28

Key:

A

limit contact switch for damper OPEN

position

AI

advance signal of a block

AR

main relay (working network) with

contacts “ar”

AS

Monitor fuse

BR

block relay with “br” contacts

BV

fuel valve

EK

reset button

FE

detector electrode of ionisation circuit

FR

flame relay with “fr” contacts

G

ventilator motor or burner motor

GP

gas pressostat

H

main interruptor switch

L

block stoppage LED

LK

damper

LP

air pressostat

LR

safety regulator

M

auxiliary contact switch for damper

“MIN” position

QRA

UV detector

QRE

ignition spark detector

R

thermostat or pressostat

S

fuse

SA

damper servo-motor

SM

synchronous programmer motor

V

flame signal amplifier

V

in case of servo-motor: auxiliary contact

for response to fuel valve re damper

position

W

safety pressostat or thermostat

Z

ignition transformer

Z

in case of servomotor: end of limit

contact switch for damper CLOSED

position

ZBV

pilot burner fuel valve

°

for mono-tube burners

°°

for twin-tube burners

(1

)input for raising QRA detector voltage

to test level

(2)

input for excitation of flame relay during

flame detector

t e s t

circuit (contact XIV) and during safety

time (contact I

V)

(3)

Do not press EK for more than 10

seconds

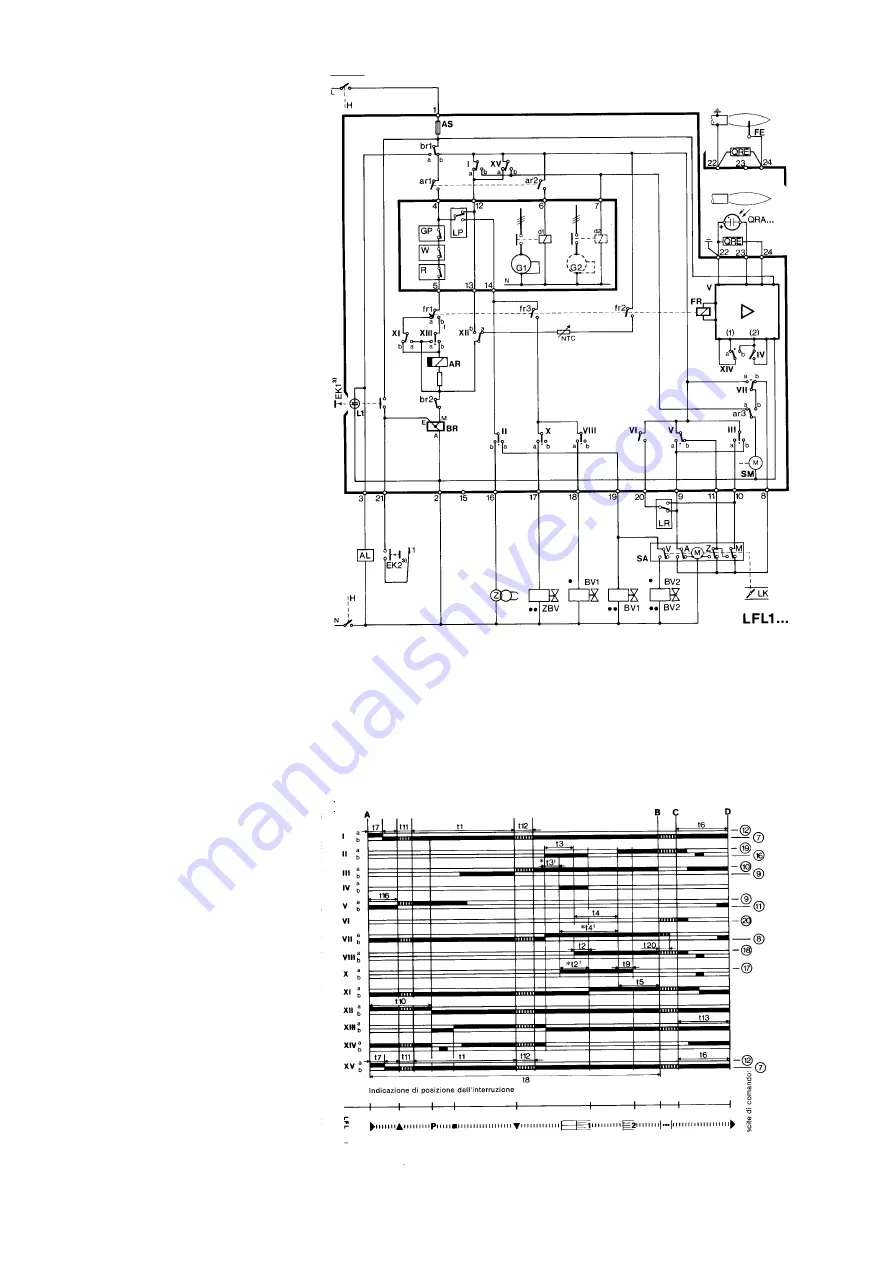

Programmer diagram

t1

pre-ventilation time

t2

safety time

*t2'

1st safety time

t3

pre-ignition time

*t3'

pre-ignition time

t4

interval for creating current between

terminals 18 and 19

*t4'

interval for creating current between

terminals 17 and 19

t5

interval for creating current between

terminals 19 and 20

t6

post-ventilation time

t7

interval between response and current

created at terminal 7

t8

duration of start-up

*t9

2nd safety time

t10

interval before air pressure monitoring

begins

t11

damper opening travel time

t12

damper closure travel time

t13

permissible post-combustion time

t16

initial delay of damper OPEN response

t20

interval before programmer

automatically stops

* These times are valid with the use of a series

01 safety device for monitoring burners with

intermittent pilot lighter.

APPENDIX

Содержание HP60

Страница 4: ......

Страница 5: ......

Страница 24: ...24 MAINTENANCEMANUAL ELECTRICAL DIAGRAM code 05 483 Rev 03...

Страница 25: ...25 MAINTENANCEMANUAL...

Страница 32: ...32 MONARCH OIL NOZZLE Mod F80 BPS APPENDIX...

Страница 33: ...33 BERGNZO OIL ZOZZLE Mod A3 APPENDIX...

Страница 34: ...34 FLUIDICS OIL NOZZLE Mod K3 APPENDIX...

Страница 35: ...35 FLUIDICS OIL NOZZLE Mod KC2 APPENDIX...