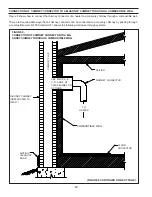

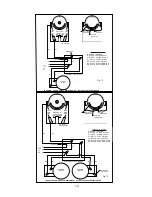

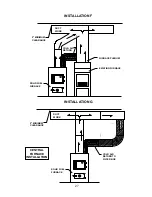

2" MIN. AIR SPACE

REQUIRED BY CODE

18" MIN.

CENTRAL

FURNACE

Figure 14

16

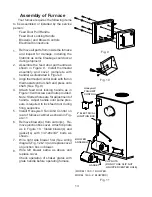

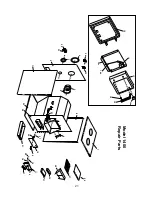

Power Failure Instructions:

Operation after loss of power--

1. Remove filter if provided

2. Do not expect to keep home at normal temperatures.

3. Do not load fuel above bottom of feed door.

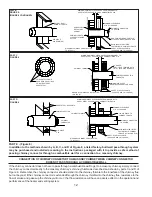

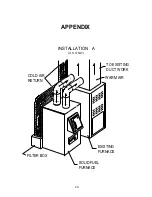

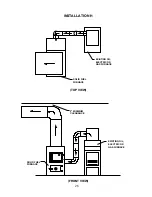

TO GAS/OIL/ELECTRIC

TRANSFORMER AND

COMBUSTION FAN OF

SOLID FUEL UNIT

H

N

POWER

SUPPLY

FURNACE

BLOWER

MOTOR

FAN

LIMIT

COMBINATION CONTROL

GAS/OIL/ELECTRIC

POWER SUPPLY

JUNCTION BOX

JUMPER IN

CAUTION!

DO NOT CONNECT

PLENUM FAN CONTROL

SWITCH ACROSS FURNACE

LIMIT CONTROL.

Figure 15

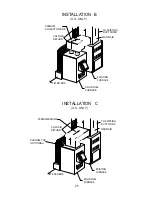

PLENUM

TO

CEILING

6" MIN.

Содержание HOTBLAST 1300

Страница 30: ...NOTES 30...

Страница 31: ...NOTES 31...