ACCESSORY KIT INSTALLATION MANUAL

3500-8941 DOWNFLOW COIL SHELF AND CONDENSATE TRAP PACKAGE

USE WITH MODELS: EB**B SERIES AND EARLIER ELECTRIC FURNACES

Johnson Controls Unitary Products

18585-UAI-C-0708

IMPORTANT -

These instructions are intended for the use by

qualified service technician specially trained and experienced in

installation of this type of equipment and related system compo-

nents.

Installation and service personnel are required by some states

to be licensed.

Persons not qualified shall not install this equipment or interpret

these instructions.

NOTE:

The words “Shall" or “Must" indicate a requirement

which is essential to satisfactory and safe product performance.

The words “Should" or “May" indicate a recommendation or

advice which is not essential and not required but which may be

useful or helpful.

APPLICATION

The 3500-8941 Coil Shelf and Insulation Package is designed

for use on the EB**B Series & 3500 Series electric furnaces for

manufactured homes. This package is required when an air

conditioning or heat pump with an indoor coil is added to the

electric furnace in the downflow configuration.

Some modifications have been made to EB**B electric furnaces

to accept A-Coils with this accessory. All EB series furnaces

manufactured after August 1998 already have these changes

implemented. If this accessory is being installed with an older

EB series furnace, then refer to “Modification Required to Add

A/C to Older EB Furnaces” in these instructions, when adding

air conditioning to the furnace.

NOTE:

Use this coil shelf only in conjunction with Indoor Coils

from a manufacturer which incorporate an auxiliary overflow

tube on the drain pan.

This package contains the following parts:

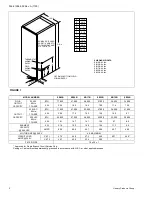

INSTALLATION OF COIL SUPPORT

1.

Remove furnace door.

2.

EB Series - Turn circuit breakers to "OFF". 3500 Series -

Pull furnace disconnect block.

3.

Remove the five blower mounting screws and slide the

blower 1/2 way out of the front of the furnace. (Save

mounting screws.).

4.

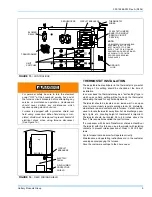

Remove wire clamp screw and remove wire tie. See Figure

1.

5.

Disconnect motor wires from motor and capacitor. See Fig-

ure 1. In some applications motor wires may have to be

disconnected inside the control box of the furnace. For

more information refer to furnace installation instructions.

6.

Slide the blower out of the front of the furnace.

7.

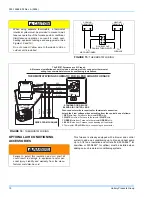

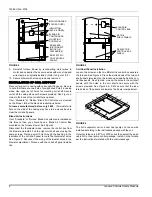

Install insulation tabs to casing sides and back with screws

provided. Screw holes for tabs are located below the two

sets of holes for coil cabinet. See Figure 2.

8.

Install insulation in furnace casing with coated side visible.

Tuck insulation inside casing front edge. Push insulation

tabs through the insulation. Be sure to fold tabs back over

to secure insulation to casing sides and back. See Figure

2. If needed, spray adhesive - 3M Super 77 may be used to

secure insulation to the casing.

Improper installation or service may damage equipment,

can create a hazard and will void the warranty.

The use of other components not tested in combination with

these units may make the equipment in violation of state

codes, may create a hazard and may ruin the equipment. In

addition, the National Mobile Home Construction and Safety

Standards Act and its regulations require the use of compo-

nents tested or certified by a nationally recognized testing

laboratory in all manufactured homes constructed or sold

subject to that act.

Carefully follow all instructions and warnings in this booklet

to avoid damage to the equipment, personal injury or fire.

1 - Insulation Side and Back

1 - Condensate Trap

1 - Coil Shelf

1 - Wire Tie

3 - Insulation Tabs

20 - Sheet Metal Screws

1 - Installation Manual

2 - Hose Clamps

1- Drain Tube

2 - Coil Shelf Panels (Insulated)

SHOCK HAZARD - Be sure to turn the electric power “OFF”

at the main electrical service entrance box, and lock it to

prevent the possibility of personal injury or damage to the

equipment.

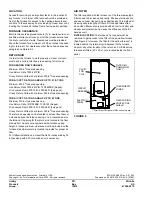

FIGURE 1

WIRE CLAMP

WIRE TIE