035-20499-001 Rev. B (1004)

Unitary Products Group

5

If a matching cooling coil is used, it may be placed directly on the fur-

nace outlet and sealed to prevent leakage. Follow the coil instructions

for installing the supply plenum. On all installations without a coil, a

removable access panel is recommended in the outlet duct such that

smoke or reflected light would be observable inside the casing to indi-

cate the presence of leaks in the heat exchanger. This access cover

shall be attached in such a manner as to prevent leaks.

RESIDENTIAL AND NON HUD MODULAR HOME

RETURN PLENUM CONNECTION

Return air may enter the furnace through the side(s) or bottom depend-

ing on the type of application. Return air may not be connected into the

rear panel of the unit. In order to achieve the airflow indicated, it is rec-

ommended those applications over 1800 CFM (57 m³/min) use return

air from two sides, one side and the bottom or bottom only. For single

return application, see data and notes on blower performance data

tables in this manual.

BOTTOM RETURN AND ATTIC INSTALLATIONS

Bottom return applications normally pull return air through a base plat-

form or return air plenum. Be sure the return platform structure or return

air plenum is suitable to support the weight of the furnace.

The furnace base is equipped with a rectangular blockoff panel that can

be removed by performing the following steps:

1.

Lay the furnace on its back.

2.

Remove the toe plate. See Figure 2.

3.

Slide the blockoff panel out and then replace the toe plate.

4.

Bend the 3/4” flanges that will be used to attach the return air ple-

num using the scribe marks in the furnace base. Refer to Figure 1

“Bottom Image Return End”.

5.

Be sure to seal the furnace to plenum connections to prevent air

leakage. Refer to Figure 1 for unit and plenum dimensions.

Attic installations must meet all minimum clearances to combustibles

and have floor support with required service accessibility.

The supply air temperature MUST NEVER exceed the Maximum

Supply Air Temperature, specified on the nameplate.

Operating the furnace above the maximum supply air temperature

will cause the heat exchanger to overheat, causing premature heat

exchanger failure. Improper duct sizing, dirty air filters, incorrect

manifold pressure, incorrect gas orifice and/or a faulty limit switch

can cause the furnace to operate above the maximum supply air

temperature. Refer to sections II and III for additional information on

correcting the problem.

