035-16626-000-E-0103

12

Unitary Products Group

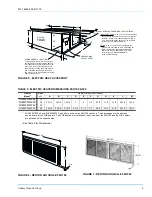

The 3” dimension must equal or exceed the negative

static pressure developed by the supply air blower. If it

does not the condensate will not drain properly and

may overflow the drain pan. The trap must be at least

2-1/2” deep to maintain a water seal under all operat-

ing conditions, especially during blower start-up.

NOTE: The unit may have to be raised off the floor to

allow enough height for the trap.

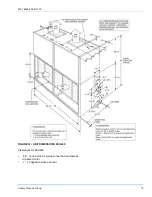

SUPPLY AIR BLOWER ADJUSTMENT

The RPM of the supply air blower will depend on the

required CFM, the unit accessories and the static resis-

tances of both the supply and the return air duct sys-

tems. With this information, the RPM for the supply air

blower can be determined from the blower perfor-

mance in Table 6.

Knowing the required blower RPM and the blower

motor HP, the settings (turns open) for the supply air

motor pulley can be determined from Table 6.

Each motor pulley has:

1. A threaded barrel with two flats (or notched

recesses 180° apart.

2. A movable flange with one set screw.

After the movable flange has been rotated to the

proper number of “turns open”, the set screw should be

tightened against the flat on the barrel to lock the mov-

able flange in place. If the pulley includes a locking

collar, the locking collar must be loosened to adjust the

setting of the movable flange.

Note the following:

1. The supply air CFM must be within the limitations

shown in Tables 7 and 8.

2. All pulleys can be adjusted in half turn increments.

3. The tension on the belt should be adjusted for a

deflection of 3/16” per foot of belt span with an

applied force of 2 to 3 pounds. This adjustment is

made by moving the blower motor mounting plate.

Refer to Figure 14. Turning the adjustment bolt (B)

moves the motor mounting plate up or down. Two

hex nuts (A have to be loosened to move the

mounting plate and retighten after the mounting

plate has been moved to the proper position.

NOTE: Never loosen the two nuts (C) (shown in Fig-

ure 14)

4. All pulleys are factory aligned.

5. All supply air motor pulleys are factory set at 3

“turns open”.

After the supply air blower motor is operating, adjust

the resistances in both the supply and the return duct

system to balance the air distribution throughout the

conditioned space. The job specification may require

that this balancing be done by someone other than the

equipment installer.

FIGURE 13 - RECOMMENDED DRAIN PIPING

5 "

2 - 1 / 2 "

P L A S T I C

E L L

S T E E L

S T U B

C O N N E C T I O N

H O S E C L A M P S

E V A P O R A T O R

C O I L

D R A I N P A N

D R A I N

P L U G

TABLE 6: SUPPLY AIR BLOWER MOTOR PULLEY

ADJUSTMENT

TURNS

OPEN

DRIVE RANGE

625-810 RPM

827-986 RPM

5

625

827

4

662

859

3

699

891

2

736

923

1

773

955

0

810

986