Revision date: 23 09 2014

Page 19 of 32

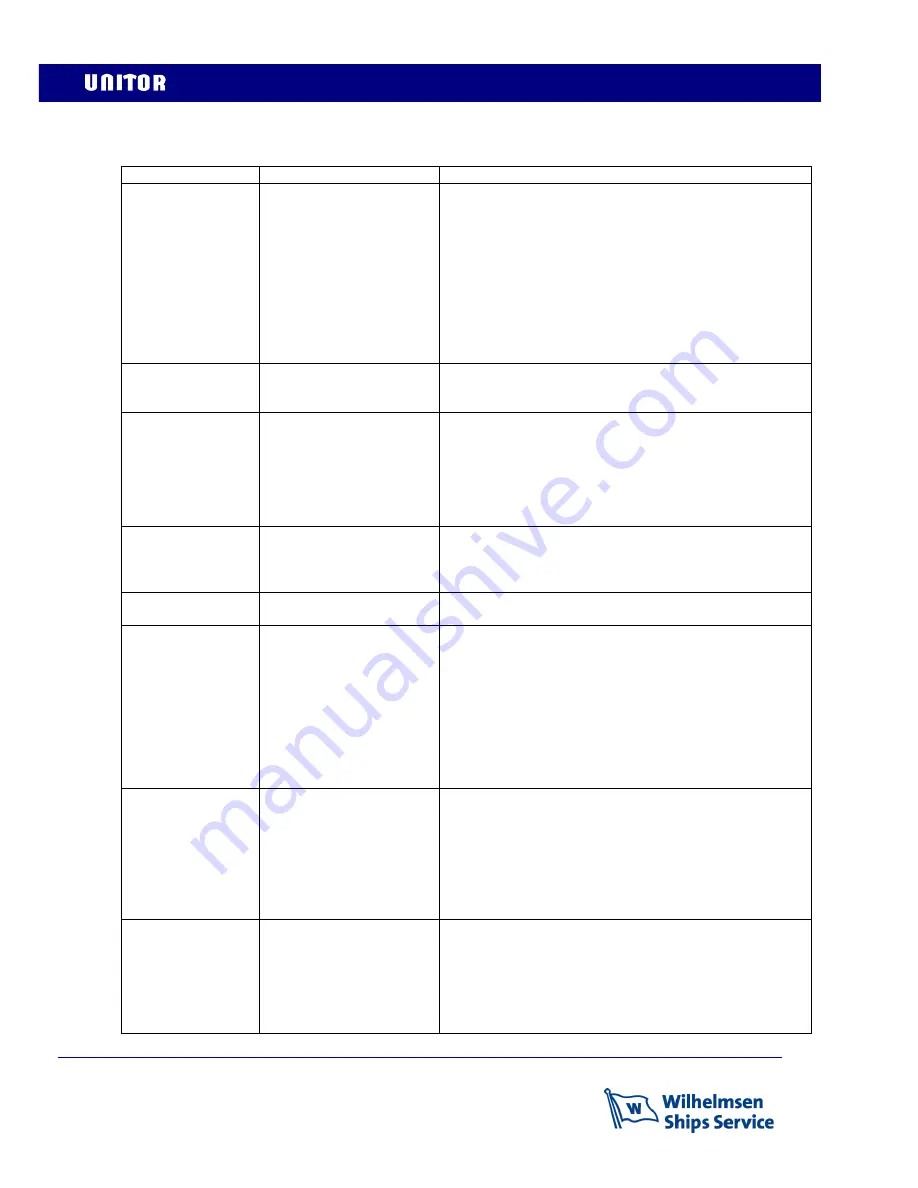

PROBLEM

CAUSE

SOLUTION

No output voltage

Check for a short circuit at

the DINSE plug with a

diode tester. A short

circuit may be caused by :

− damaged transil on the

snubber board;

− damaged diodes;

− damaged inverter;

− The inductive value of

the Power Transformer is

nill.

Unplug the machine. Remove the snubber board:

• check with a diode tester the status of the transil on the

snubber board (picture 2);

• check with a diode tester the status of the diodes;

• check the status of the power board (picture 4);

• The Power Transformer must be replaced.

Primary fuses blow

Settings have been set to

demand higher power

than available

Decrease the welding current / wire speed / voltage

settings

The welding is not

optimal.

− Spattering during

welding.

− Porosity in the deposit.

− Too narrow welding

seam (“dry arc”).

− Too wide welding seam

(“too hot weldpool”)

• Make sure welding polarity is correct.

• Decrease the voltage and check the gas emission from

the torch.

• Increase the wire speed and/or voltage.

• Decrease the wire speed and/or voltage.

The machine stops

welding and emits

an acoustic signal

(sound alarm).

The maximum current that

can be supplied by the

machine has been

exceeded

Decrease the value of the welding parameters.

Non optimal wire

welding start.

Spattering and crackeling

occurs on starting.

Decrease the wire speed setting or increase voltage

setting

No gas from the

solenoid valve

− Excessive gas

pressure.

− Damaged solenoid

valve wiring.

− The solenoid valve

control relay on the front

panel is damaged.

− Solenoid valve is

damaged

• Reduce gas flow setting.

• Unplug the machine, If break in a circuit, single out the

break and repair it. Make sure that the wiring contacts

are correctly inserted in the connectors.

• The logic front panel (pos 11) must be replaced.

• Should the operations carried out not have a positive

outcome, replace the solenoid valve (pos 35)..

Should the operations carried out not have a positive

outcome, try to replace the Toroidal Transformer (pos

21).

The torch button

does not work

− The amphenol board

(0042) cable is broken.

− The cable between the

euro connector and the

connector on front

panel.is broken

− The logic front panel

(pos 11) is damaged.

• The amphenol cable must be replaced.

• Check the connection between the Euro-connector and

pin 1/2 of the Amphenol connector.

- Then check the connection between the amphenol

connector and the motor board and between motor

board and front panel.

• The front panel must be replaced

The machine

always welds at

maximum current.

− The front panel is

damaged..

− The power board is

damaged.

− The shunt wires are

damaged or not correctly

inserted

Unplug the machine:

• The front panel must be replaced.

• The power board must be replaced.

• Connect the cables, or if damaged, replace them.