CAUTION

GASES THAT ARE DRIVEN FROM FRESH

COAL MUST BE BURNED OR THEY WILL

ACCUMULATE AND EXPLODE. NEVER

SMOTHER A FIRE WHEN ADDING FRESH

COAL.

CAUTION

DO NOT OPERATE WITH THE FEED AND/OR

ASH DOOR OPEN. THIS FURNACE IS DE-

SIGNED FOR THERMOSTATIC OPERATION.

OPERATION WITH ANY OF THESE DOORS

OPEN WILL OVERHEAT AND DAMAGE THE

FURNACE.

CAUTION

NEVER USE GASOLINE, GASOLINE-TYPE

LANTERN FUEL, KEROSENE, CHARCOAL

LIGHTER FLUID, OR FLAMMABLE LIQUIDS

TO START OR "FRESHEN UP" A FIRE IN THE

FURNACE.

WARNING

NEVER STORE FLAMMABLE LIQUIDS, ES-

PECIALLY GASOLINE, IN THE VICINITY OF

THE FURNACE.

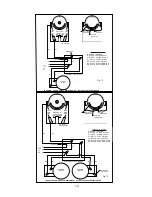

ADJUSTING BLOWER LIMIT CONTROL SET-

TINGS.

The temperature in the plenum of the warm air

furnace at which the blower turns on or turns off,

is controlled by the setting of the pointers in the

blower limit control. These pointers may be ad-

justed through their entire range of settings to

achieve the desired warm air output from furnace.

(See Fig. 16 below)

Operating Instructions

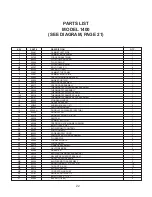

FUEL, Model 1300

Egg size (1-3/16" or larger) bituminous coal

for residential furnaces, or any of the specially

packed fireplace coals can be used. Coal with a

low ash content (2% to 6%) is recommended.

FUEL, Model 1400

Hardwood, 18" to 26" should be split and air dried

(seasoned) for 6 months.

LIGHTING

1.

2.

3.

4.

5.

Set the thermostat on "HIGH" for maximum

draft.

Open the feed door and place paper and

kindling on the grate for starting the fire.

Light the fire and close the feed door.

Add wood or about 15 lbs. of coal (depending

on which model) after fire is burning briskly.

Set thermostat for desired temperature.

"MEDIUM" setting is normally satisfactory.

Set higher or lower for your comfort.

ADDING FUEL

When starting a fire, add small amounts of fuel

instead of adding large quantities of fuel. This will

give more complete combustion and less buildup

of tars or soot in the chimney.

Set thermostat to HIGH before opening feed

door.

Wood fire - Model 1400.

Add wood to a convenient level.

Coal Fire - Model 1300.

Never smother the fire when adding coal (See

Caution). Gas accumulation and a mild smoky

explosion will occur. Add fresh kindling if the

bed of coals has cooled.

Add up to 20 lbs. of coal per loading. Never add

coal above the bottom of feed door opening.

Stir the coal and watch the fire. Be sure the

new coal is burning briskly before you close

the doors and turn the thermostat down

.

Shake grates vigorously 1/2" left to right to spill

ashes into the ash pan. Do this at least once

every 12 hours of operation. Empty ash pan

regularly. Do not allow ashes to buildup to

grate as grate will warp and burnout, and you

might spill the ashes when removing the pan.

Dispose of hot ashes properly (See note 12 on

page 4).

Rotation of the handle (5 o'clock to 7 o'clock)

position will agitate coals and spill ashes into

ash pan.

It is advisable for you to get familiar with the

shaker grate operation before firing.

1.

2.

3.

a.

b.

c.

d.

e.

f.

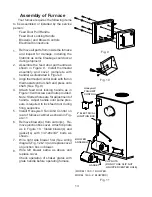

Move both pointers towards the right (counter

clockwise) - this increases the temperature

setting at which the blower will turn on and off.

Move both pointers towards the left (clock-

wise) - this decreases the temperature setting

at which the blower will turn on and off.

Move pointers away or apart from each other-

this increases the time that the blower will run

on each warm air cycle.

BLOWER FAN

"OFF" POINTER

BLOWER FAN

"ON" POINTER

BLOWER LIMIT

POINTER & STOP

17

Fig. 16

Содержание HOTBLAST 1300

Страница 30: ...NOTES 30...

Страница 31: ...NOTES 31...