unigreen

11

4.5

CARDAN SHAFT

In some models this is supplied on request.

The cardan shaft must bear the CE mark.

It must always have its own instructions that must be followed scrupulously and it

should come with a cover bearing the mark, integrated in every part.

You should have previously checked the length to avoid:

=

if it is too long, DANGEROUS THRUST ON THE PUMP SHAFT

=

if too short, the POSSIBILITY OF DANGEROUS BREAKAGES

THE MINIMUM OVERLAP OF THE TWO

TELESCOPIC TUBES MUST NEVER BE

LESS THAN 1/3 OF THE LENGTH OF

THE TUBES.

The power that can be transmitted by the

cardan shaft must be at least equal to

that required to run the mistblower.

These power ratings are indicated in

tables N° 17a (page 34).

a)

Hook any safety chains to solid anchor points

b)

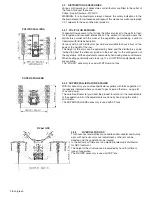

Check that the button or ringnut “E” (FIG. 6) is correctly engaged and blocked

both on the pump side and on the tractor side.

c)

Don’t exceed an inclination of 30° in any direction for any reason

d)

With the machine stopped, periodically grease the spiders and the pipes,

keeping the connecting zone particularly clean.

e)

Avoid letting the end of the cardan shaft come into contact with the ground

with the machine stopped; use the relevant support on some versions for this, if

your machine has no support, hook the external safety chain to a part of the

frame of the machine (ex. control unit support).

f)

For towed mistblowers with a steering drawbar, be very careful not to lift the

arms of the elevator too high to prevent the cardan shaft touching parts of the

drawbar.

l)

For towed mistblowers, avoid very tight steering circles with the cardan shaft

turning (max 30°) as this could damage both the cardan shaft and the feet of the

pump (FIG. 7).

NEVER USE THE CARDAN TRANSMISSION IF THE FOLLOWING

PROTECTIVE COVERS ARE MISSING:

-

TRACTOR POWER-TAKEOFF PROTECTIVE COVER

-

CARDAN SHAFT PROTECTIVE COVER

-

FIXED PROTECTIVE COVER ON THE PUMP SHAFT

4.6

PUMP

When using the pump scrupulously observe the instructions in the enclosed

handbook supplied by the manufacturer.

The pump can be identified by the ratings plate on the same; the main data on the

pressure and delivery are easy to find on this plate.

Normally the pumps mustn’t exceed 550 RPM; a higher speed won’t improve

performance but there is a risk of compromising the life and safety of the pump.

There is a safety valve on the pump, calibrated to prevent overpressure. Don’t

tamper with this valve for any reason and don’t block or obstruct the pipes

connected to it in any way.

4.7

SUCTION FILTER

The sprayer is fitted with a suction filter with filter cartridges that have roughly a

50-gauge mesh, which is equivalent to a hole of 0.4 at 0.35 mm.

An efficient filter lets the sprayer work properly.

You should periodically check that the filter cartridge is clean, this check should

be done more often if there are impurities in the liquid.

To inspect the filter cartridge wear rubber acid-proof gloves as the liquid in the

filter can come into contact with your hands when you open the filter.

Don’t perform this operation with the pump running as the depression produced

blocks the cover preventing the removal.

Before removing the cover of the filter, make sure that the same is isolated from

the tubing by unscrewing the relevant rear valve (FIG. N°8) or on the 3-way

deviator (FIG. N° 10, page 14).

After washing the cartridge, reassemble the cover making sure you connect the

same to the circuit again, using the valves described above in the opposite order.

WARNING!: Don’t disperse the washing residues in the environment!!

FIG. 7

FIG. 6

FIG. 8

Valve

Filter

Содержание TurboTeuton P300

Страница 35: ...unigreen 35 ...