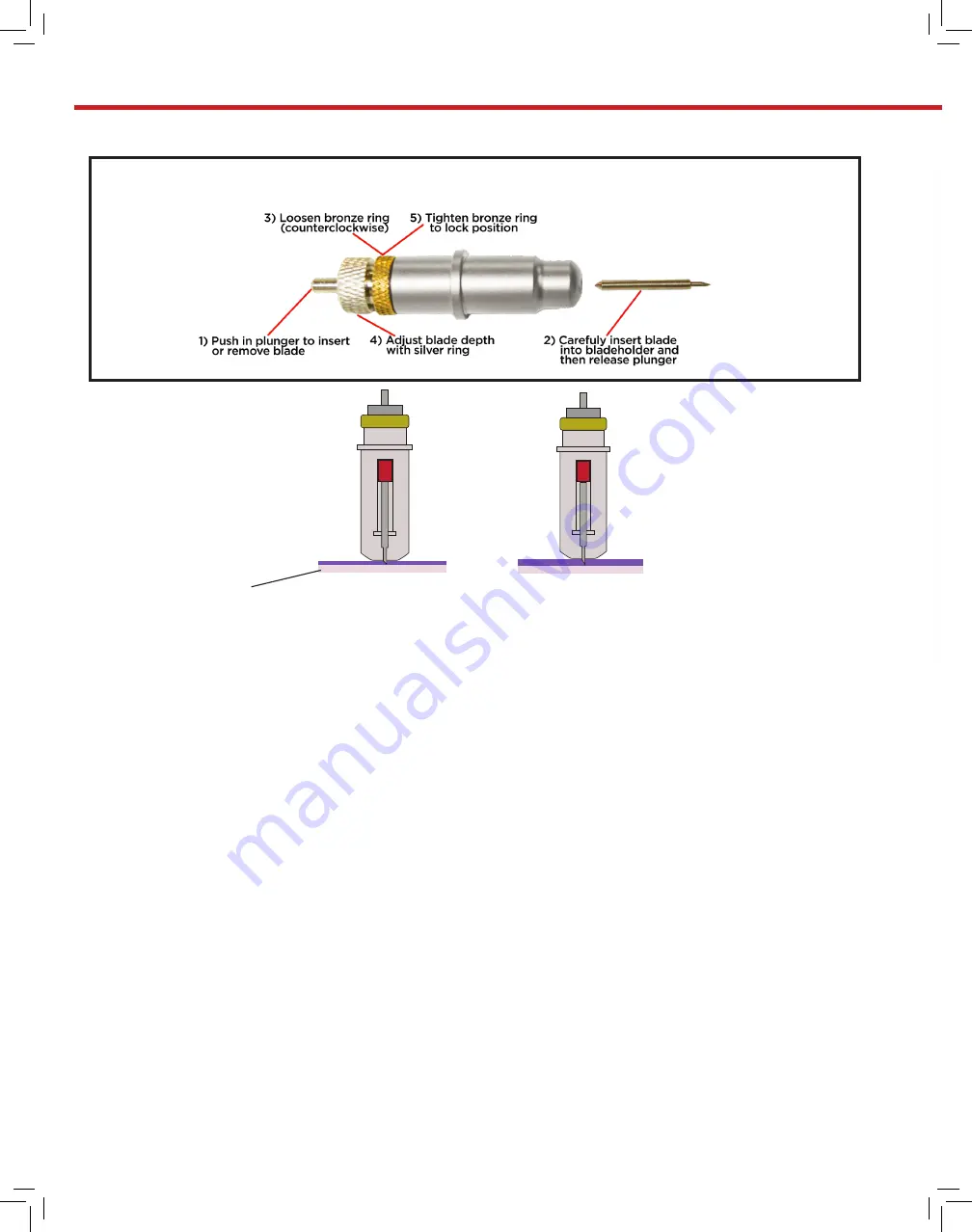

Blade Set Up

Use 45 degree blade for

most common uses

Use 60 degree blade for

thicker materials

Set blade depth to cut only

the material not the backer

BLADE SETUP

TIPS FOR GETTING OPTIMAL RESULTS

• Use a short blade depth. You only need to extend the blade 1/2 the thickness of a credit card. New users tend to ex-

pose too much blade. The idea is to cut through only the top layer of the vinyl and to leave the backing layer with only

minimal scratches. This allows you to weed the top layer off the backing easily. If corners or small detail do not cut all the

way through, consider increasing the force before extending the blade depth. If you can feel cut lines on the backer un-

derneatth the vinyl, blade depth should be reduced. You only need to extend the blade depth or use the 60 degree (blue

tip) blade for thicker materials.

• Set a safe and reliable speed.

A good starting value for speed is 300

. Once you have accumulated experience with the

material you are cutting and production time becomes a factor, you can look to increase the speed. Also, intricate jobs

typically require lower speeds.

• Set the correct force.

A good starting value for force is 70

, then you can adjust force up or down depending on how

thick/dense the material is to be cut. With test material in place, use the the Test Cut icon on the cutter’s main screen to

cut a small square in your test material to see that it cuts all the way through and can be weeded easily

• Align the pinch rollers so that they are under the guide arrows. The pinch rollers must align with the gritted sections on

the bottom roller.

• A cutting mat (optional, purchased separately) can be used when cutting materials that do not have their own back-

ing. Place your material on the cutting mat so that the pinch rollers roll on the mat, not the material. Move unused pinch

rollers out of the way so they don’t touch the parts of the material being cut. Use a brayer roller to flatten your material

on the sticky part of the cutting mat or tape the edges of thicker materials to the cutting mat. For wider jobs, it some-

times cannot be avoided and the pinch rollers will need to roll over areas of the material being cut. Typically this is not a

problem.

• When cutting long pieces of material it is important to carefully position the material so that it is completely straight

and doesn’t drift to one side when cutting.

Содержание LaserPoint3

Страница 1: ...User Manual Assembly Instructions...

Страница 31: ...www uscutter com 425 481 3555 31...