UIS-WCB1 Installation Guide

4

Unitronics

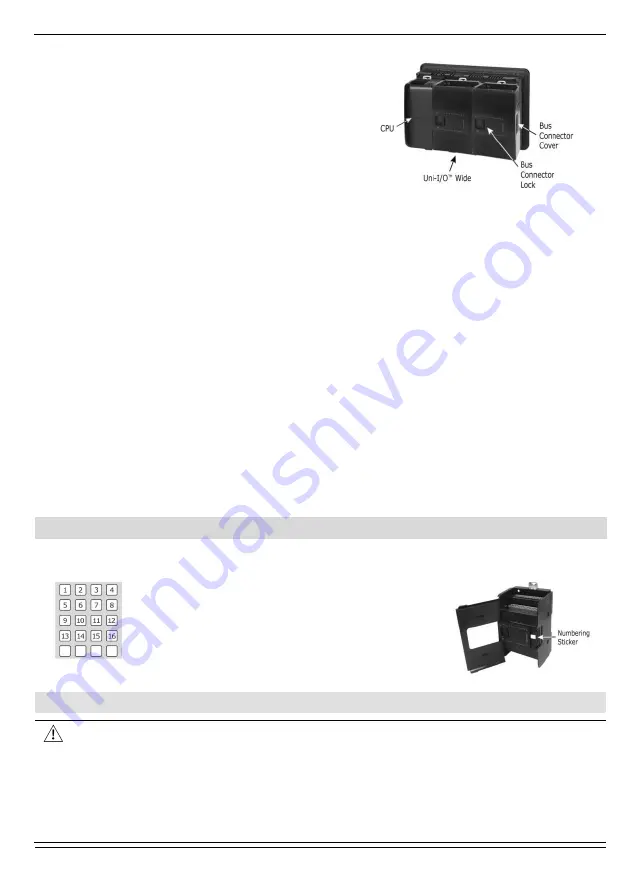

5. Slide the Bus Connector Lock all the way to

the left as shown in the accompanying figure.

6. If there is already a module located to its

right, complete the connection by sliding the

Bus Connector lock of the adjacent unit to the

left.

7. If the module is the last in the configuration,

leave the I/O bus connector covered.

Removing a Module

1. Turn off the system power.

2. Disconnect the I/O terminals (#2,3,7,8 in the diagram).

3. Disconnect the Uni-I/O™ module from the adjacent units: slide its Bus Connector Lock

to the right. If there is a unit located on its right, slide the lock of this module to the

right as well.

4. On the Uni-I/O™ module, pull the top DIN-rail clip up and the bottom clip down.

5. Open the door of the Uni-I/O™ module and hold it with two fingers as shown in the

figure on page 3; then pull it carefully from its place.

Installing Uni-I/O™ modules onto a DIN-rail

To mount modules onto a DIN-rail, follow steps 1-7 in Installing a Uni-I/O™ Module onto a

UniStream™ HMI Panel on page 3.

In order to connect the modules to a UniStream™ controller, you must use a Local

Expansion Kit.

These kits are available with and without power supplies, and with cables of varying

lengths. For complete information, please refer to the installation guide of the relevant

Local Expansion Kit.

Numbering Modules

You can number modules for reference purposes. A set of 20 stickers is provided with

every CPU-for-Panel; use these stickers to number the modules.

The set contains numbered and blank

stickers as shown in the figure to the left.

Place them on the modules as shown in the

figure to the right.

Wiring

This equipment is designed to operate only at SELV/PELV/Class 2/Limited Power

environments.

All power supplies in the system must include double insulation. Power supply

outputs must be rated as SELV/PELV/Class 2/Limited Power.

Do not connect either the ‘Neutral’ or ‘Line’ signal of the 110/220VAC to device’s 0V

point.

Do not touch live wires.