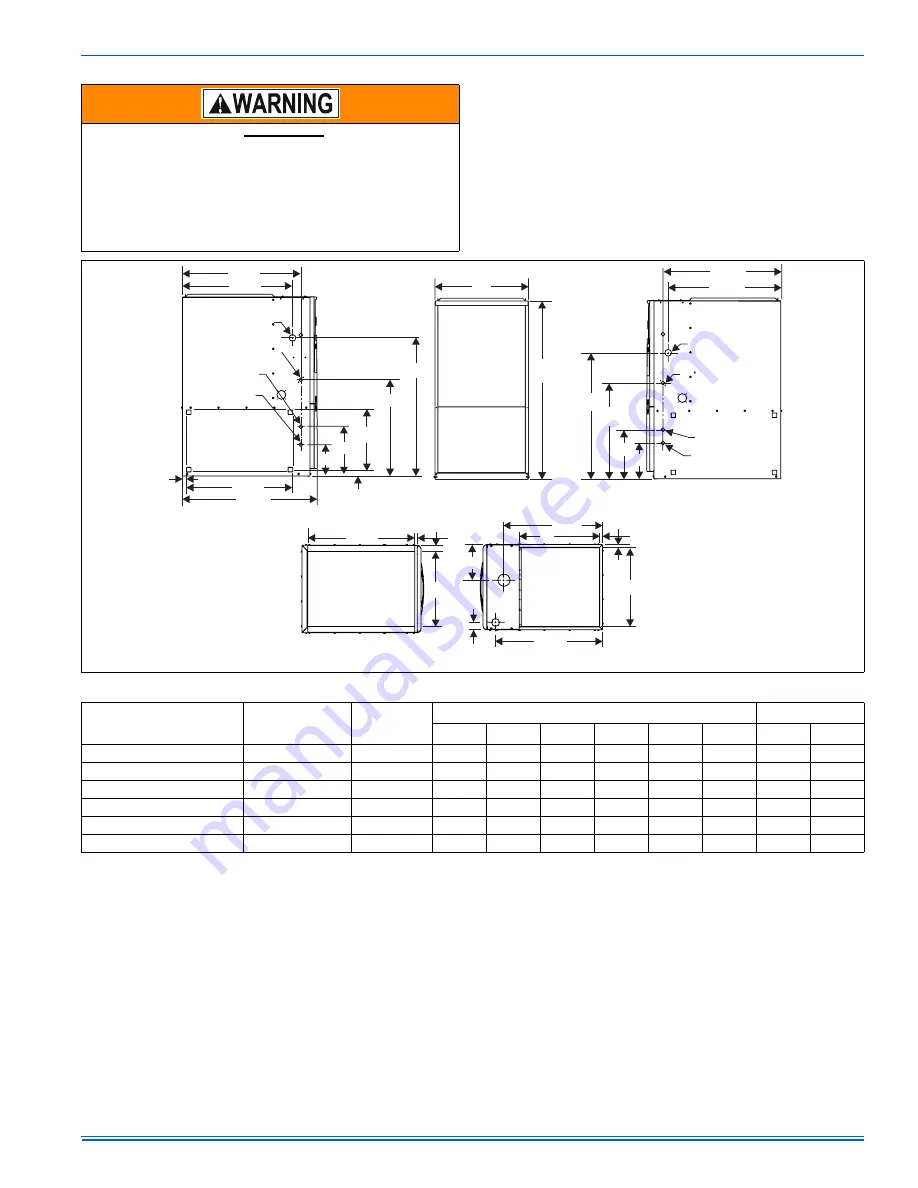

FIGURE 1:

Dimensions

30-7/8

21-1/2

13-7/8

7

11

7/8

23-3/4

7/8

30-1/8

26-1/2

24-5/8

A

40

26-1/2

25-3/8

28-3/8

21-1/2

11

8

1-1/2” GAS

PIPE ENTRY

7/8” JUNCTION

BOX HOLE

T-STAT WIRING

7/8” K.O.

CONDENSATE

DRAIN 7/8” K.O.

OPTIONAL RETURN AIR

CUT-OUT (either side)

FOR USE WITH

EXTERNAL FILTER

FRAME

LEFT SIDE

FRONT

RIGHT SIDE

26-3/4

1-3/8

1-1/4

C

24-3/8

20

5/8

5/8

B

26-1/2

1-3/4

D

BOTTOM IMAGE

RETURN END

TOP IMAGE

SUPPLY END

1-1/2” GAS

PIPE ENTRY

7/8” JUNCTION

BOX HOLE

T-STAT WIRING

7/8” K.O.

CONDENSATE

DRAIN 7/8” K.O.

BTUH (kW)

Input/Output

CFM

m

3

/min)

Cabinet

Size

Cabinet Dimension

Air Intake

A (in.)

A (cm)

B (in.)

B (cm)

C (in.)

C (cm)

D (in.)

D (cm)

40/38 (11.7/10.8)

1200 (33.98)

A

14-1/2

36.8

13-1/4

33.7

12-1/8

30.8

6-1/4

15.9

60/56 (17.8/16.4)

1200 (33.98)

B

17-1/2

44.4

16-1/4

41.3

15-1/8

38.4

8-1/2

21.6

80/75 (12.4/21.96)

1200 (33.98)

B

17-1/2

44.4

16-1/4

41.3

15-1/8

38.4

8-1/2

21.6

80/75 (23.42/21.96)

1600 (45.31)

C

21

53.3

19-3/4

50.2

18-1/2

47.0

8-7/8

22.5

100/93 (29.28/27.25)

2000 (56.63)

C

21

53.3

19-3/4

50.2

18-1/2

47.0

8-7/8

22.5

120/112 (35.14/32.80)

2000 (56.63)

D

24-1/2

62.2

23-1/4

59.4

21-7/8

55.6

10-5/8

27.0